Vacuum degreasing sintering furnace

A technology of vacuum degreasing and sintering furnace, which is applied in the direction of furnace, furnace type, lighting and heating equipment, etc., can solve the problems of low production efficiency, and achieve the effect of high production efficiency and high marriage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

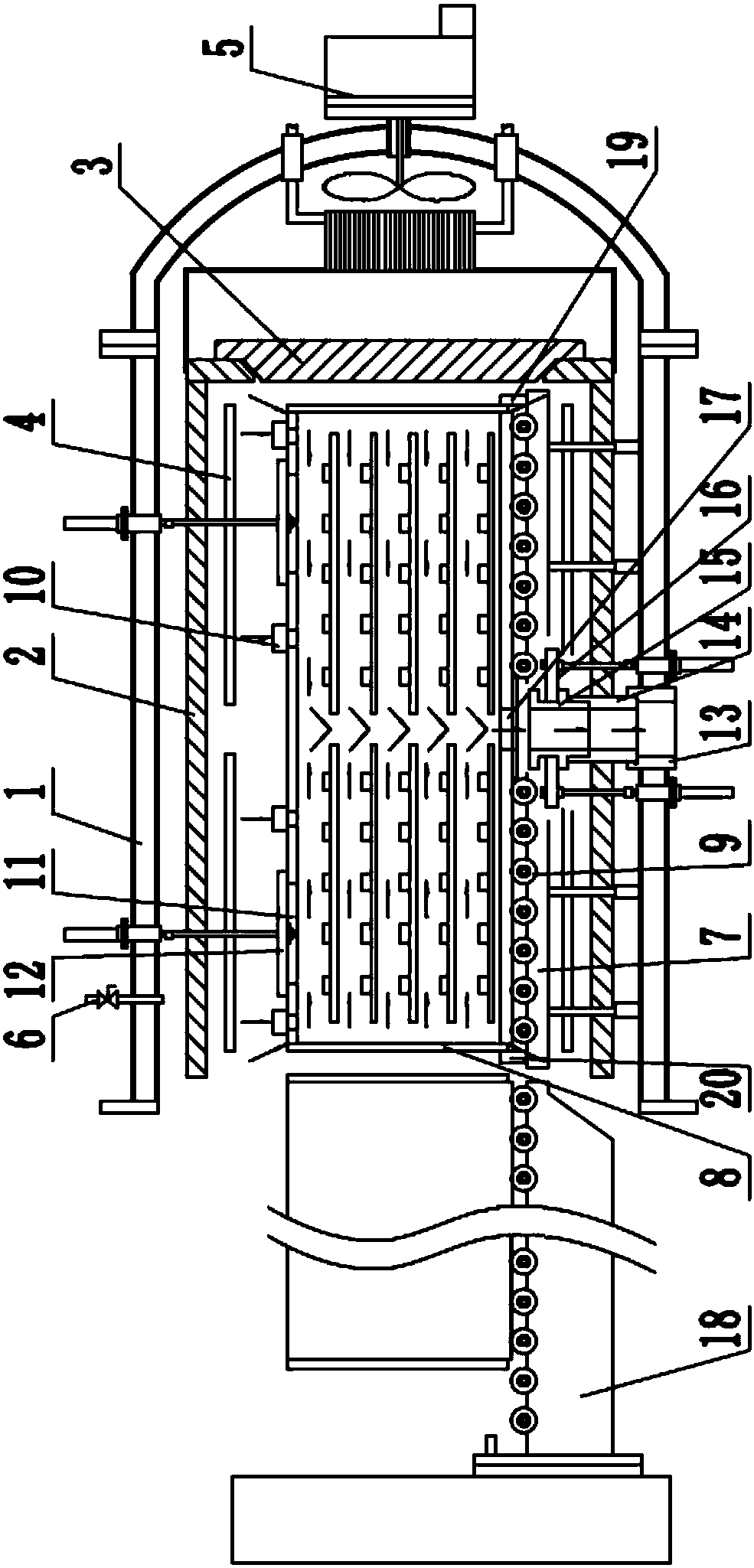

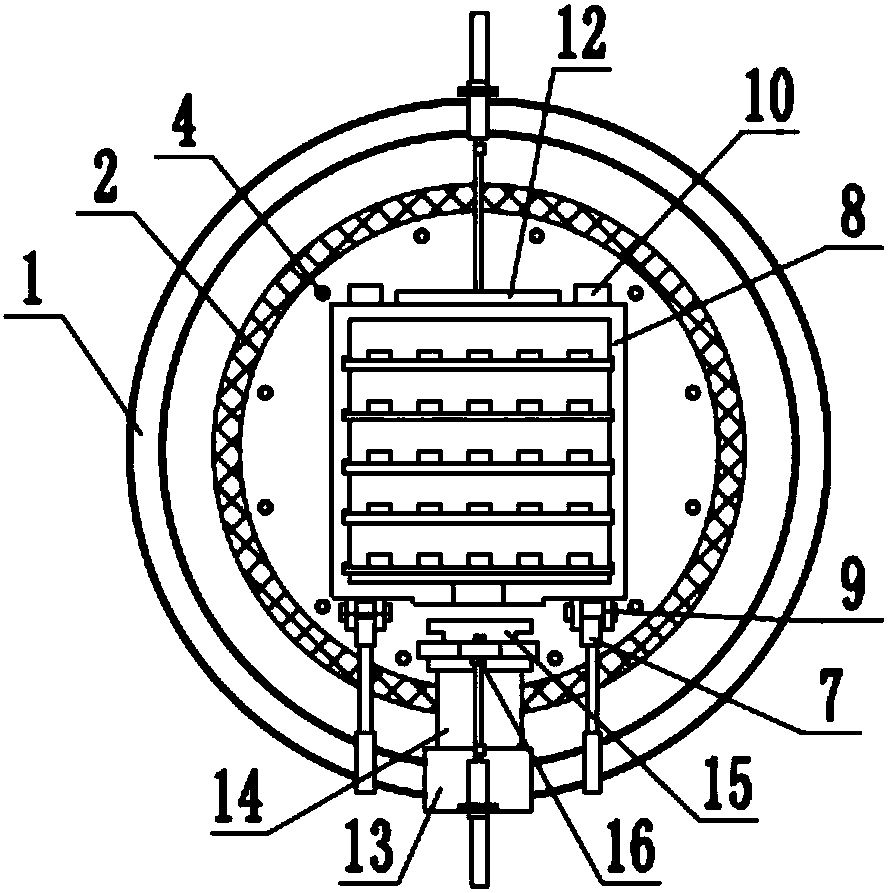

[0033] Embodiment 1: as Figure 1-2As shown, this embodiment provides a vacuum degreasing sintering furnace, including a furnace body 1 and a heat insulation cylinder 2 and an insulation door 3 arranged in the furnace body 1, the heat insulation cylinder 2 and the heat insulation door 3 are made of heat insulation materials In this way, the insulation door 3 is arranged on the two ends of the heat insulation cylinder 2, and the insulation door 3 is connected with the furnace door as a whole, which can be opened and closed. The inside of the heat-insulating cylinder 2 is provided with a heating body 4, and the heating of the heating body 4 can radiate the material box 8 to heat up. One end of body of heater 1 is hinged with furnace door (not in figure 1 In drawing), the other end of the furnace body 1 is also hinged with a furnace door, and a cooling system 5 is provided on the furnace door. The cooling system 5 includes a fan, an impeller and a cooler, the fan is arranged on...

Embodiment 2

[0039] Embodiment 2: as Figure 5 As shown, the present embodiment provides a vacuum degreasing sintering furnace, including a first furnace body 22, a second furnace body 23 and a third furnace body 24 connected end to end in sequence, the first furnace body 22 is used to perform a degreasing process, and the second furnace body 22 is used to perform a degreasing process. The second furnace body 23 is used for performing the sintering process, and the third furnace body 24 is used for performing the cooling process.

[0040] The front end of the first furnace body 22 and the tail end of the third furnace body 24 are hinged with a furnace door 25, which can be opened to facilitate the loading and unloading of the material box 8 by the skip truck 18. The inside of the second furnace body 23 is provided with a heat-insulating cylinder 2, and the inside of the heat-insulating cylinder 2 is provided with a heating body 4. The two ends of the second furnace body 23 are movably conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com