Glass fiber treatment agent for surface spraying treatment of glass fiber plastic parts and its application

A technology of surface spraying and plastic parts, applied in the direction of coating, etc., can solve the problems of poor hiding power and corrosion resistance, low product yield, easy to produce floating fibers, etc., achieve strong hiding power, prevent solvent penetration, and reduce online spraying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

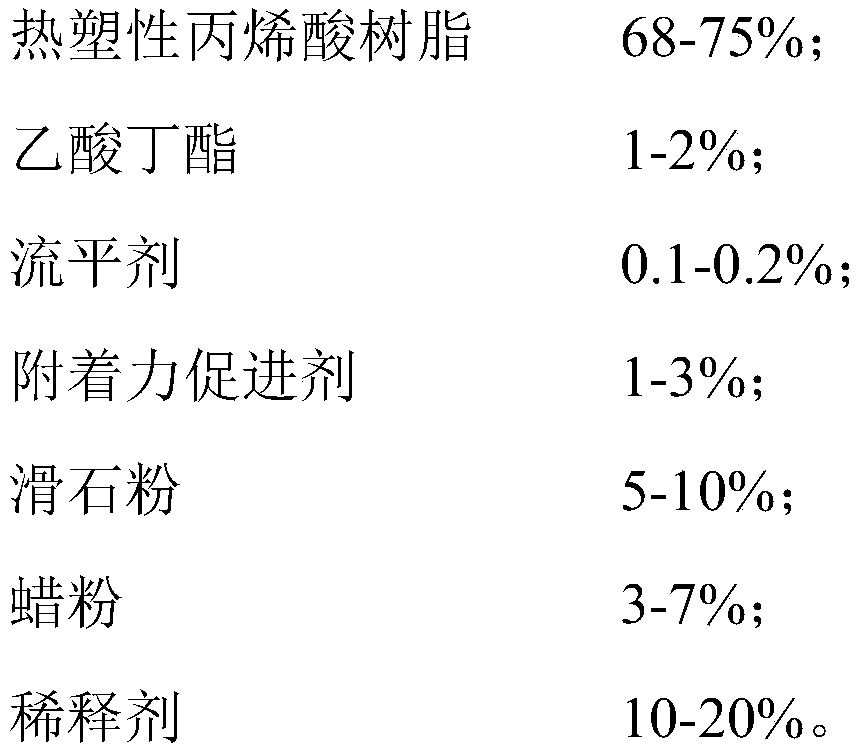

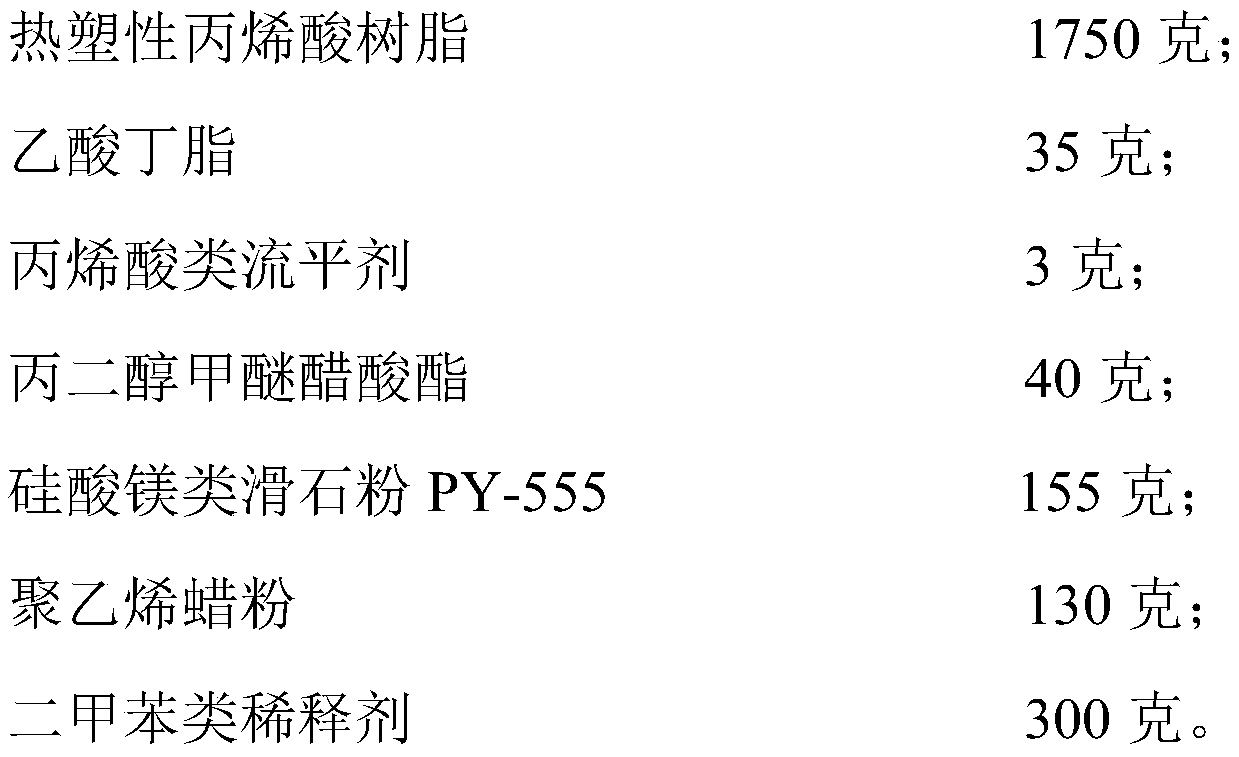

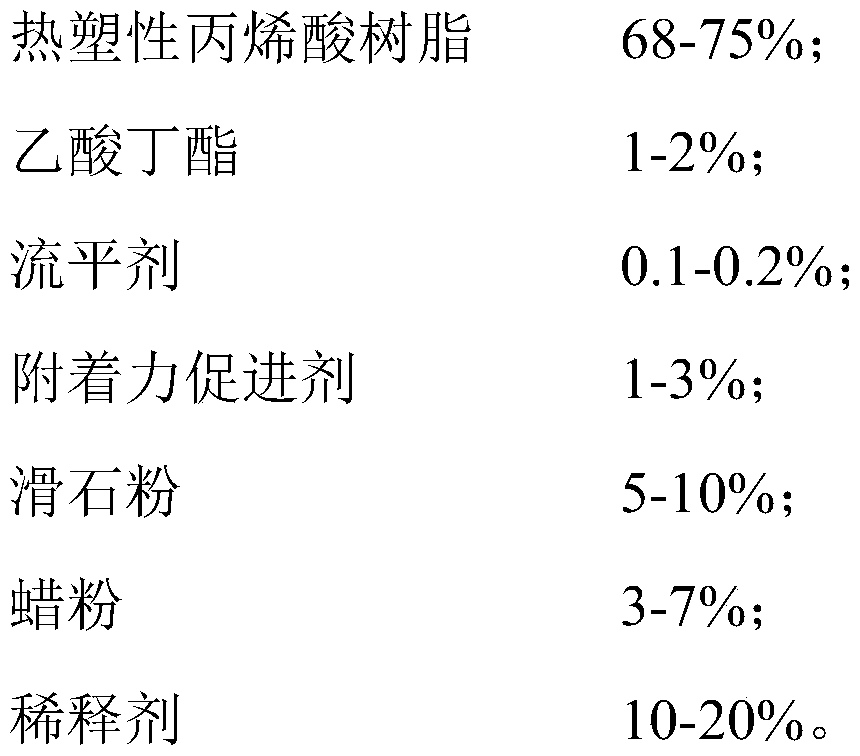

[0032] An embodiment of the present invention provides a glass fiber treatment agent for spraying the surface of plastic parts, based on the total mass of the glass fiber treatment agent for spraying the surface of plastic parts as 100%, including the following mass percentages of the following components:

[0033]

[0034] Specifically, in the embodiment of the present invention, the thermoplastic acrylic resin plays an important role as the main component of the glass fiber treatment agent used for spraying the surface of plastic parts. Specifically, the thermoplastic acrylic resin no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com