Medium-temperature and high-pressure wax preparing device

A preparation device and high pressure technology, applied in casting and molding equipment and other directions, can solve the problems of the medium temperature wax not reaching the temperature, the influence of the investment casting process, and the blockage of the medium temperature wax pipeline, so as to improve the service life, improve the wax injection process, prevent the blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

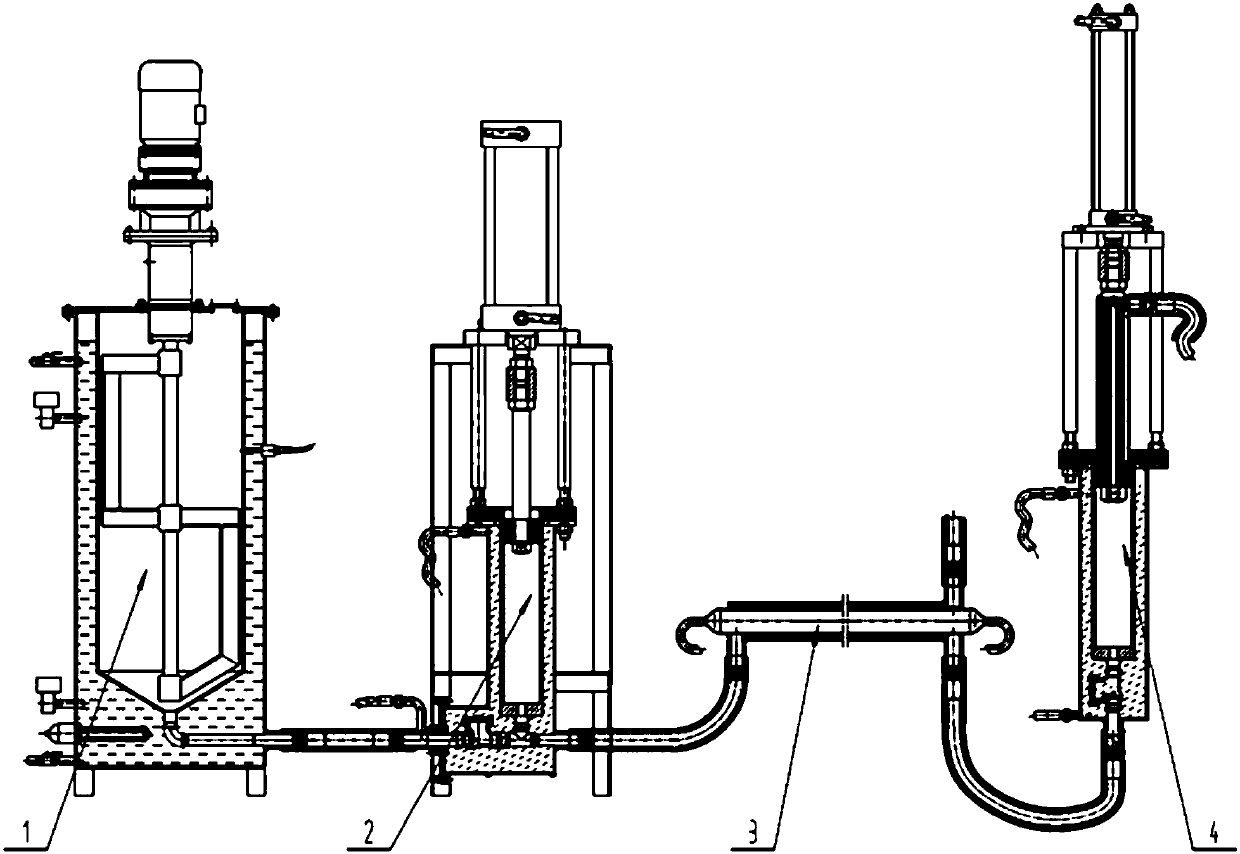

