Manufacturing method of metal-plastic multilayer photomask

A technology of metal plastics and manufacturing methods, which is applied in the direction of metal layered products, chemical instruments and methods, and originals for photomechanical processing, etc., can solve the problems of high unit price and high probability of damage of a single metal mask, and achieve increased adhesion effect , The effect of increasing the marriage rate and prolonging the replacement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

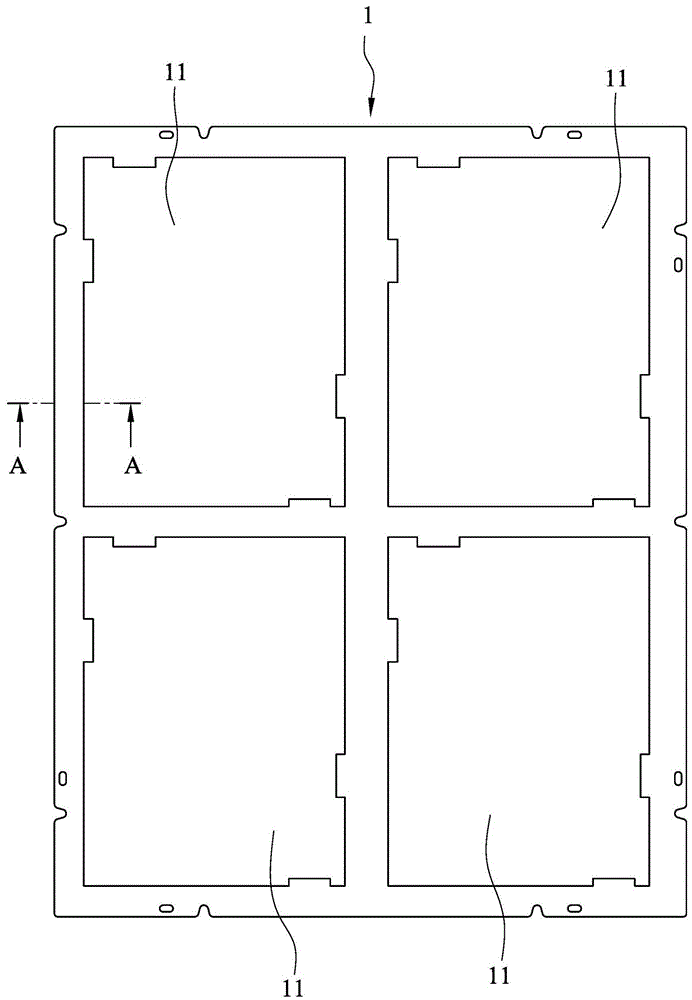

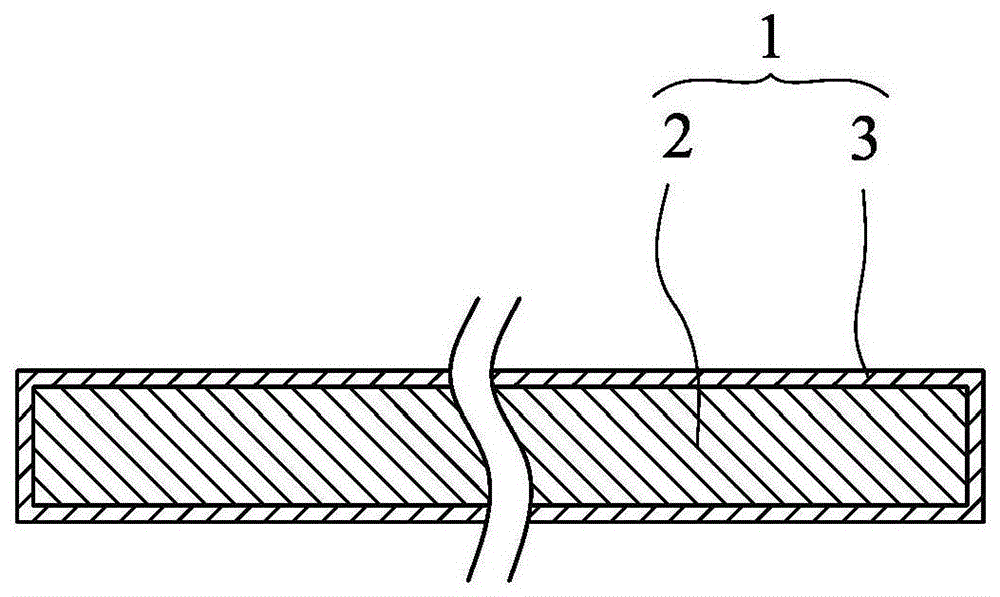

[0035] figure 1 and figure 2 Shown is a plan view and a partial section enlarged view of the present invention. The present invention is a metal-plastic multi-layer photomask 1, which is mainly used in the manufacturing process of optoelectronic products. On the substrate to be processed, a film with a specific pattern is deposited on a substrate to be processed. The substrate is a material containing silicon or glass. , such as the substrate of a liquid crystal screen. The multi-layer photomask 1 is a sheet-shaped frame, and at least one pattern unit 11 is formed through the frame. The contour shape of the pattern unit 11 is the shape corresponding to the aforementioned specific pattern, and the specific pattern depends on the manufacturer's requirements. It is convenient to deposit the corresponding thin film on the substrate in the manufacturing process of optoelectronic products.

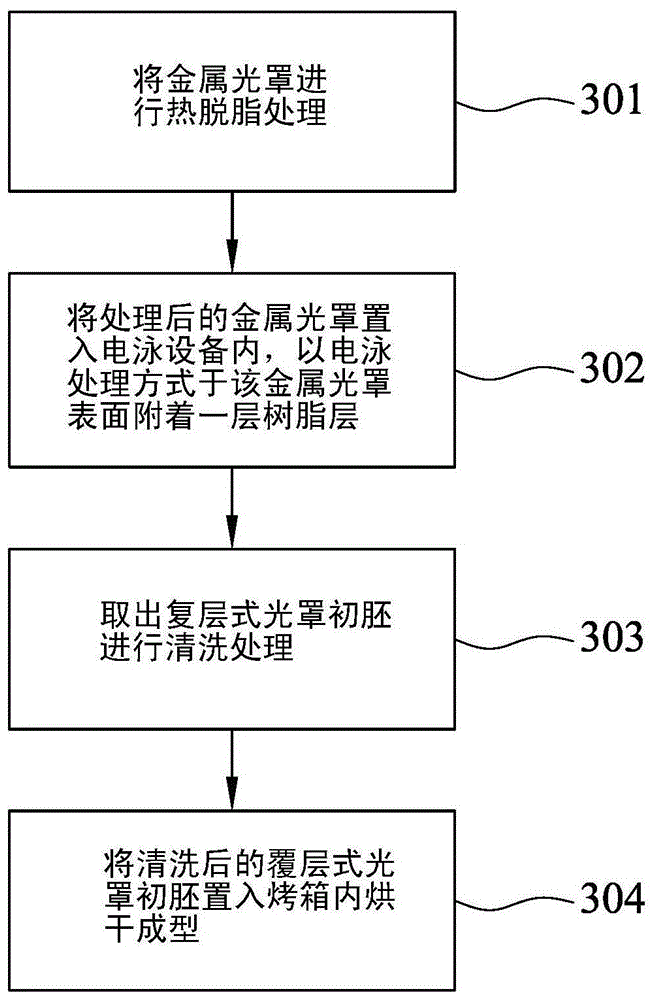

[0036] The main improvement of the present invention is to design the multi-layer photom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com