A kind of preparation technology of multi-layer structure 3D abrasive tool

A multi-layer structure and preparation technology, which is applied in the direction of grinding/polishing equipment, grinding devices, manufacturing tools, etc., can solve the problems of grinding debris clogging, and achieve the goal of avoiding grinding debris clogging, ensuring continuity and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

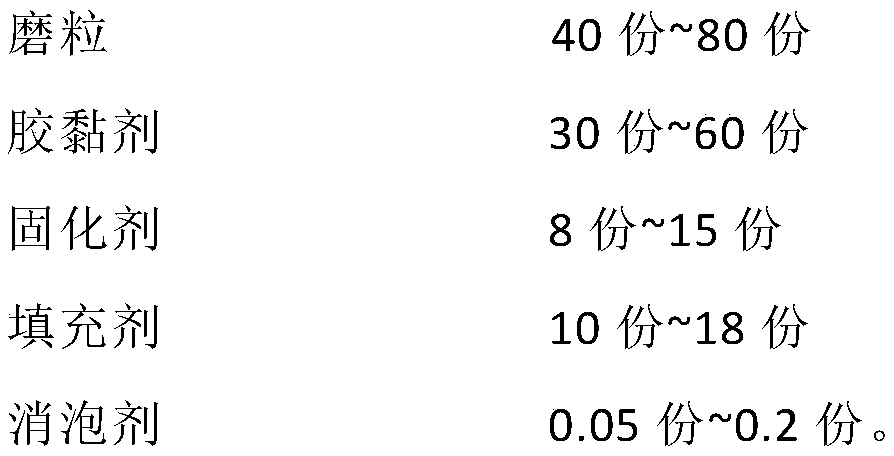

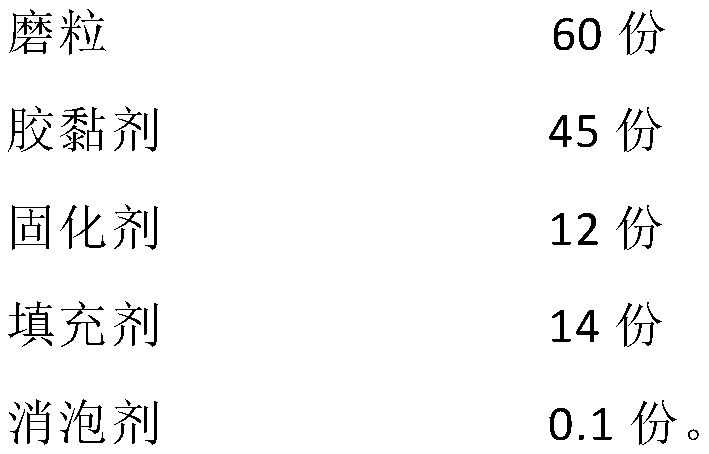

Embodiment 1

[0035] A kind of preparation technology of multi-layer structure 3D grinding tool, it comprises the following steps:

[0036] Step 1. Coating primer on the elastic film: apply a primer layer on the surface of the elastic film, and then initially cure and keep the primer layer with a certain viscosity; in this embodiment, the curing temperature for initial curing is 90°C , the curing time is 22s;

[0037] Step 2. Compression of the frame: place a frame with a height of 0.50mm on the primer layer, and then compress it;

[0038] Step 3. Scratch abrasive: scrape the abrasive into the frame according to the thickness of the frame;

[0039] Step 4. Preliminary curing of the abrasive: Preliminarily solidify the abrasive in step 3 to form an abrasive layer with a thickness of 0.30 mm, and make the abrasive layer in a thick and non-sticky state; in this embodiment, the curing temperature for the preliminary curing is 110°C. The curing time is 4min;

[0040] Step 5, compression moldi...

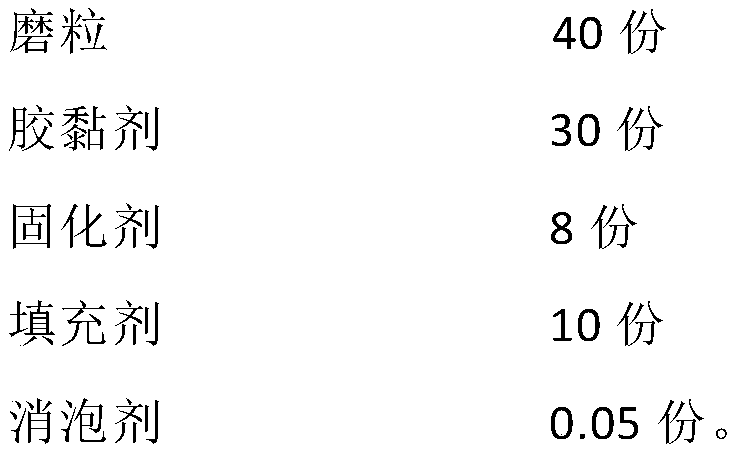

Embodiment 2

[0050] A kind of preparation technology of multi-layer structure 3D grinding tool, it comprises the following steps:

[0051] Step 1. Coating primer on the elastic film: apply a primer layer on the surface of the elastic film, and then initially cure and keep the primer layer with a certain viscosity; in this embodiment, the curing temperature for initial curing is 80°C , curing time is 30s;

[0052] Step 2. Compression of the frame: place a frame with a height of 0.10mm on the primer layer, and then compress it;

[0053] Step 3. Scratch abrasive: scrape the abrasive into the frame according to the thickness of the frame;

[0054] Step 4. Preliminary curing of the abrasive: Preliminarily solidify the abrasive in step 3 to form an abrasive layer with a thickness of 0.05 mm, and make the abrasive layer thick and not sticky; in this embodiment, the curing temperature for the preliminary curing is 100°C. The curing time is 5 minutes;

[0055] Step 5, compression molding: place ...

Embodiment 3

[0065] A kind of preparation technology of multi-layer structure 3D grinding tool, it comprises the following steps:

[0066] Step 1. Coating primer on the elastic film: apply a primer layer on the surface of the elastic film, and then initially cure and keep the primer layer with a certain viscosity; in this embodiment, the curing temperature for initial curing is 100°C , curing time is 15s;

[0067] Step 2. Compressing the frame: place a frame with a height of 1.0mm on the primer layer, and then compress it;

[0068] Step 3. Scratch abrasive: scrape the abrasive into the frame according to the thickness of the frame;

[0069] Step 4. Preliminary curing of the abrasive: Preliminary curing of the abrasive in step 3 to form an abrasive layer with a thickness of 0.50 mm, and make the abrasive layer in a thick and non-sticky state; in this embodiment, the curing temperature for the preliminary curing is 120°C. The curing time is 3 minutes;

[0070] Step 5, compression molding:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com