MEMS viscosity-density sensor chip based on in-plane resonance and preparation method thereof

A density sensor and resonance technology, applied in the field of MEMS sensors, can solve the problems of low measurement accuracy, achieve the effect of improving quality factor, improving stability, good measurement accuracy and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings and through examples.

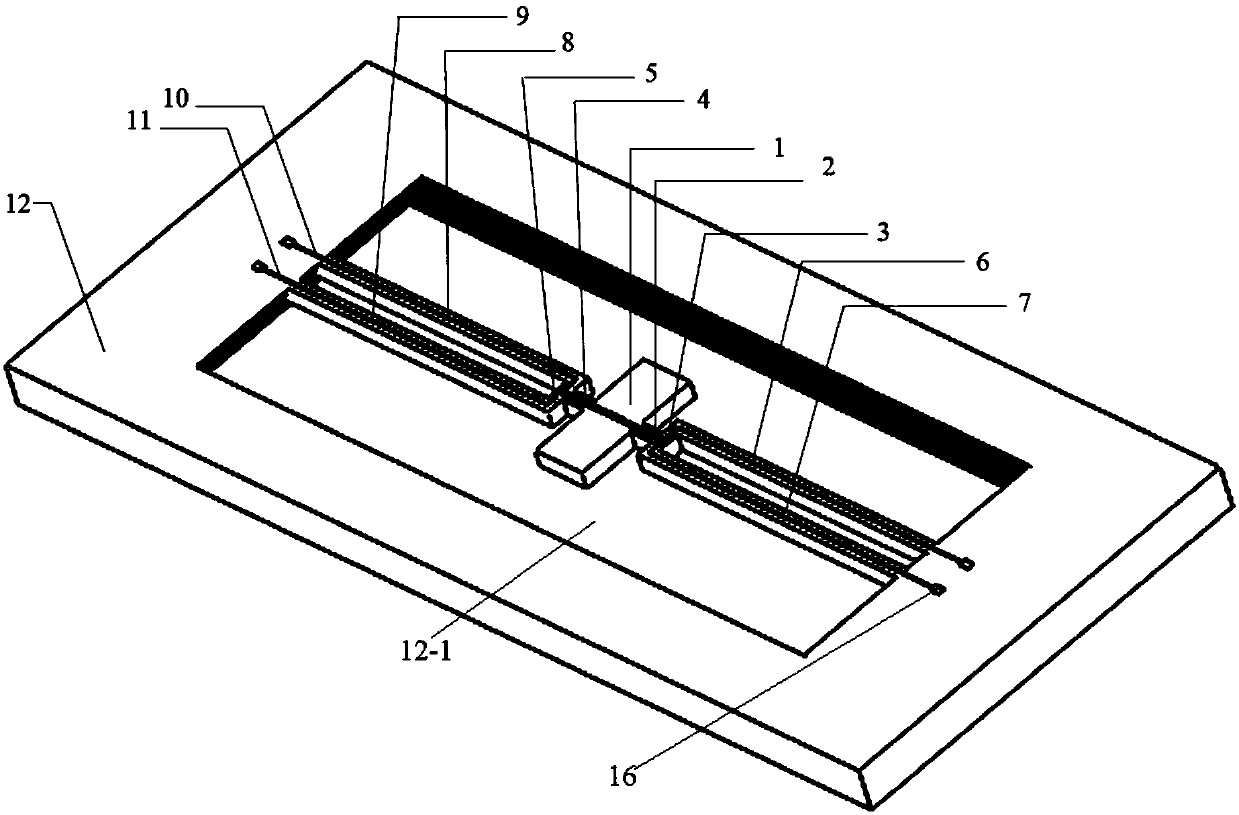

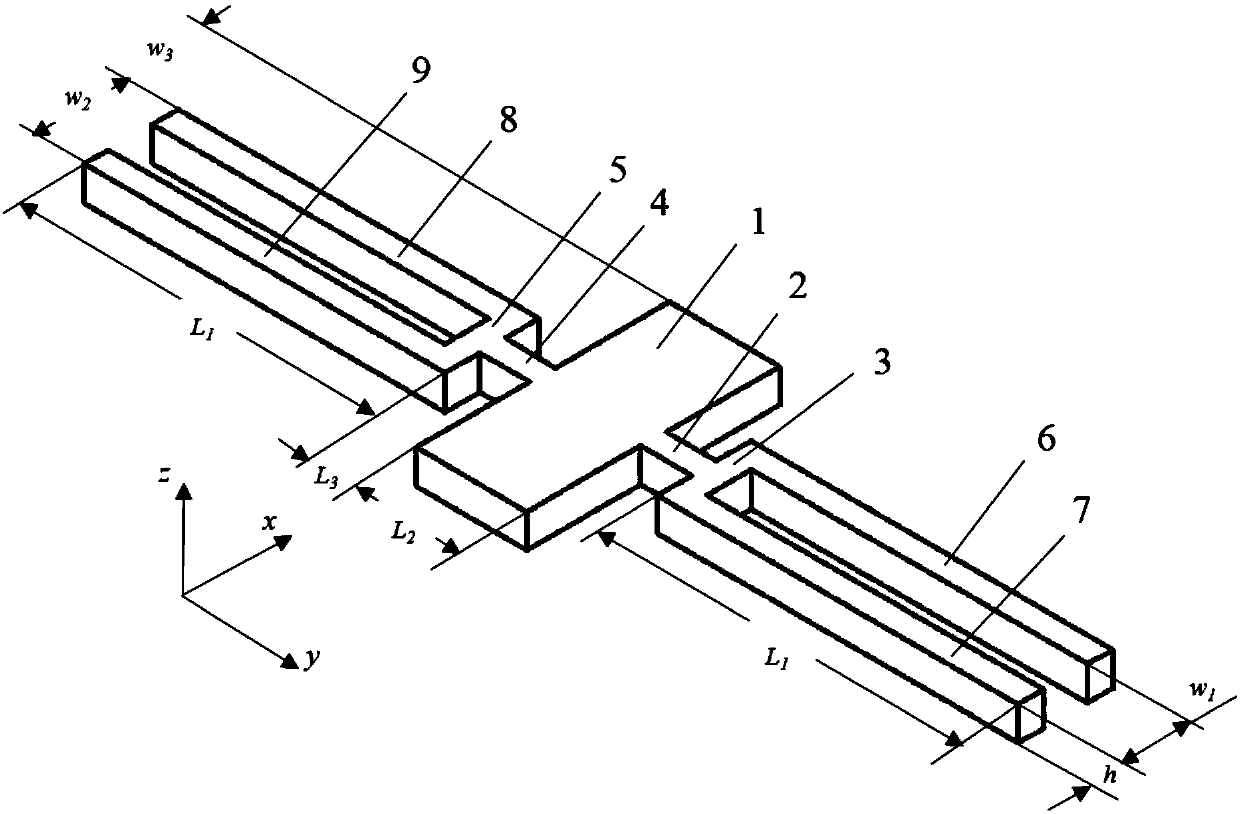

