Method for preparing silicon modified carrier and desoxidant prepared from carrier and desoxidant preparation method

A technology of silicon modification and deoxidizer, applied in catalyst carriers, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as evaporation, avoid falling off, and ensure the content of silicon. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

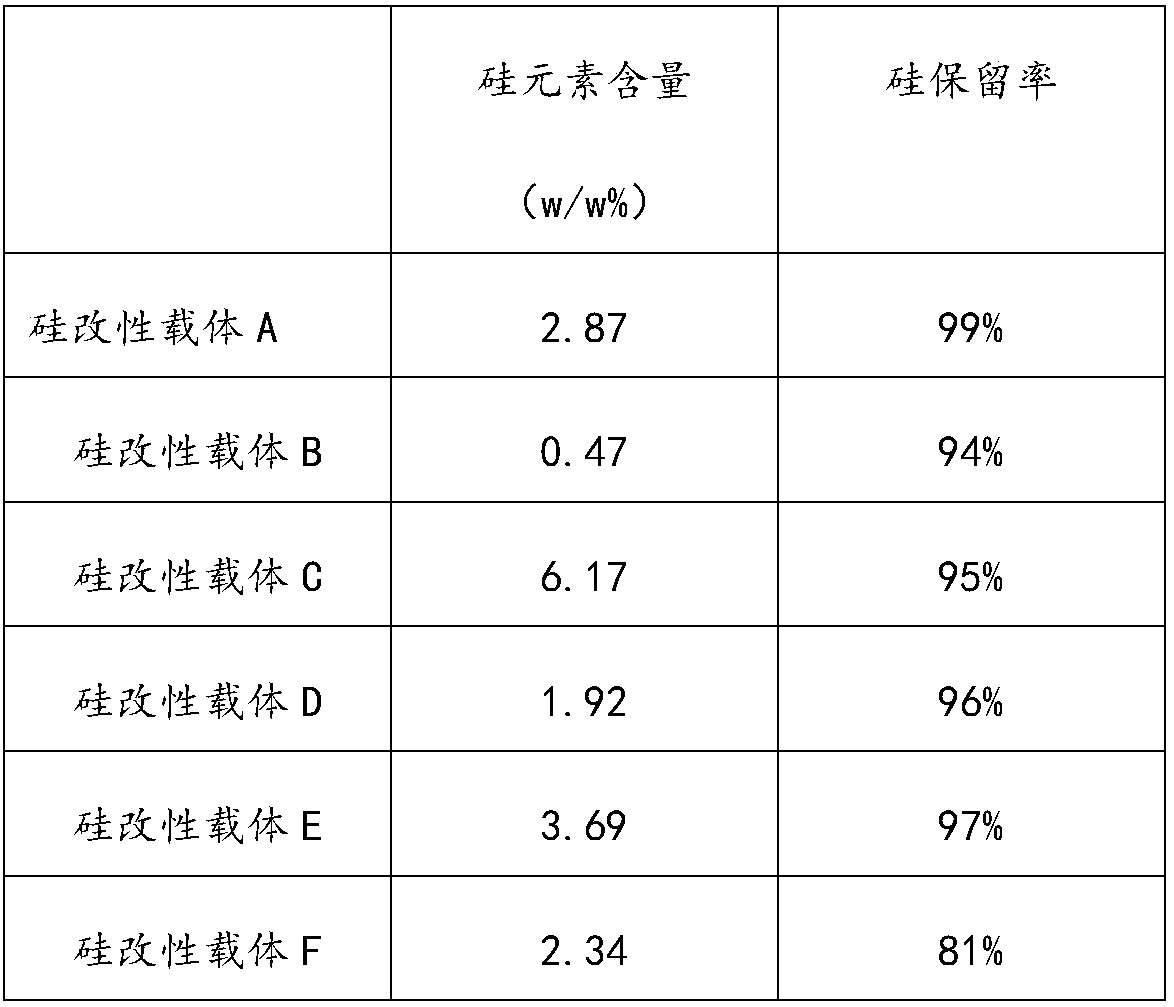

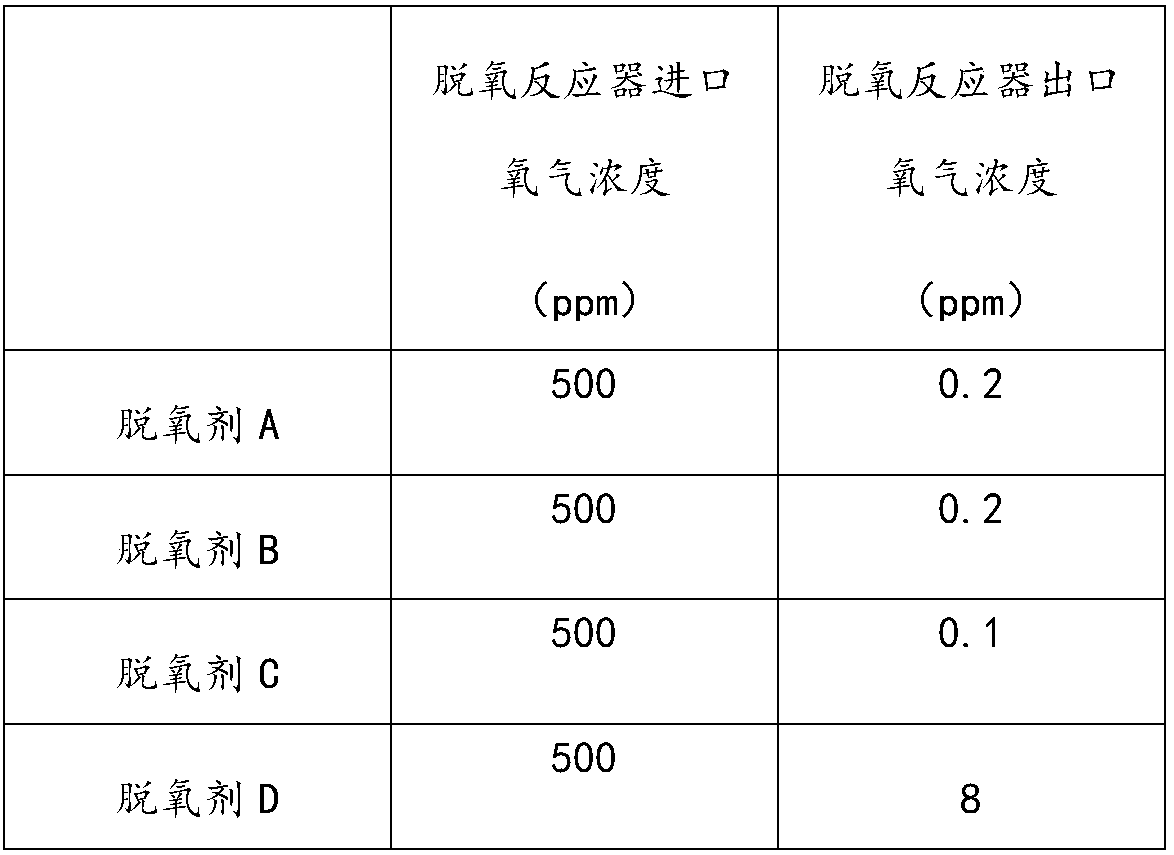

Embodiment 1

[0035] This embodiment provides a method for preparing a silicon-modified carrier, which includes the following steps:

[0036] (1) Mix absolute ethanol, deionized water and ethyl orthosilicate according to the molar ratio of 3:3:1, heat it to 50°C, and stir to obtain an alcohol solution of ethyl orthosilicate;

[0037] According to the mass of silicon contained in the tetraethyl orthosilicate alcohol solution, it is γ-Al 2 o 3 The amount of 3% by mass, the γ-Al 2 o 3 Add it into tetraethyl silicate alcohol solution, hydrolysis and polycondensation at 40°C for 1.5h, and then filter off the liquid to obtain the first prefabricated carrier, in which γ-Al 2 o 3 The particle size is 1mm;

[0038] (2) Mix xylene, methyl ethyl ketone, n-butanol and E44 epoxy resin according to the mass ratio of 2:1:1:0.2, and stir evenly to obtain an epoxy resin solution. The mass of the resin is 4% of the mass of the first prefabricated carrier, the first prefabricated carrier is added to the...

Embodiment 2

[0042] This embodiment provides a method for preparing a silicon-modified carrier, which includes the following steps:

