Metallic organic frame material for separating CO2 and preparation method thereof

A metal-organic framework and organic ligand technology, which is applied in the field of metal-organic framework materials for efficient separation of CO2 and their preparation, can solve the problems of low selective adsorption and high sensitivity limitation, and achieves simple method, good separation effect, and repeatability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In this example, a mixture of 0.038g cuprous iodide, 0.017g 3,5-pyridinedicarboxylic acid, 5mL dimethyl sulfoxide, 2mL ethanol and 0.02mL hydroiodic acid was added to a 25mL glass bottle for dissolution, and then the lid was closed and sealed , and crystallized in an oven at 90°C for 1 day. After the reaction was completed, the glass bottle was taken out and cooled naturally at room temperature. The crystals formed were removed and washed with ethanol repeatedly for 3 times, and dried at room temperature to obtain blocky green crystals.

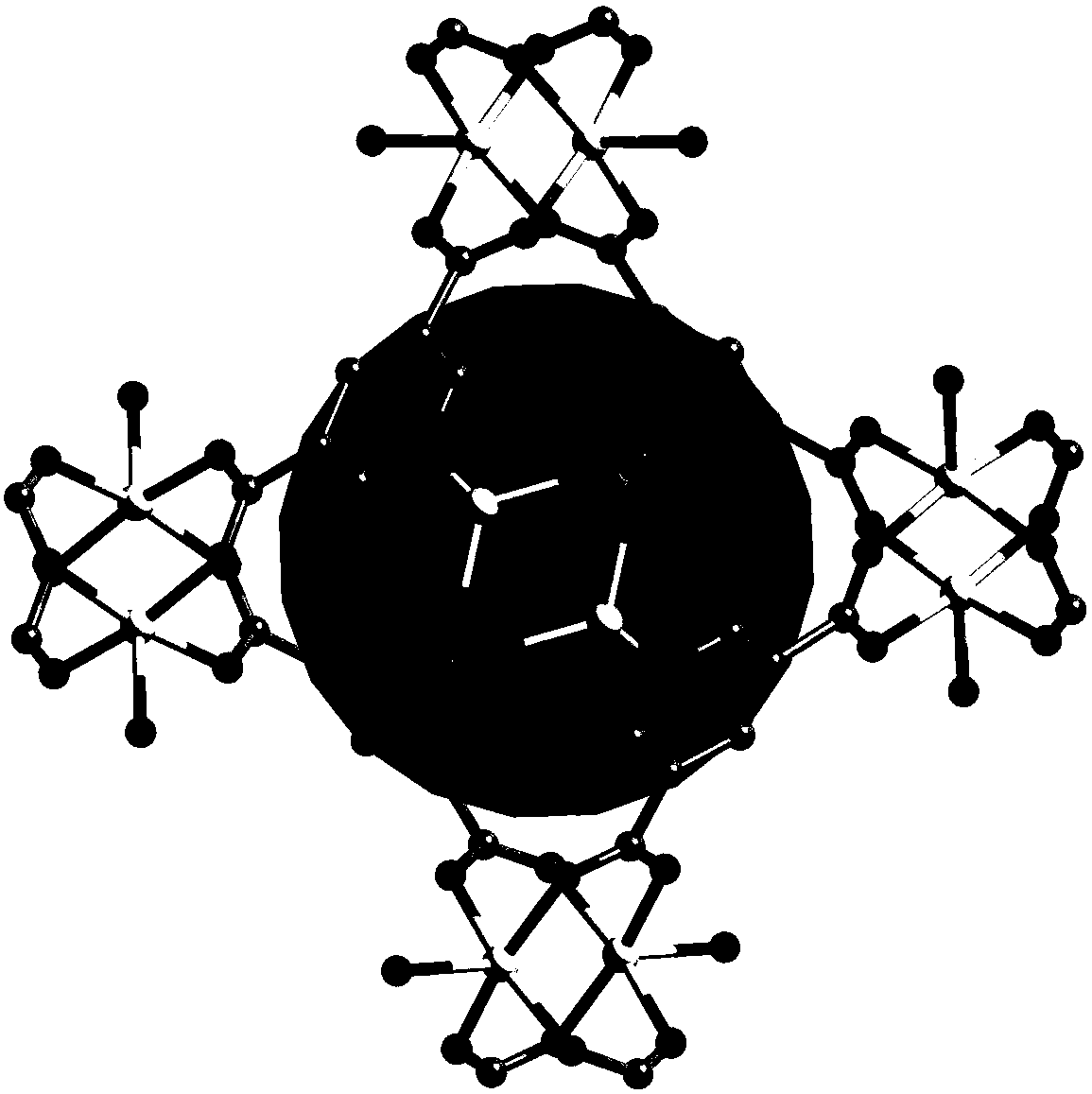

[0022] In this example, single-crystal diffraction was carried out on the prepared massive green crystals, and the data analysis showed that the obtained massive green crystals had a three-dimensional porous structure, and there were two different SBUs in the structure, which were [Cu I 2 I 2 ] and [Cu II 2 (COO) 4 (H 2 O) 2 ], the connection of different types of SBUs with 3,5-pyridinedicarboxylic acid constructed a three-dimens...

Embodiment 2

[0024] In this example, a mixture of 0.038g cuprous iodide, 0.017g 3,5-pyridinedicarboxylic acid, 5mL dimethyl sulfoxide, 2mL ethanol and 0.05mL hydroiodic acid was added to a 25mL glass bottle for dissolution, and then the lid was closed and sealed , crystallized in an oven at 90° C. for 1 day, and after cooling, washing and drying as in Example 1, the characteristics and results of the target product obtained were the same as those in Example 1.

Embodiment 3

[0026] In this example, a mixture of 0.038g cuprous iodide, 0.017g 3,5-pyridinedicarboxylic acid, 5mL dimethyl sulfoxide, 2mL ethanol and 0.08mL hydroiodic acid was added to a 25mL glass bottle for dissolution, and then the lid was closed and sealed , crystallized in an oven at 90° C. for 1 day, and after cooling, washing and drying as in Example 1, the characteristics and results of the target product obtained were the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com