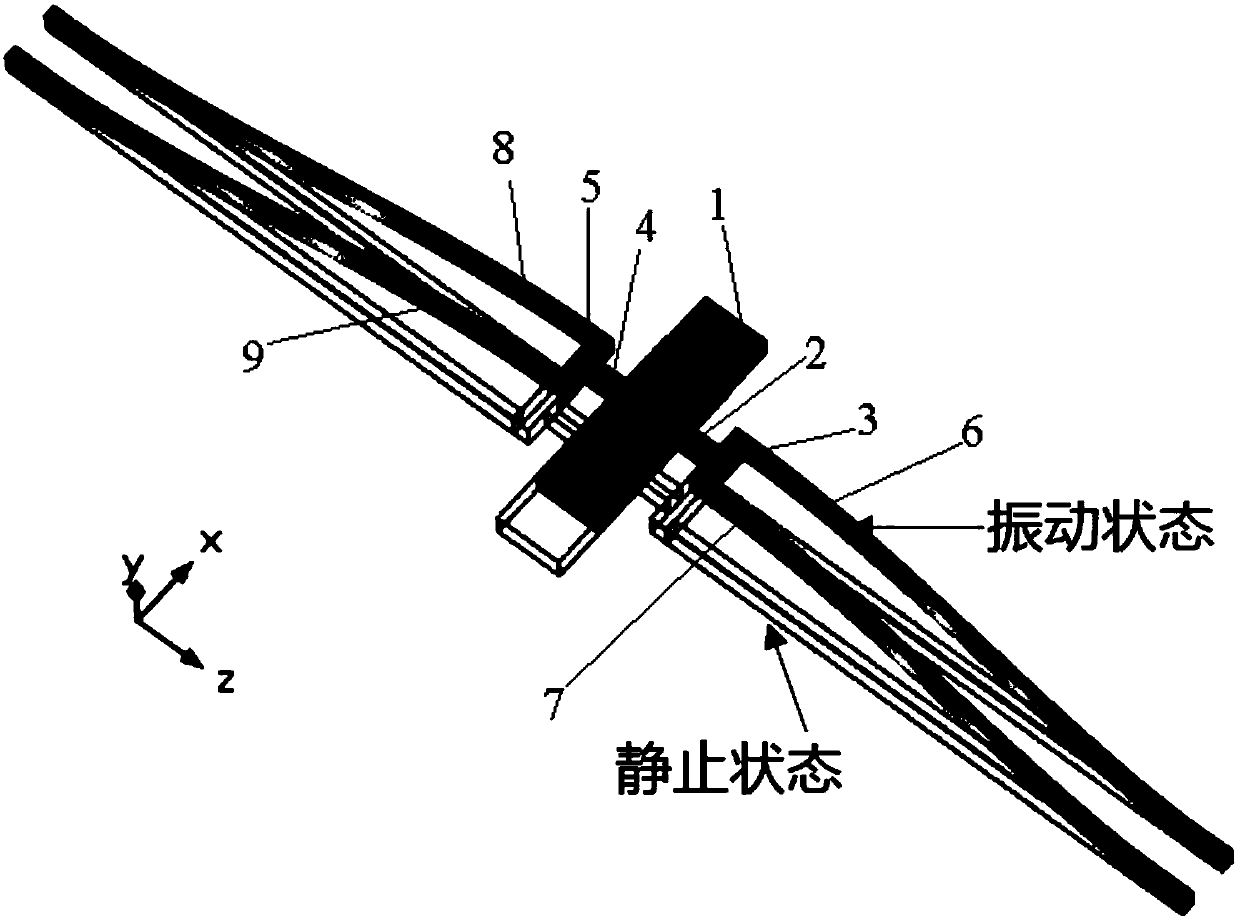

[0048] Such as figure 1 As shown, the MEMS viscosity sensor chip based on in-plane resonance of the present invention is characterized in that it includes a silicon substrate 12, a silicon micro-resonant beam structure and wires, and a window 12-1 is provided on the silicon substrate 12, and the silicon micro-resonant beam structure Set in the window 12-1 and connected to the window 12-1, the silicon substrate 12 is single crystal silicon;

[0049] The silicon micro-resonant beam structure includes a vibrator 1, elastic connecting beams, elastic fixed beams and wires;

[0050] The elastic connecting beam includes the first elastic connecting beam 2, the second elastic connecting beam 3, the third elastic connecting beam 4 and the fourth elastic connecting beam 5; the elastic fixed beam includes the first elastic fixed beam 6, the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com