[0043] (1) Mix absolute ethanol, deionized water and ethyl orthosilicate in a molar ratio of 5:4:1, then heat to 40°C and stir to obtain an alcohol solution of ethyl orthosilicate, and then The mass of silicon contained in ethyl acetate alcohol solution is η-Al 2 o 3 0.5% of the mass, the η-Al 2 o 3Add it to tetraethyl silicate alcohol solution, hydrolyze and polycondense for 1.5h at a temperature of 50°C, and then filter off the liquid to obtain the first prefabricated carrier, in which η-Al 2 o 3 The particle size is 3mm;

[0044] (2) Mix xylene, methyl ethyl ketone, n-butanol and E44 epoxy resin according to the mass ratio of 3:1:1:0.1, and stir evenly to obtain an epoxy resin solution. According to the epoxy resin contained in the epoxy resin solution, The mass of the resin is 2% of the mass of the first prefabricated carrier, the first prefabricat...

Embodiment 3

[0047] This embodiment provides a method for preparing a silicon-modified carrier, which includes the following steps

[0048] (1) Mix absolute ethanol, deionized water and ethyl orthosilicate in a molar ratio of 3:5:1, and stir to obtain an alcohol solution of ethyl orthosilicate, and then use the alcohol solution of ethyl orthosilicate The mass containing silicon is θ-Al 2 o 3 7% of the mass, the θ-Al 2 o 3 Add it to tetraethyl silicate alcohol solution, hydrolyze and polycondense for 1.5h, and then filter off the liquid to obtain the first prefabricated carrier, in which θ-Al 2 o 3 The particle size is 2mm;

[0049] (2) Mix xylene, methyl ethyl ketone, n-butanol and E44 epoxy resin according to the mass ratio of 3:1:1:0.4, and stir evenly to obtain an epoxy resin solution. According to the epoxy resin contained in the epoxy resin solution, The mass of the resin is 5% of the mass of the first prefabricated carrier, the first prefabricated carrier is added to the epoxy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com