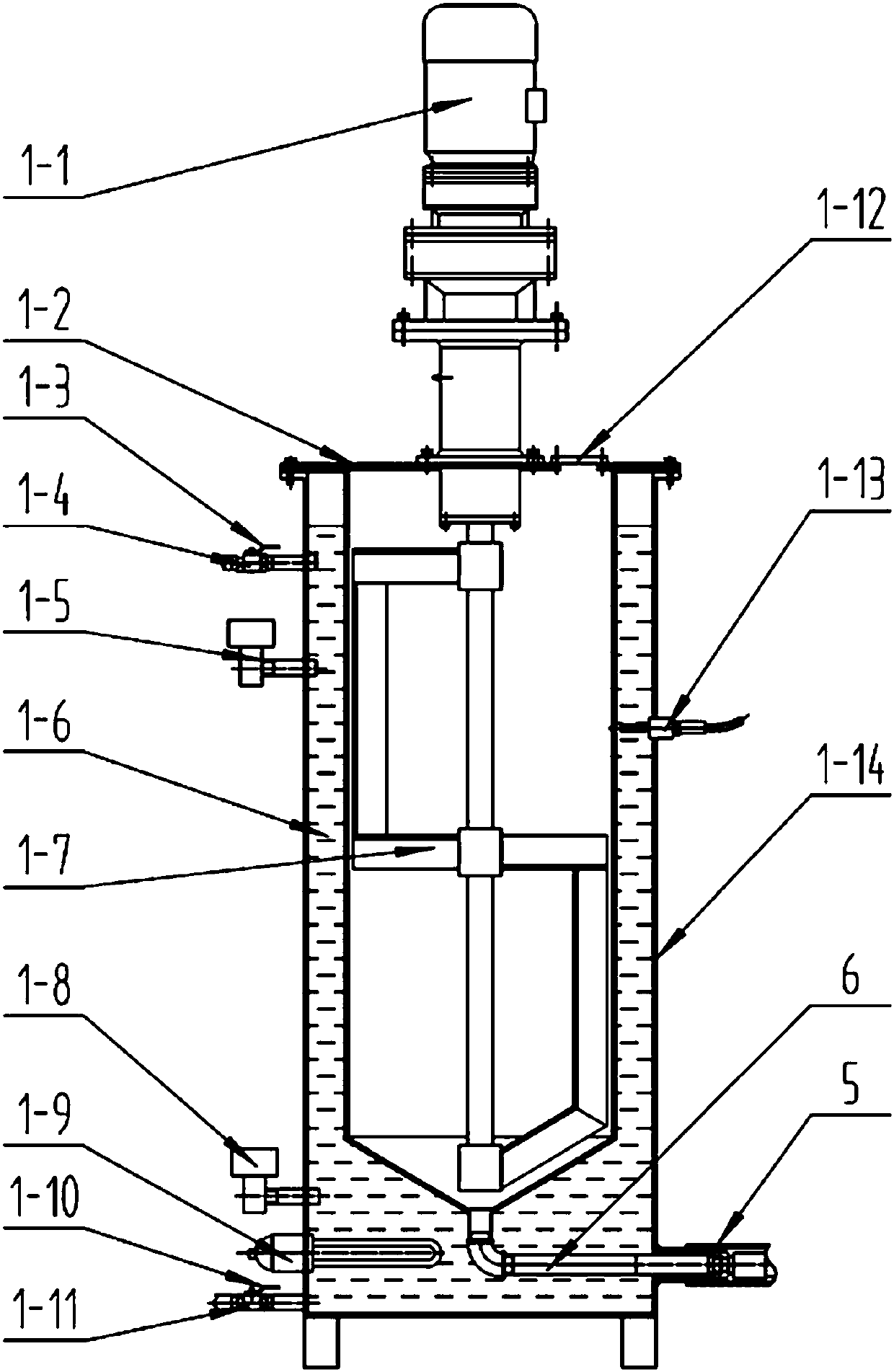

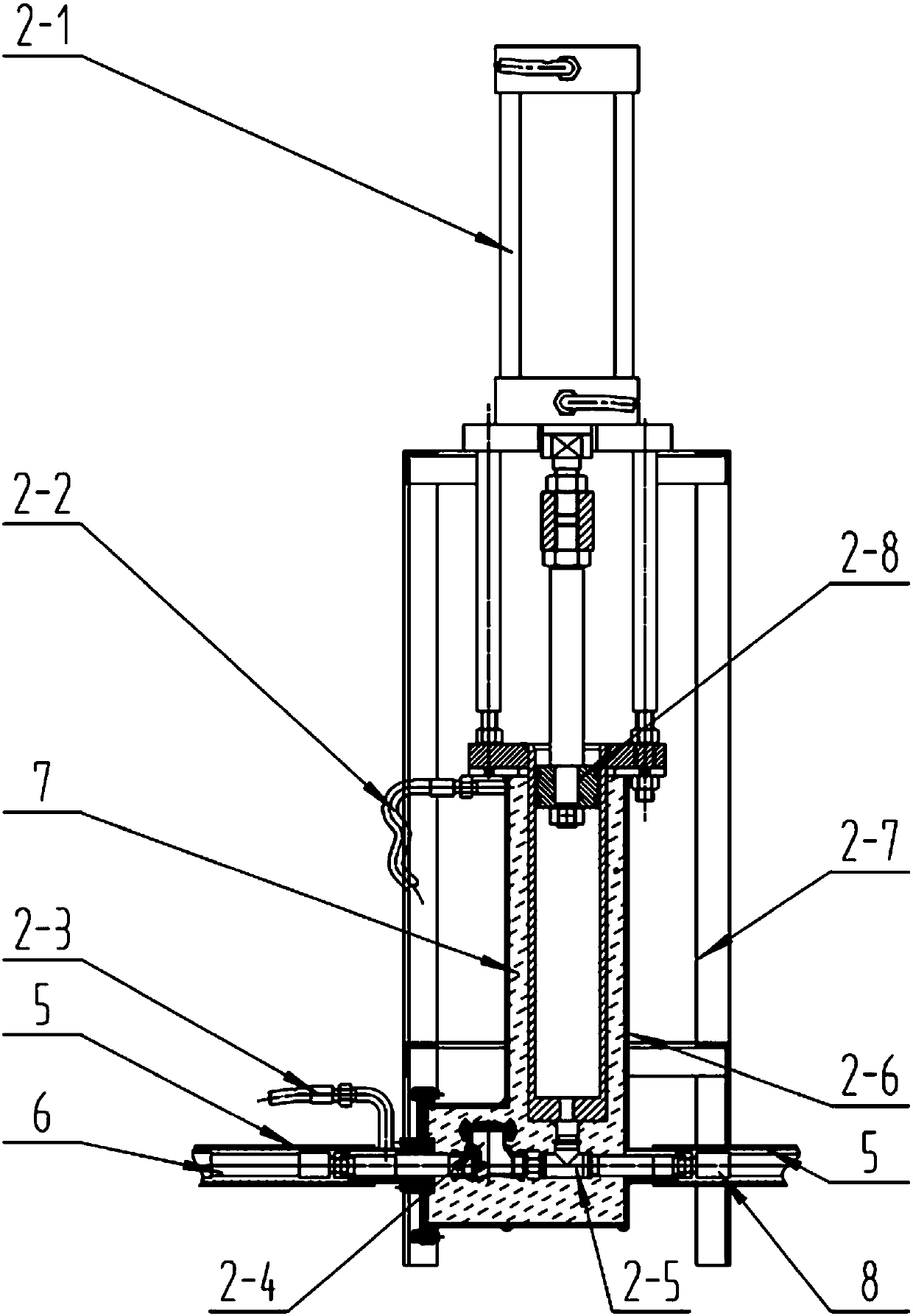

[0023] Such as figure 1As shown, a kind of medium-temperature high-pressure wax preparation device of the present invention comprises primary emulsion wax system 1, initial pressurization system 2, emulsion wax system 3, secondary pressurization system 4, heat preservation medium II preparation system 10, heat preservation cover 5, suction Wax pipe 6, heat preservation medium II7, low-pressure wax outlet pipe 8, cream wax outlet pipe 9, primary emulsion wax system 1 includes stirring motor 1-1, initial emulsion wax tank 1-2, insulation medium I inlet pipe switch 1-3, Heat preservation medium I inlet pipe 1-4, cooling solenoid valve I1-5, heat preservation medium I1-6, stirring blade 1-7, cooling solenoid valve II1-8, heating pipe I1-9, heat preservation medium I outlet switch 1-10 , Insulation medium I outlet pipe 1-11, wax injection port 1-12, thermometer I1-13, insulation tank I1-14, initial pressurization system 2 includes primary pressurization cylinder 2-1, insulation med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com