A star-shaped polyacrylamide copolymer and its preparation method and drilling fluid

The technology of polyacrylamide copolymer and polyacrylamide is applied in the field of star-shaped polyacrylamide copolymer and its preparation method and drilling fluid, which can solve the problem of high viscosity of drilling fluid system, increase of cyclic pressure consumption, loss of filtration loss reduction To improve high temperature rheological properties, reduce pressure loss, and improve hydraulic parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a synthetic method for the star-shaped polyacrylamide copolymer, comprising the following synthetic steps:

[0033] Mixing pyromellitic dianhydride, azo 4-cyanopentanol, tetrahydrofuran, a nucleophilic catalyst and a dehydrating agent to perform an esterification reaction to obtain a tetrafunctional initiator;

[0034] After mixing the obtained four-functionality initiator, water, acrylamide and 2-acrylamide-2-methylpropanesulfonic acid, the copolymerization reaction is carried out under anaerobic conditions to obtain star-shaped polyacrylamide having the structure shown in formula I copolymer.

[0035] The invention mixes pyromellitic dianhydride, azo 4-cyanopentanol, tetrahydrofuran, a nucleophilic catalyst and a dehydrating agent to carry out esterification reaction to obtain a tetrafunctional initiator.

[0036] In the present invention, it is preferred to firstly mix pyromellitic dianhydride, azo 4-cyanopentanol and tetrahydrofu...

Embodiment 1

[0058] Dissolve 2.0 g of pyromellitic dianhydride and 4.0 g of azo 4-cyanopentanol in 20 mL of anhydrous tetrahydrofuran, add catalyst 4-dimethylaminopyridine (DMAP) 100 mg and dehydrating agent 1,3-dicyclohexyl Carboimide (DCC) 500 mg was reacted at room temperature for 24 hours to obtain an esterification reaction solution, which was distilled and dried to obtain a tetrafunctional initiator.

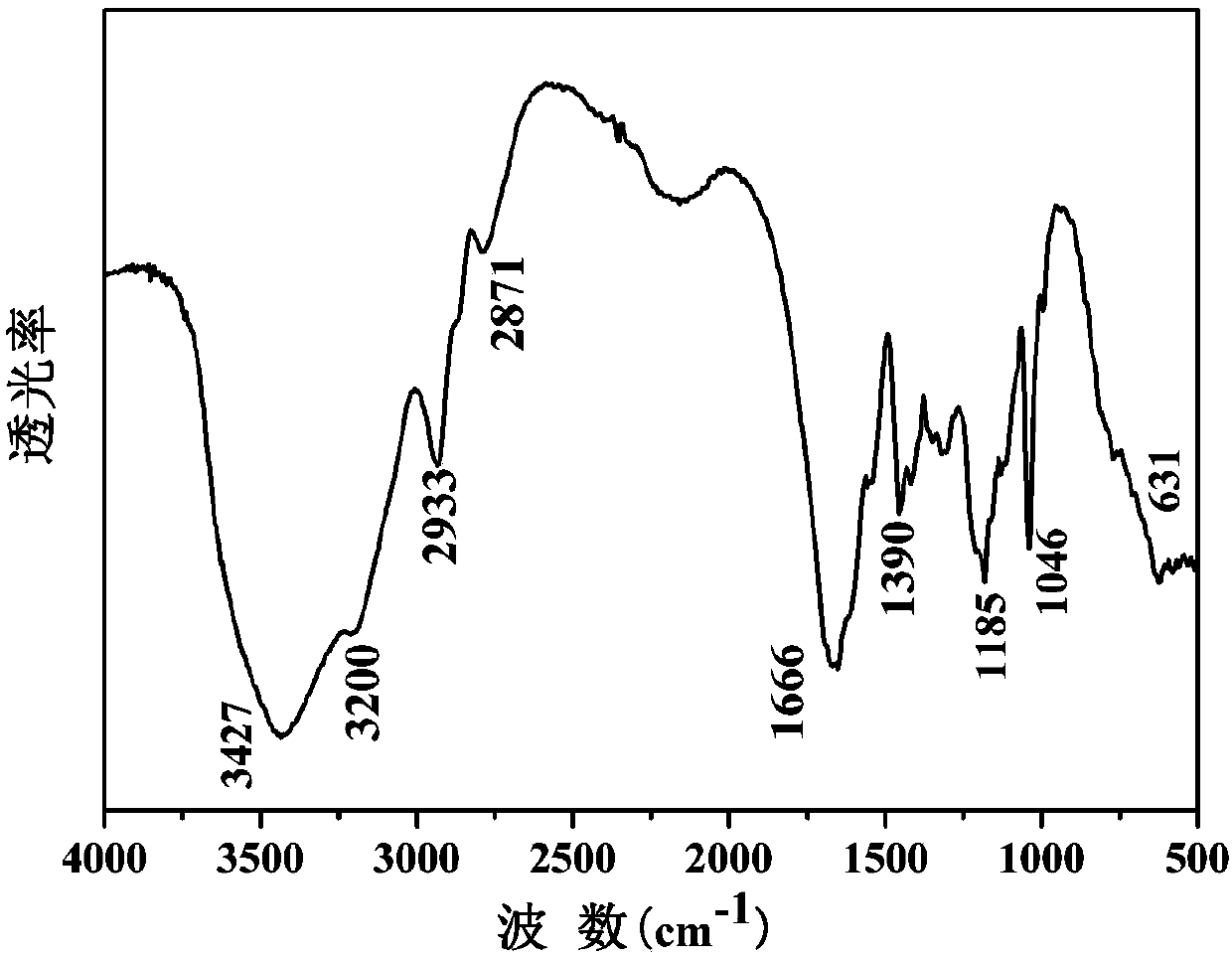

[0059] Then 30 mg of the four-functionality initiator synthesized above was dissolved in deionized water, 32 g of acrylamide monomer (AM) and 7.24 g of 2-acrylamide-2-methylpropanesulfonic acid (AMPS) were added to the system, and NaOH was used to Neutralize until the pH is 7. After the system is completely dissolved, pass argon and vacuumize for several times to remove oxygen. Then put the reaction system in a 70°C water bath. After reacting for 8 hours, add absolute ethanol to precipitate the precipitate, and then remove it by suction filtration. solvent, put it into a vacuum drying ...

Embodiment 2

[0063] Dissolve 2.0 g of pyromellitic dianhydride and 8.0 g of azo 4-cyanopentanol in 30 mL of anhydrous tetrahydrofuran, add 200 mg of catalyst 4-dimethylaminopyridine (DMAP) and 750 mg of dehydrating agent 1,3-bicyclo Hexylcarboimide (DCC) was reacted at room temperature for 24 hours, and the product was dried by distillation to obtain a tetrafunctional initiator.

[0064] Then 30 mg of the tetrafunctional initiator synthesized above was dissolved in 10 mL of deionized water, 35 g of acrylamide monomer (AM) and 8 g of 2-acrylamide-2-methylpropanesulfonic acid (AMPS) were added to the system, and NaOH was used to Neutralize until the pH is 6.5. After the system is completely dissolved, pass argon, vacuumize and replace several times to remove oxygen. Then put the reaction system in a water bath at 75°C. After reacting for 10 hours, add absolute ethanol to precipitate the precipitate, and then remove it by suction filtration. Solvent, put it into a vacuum drying oven to dry to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com