Anti-blocking type metal powder grinding device for cemented carbide processing

A technology of metal powder and hard alloy, which is applied in the field of anti-blocking type hard alloy processing metal powder grinding device, can solve problems such as difficulty in taking materials, affecting production efficiency, and blockage of sieve holes, so as to improve efficiency and save sampling Time and cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

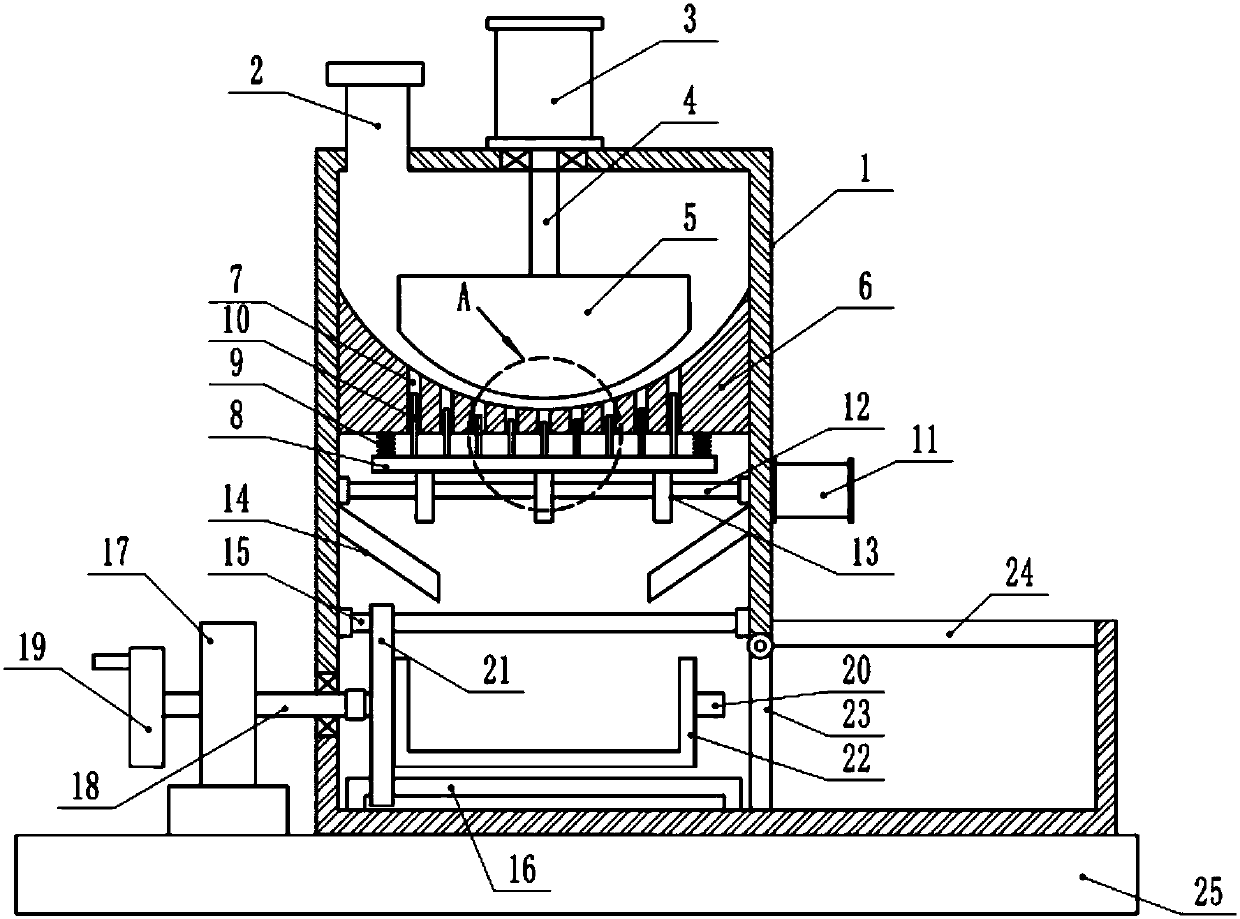

