White jade color high borosilicate glass and preparation method thereof

A high borosilicate and glass technology, applied in glass manufacturing equipment, glass furnace equipment, glass production, etc., can solve the problems of changing the internal performance of high borosilicate glass, insufficient chroma of the product, easy to have water marks, etc., and achieve a crystal clear appearance Clear, moderate transparency, anti-acid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The ingredients of jade-colored high borosilicate 3.3 glass are: 8000kg of silicon dioxide, 1200kg of boron, 220kg of alumina, 420kg of sodium chloride, 80kg of calcium carbonate, 20kg of ammonium dihydrogen phosphate, and 20kg of aluminum dihydrogen phosphate, mix well and set aside. The 24-hour feeding capacity is 4800 kg.

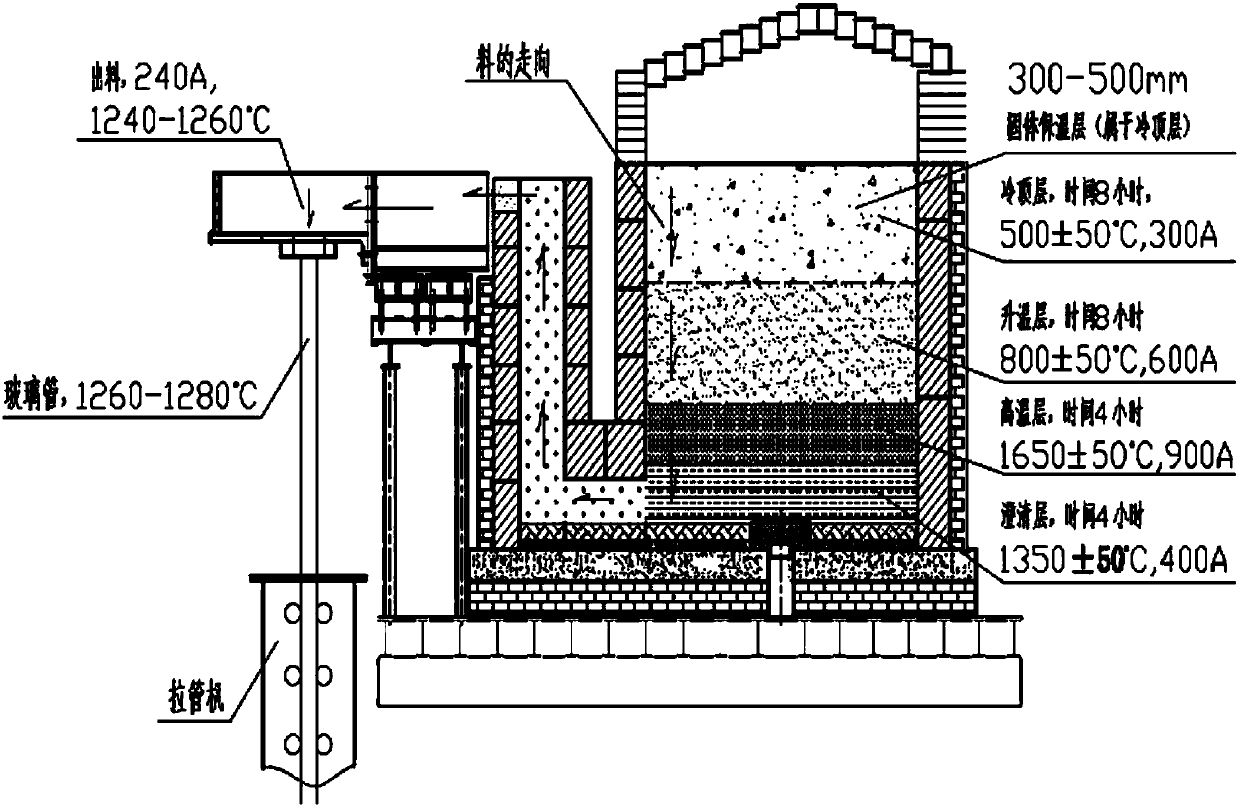

[0057] The product preparation process and flow chart are shown in image 3 :

[0058] (1) Cold top stage: the temperature in the cold top layer of the kiln is maintained at 500°C for 8 hours, the current input to the kiln is about 300A, and ingredients are added every 5-10 minutes to make the top layer of the kiln always have The ingredients of 30-50 cm are in a solid state, forming an insulating layer. The ingredients will flow to the heating layer under the kiln continuously over time, and other ingredients and colorants that start to melt in the heating layer will gradually fuse to ensure coloring The agent is not volatile;

[0059] (2) Hea...

Embodiment 2

[0065] The composition ratio of jade color high borosilicate 3.3 glass rod is: 8060kg of silicon dioxide, 1260kg of boron, 240kg of alumina, 460kg of sodium chloride, 90kg of calcium carbonate, 40kg of ammonium dihydrogen phosphate, 30kg of aluminum dihydrogen phosphate, mix well and set aside. The 24-hour feeding capacity is 6000 kg.

[0066] The product preparation process is:

[0067] (1) Cold top stage: The temperature in the cold top layer of the kiln is maintained at 500°C for 8 hours, the current input to the kiln is about 500A, and ingredients are added every 5-10 minutes so that the top layer of the kiln is always energized. The ingredients of 30-50 cm are in a solid state, forming an insulating layer. The ingredients will flow to the heating layer under the kiln continuously over time, and other ingredients and colorants that start to melt in the heating layer will gradually fuse to ensure coloring The agent is not volatile;

[0068] (2) Heating stage: the temperat...

Embodiment 3

[0074] The ingredients of jade-colored high borosilicate 3.3 glass are: 7500kg of silicon dioxide, 1000kg of boron, 100kg of alumina, 300kg of sodium chloride, 50kg of calcium carbonate, 10kg of ammonium dihydrogen phosphate, and 10kg of aluminum dihydrogen phosphate. The 24-hour feeding capacity is 6000 kg. The product preparation process is:

[0075] (1) Cold top stage: the temperature in the cold top layer of the kiln is kept at 490°C for 8 hours, the current input to the kiln is about 400A, and ingredients are added every 5-10 minutes to make the top layer of the kiln always have The ingredients of 30-50 cm are in a solid state, forming an insulating layer. The ingredients will flow to the heating layer under the kiln continuously over time, and other ingredients and colorants that start to melt in the heating layer will gradually fuse to ensure coloring The agent is not volatile;

[0076] (2) Heating stage: the temperature of the heating layer of the kiln is maintained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com