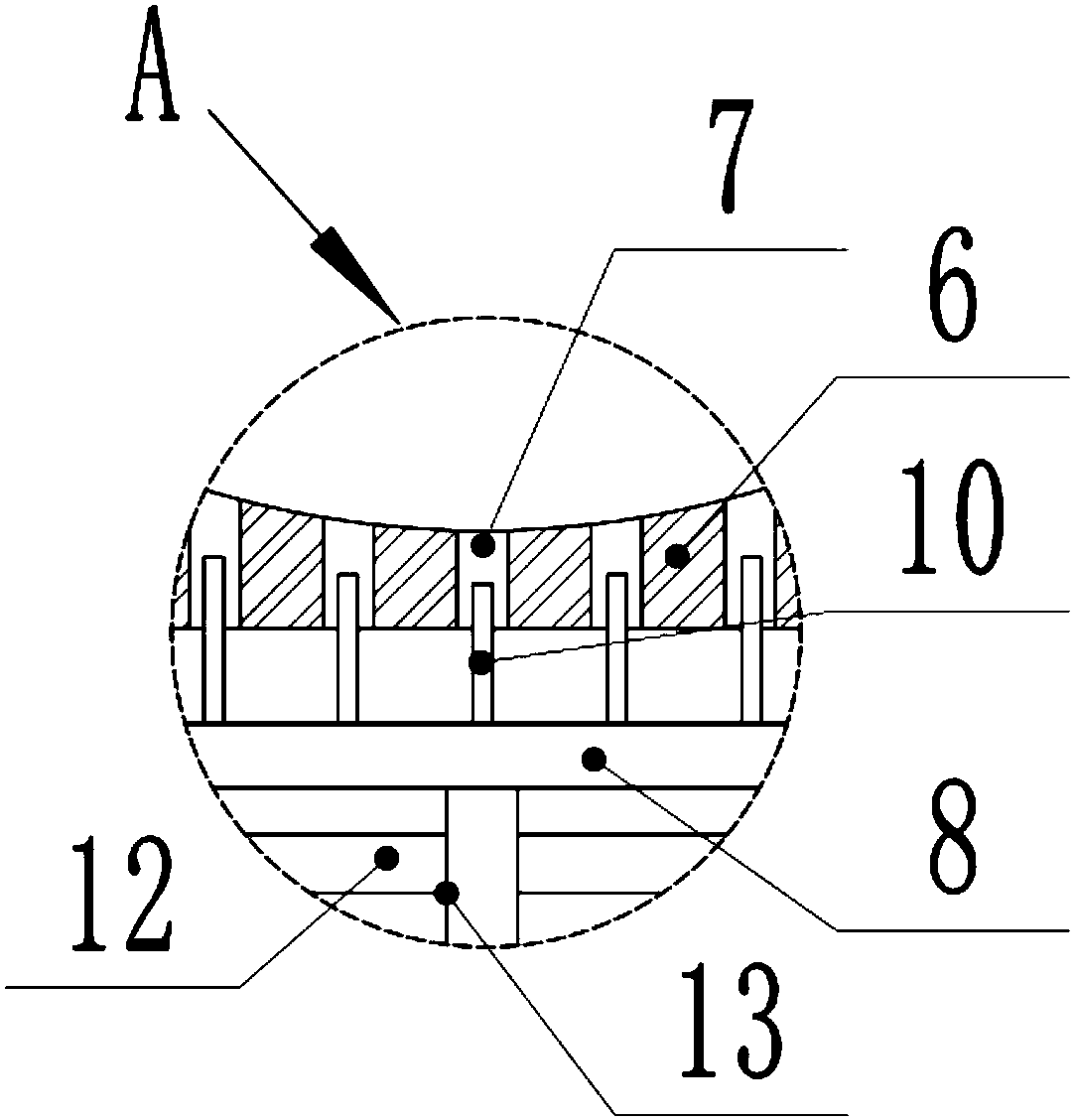

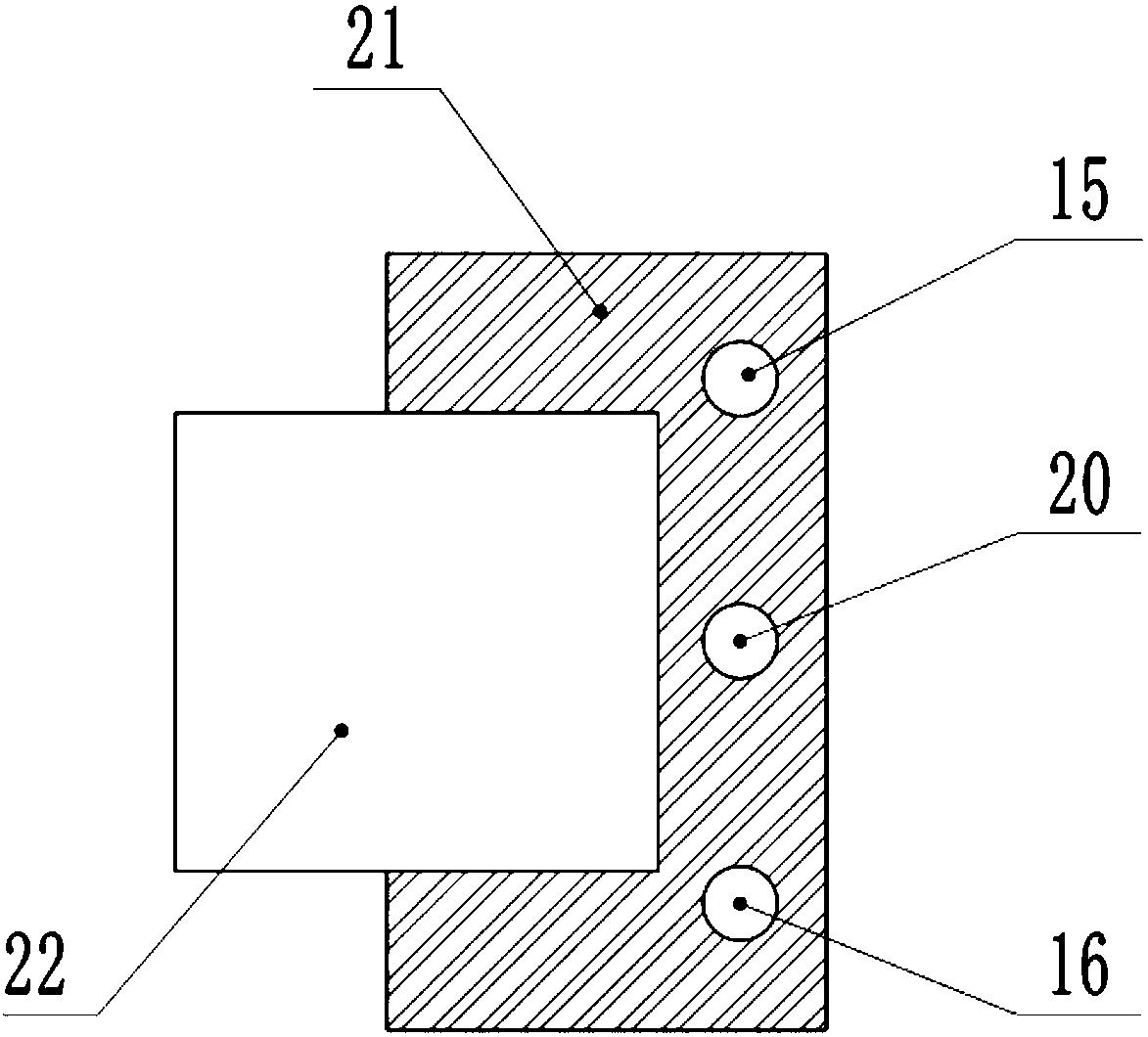

[0020] see Figure 1-3 , an anti-blocking metal powder grinding device for processing hard alloys, comprising a grinding machine case 1, a grinding motor 3, a grinding head 5, a grinding sieve plate 6, a porosity needle 10, a cam 13 and a receiving box 22, the base 25 There is a grinding machine box 1 on the top, and the grinding machine box 1 and the base 25 are fixedly connected by screws. There is a powder feeding port 2 on the left side of the grinding machine box 1, and the powder feeding port 2 is connected with an external feeding device. The grinding machine box 1 A grinding motor 3 is also fixedly installed at the center of the upper side, the output shaft of the grinding motor 3 is vertically downward and penetrates into the inside of the grinding machine box 1, the output shaft of the grinding motor 3 is connected with the grinding shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com