Instrumentation for level, density or interface measurement of two liquids

A technology of liquid interface and density, which is applied in the direction of liquid/fluid solid measurement, specific gravity measurement, measuring device, etc., can solve the problems of high pressure resistance of the float, increase the quality of the float, and discontinuous signal, so as to improve the measurement accuracy and sensitivity, Effect of overcoming the influence of measurement accuracy and increasing the temperature application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

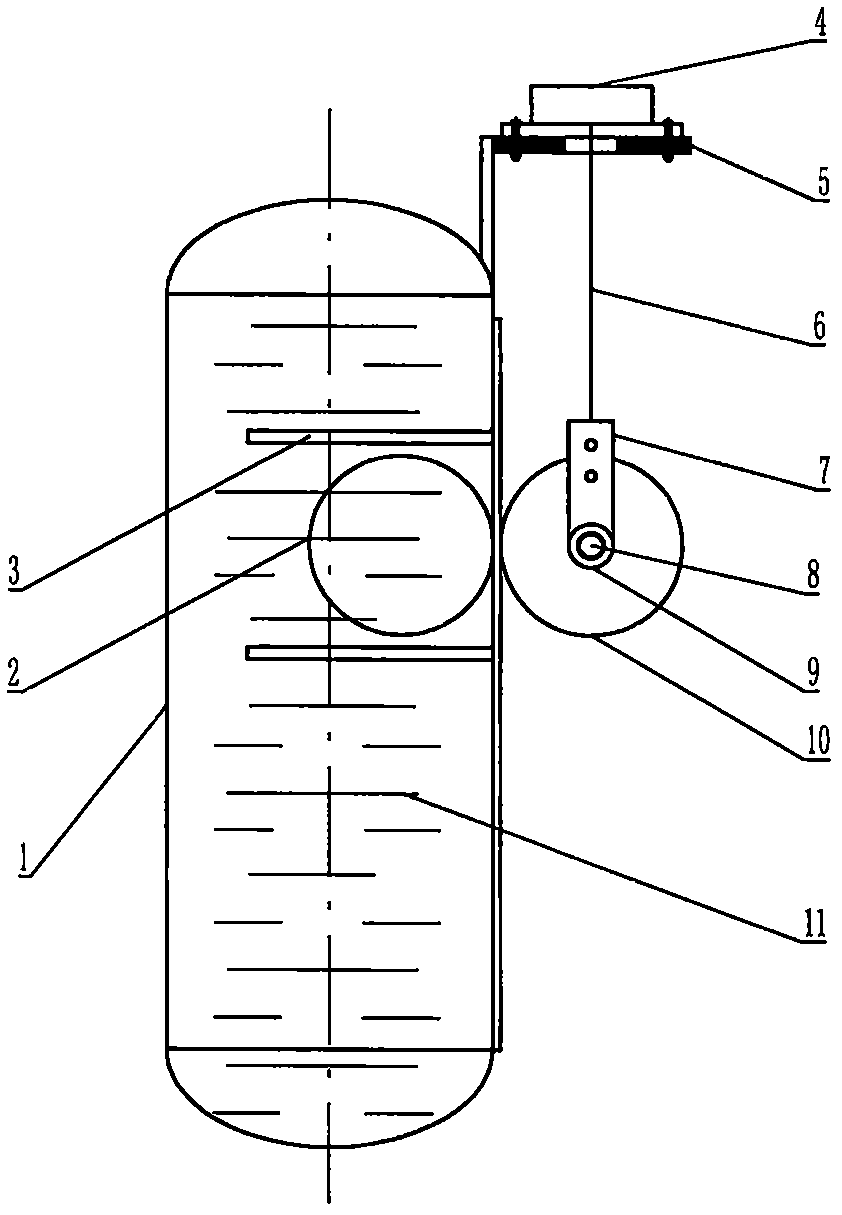

[0095] An instrument for liquid level, density, or interface measurement between two liquids, such as figure 1 and image 3 As shown, it includes a container of non-ferromagnetic material containing liquid 11 or a sinker 2 of ferromagnetic material inside the sinker chamber 1. The sinker 2 of ferromagnetic material is a rotating body, and the axis of the sinker 2 is parallel to Ground; there is a disc or cylindrical magnetic steel 10 magnetically coupled with the sinker 2 of ferromagnetic material on the outside of the non-ferromagnetic material container or sinker chamber 1, and the radial outer portion of the disc or cylindrical magnetic steel 10 is The surface is attached to the outer wall of the container or the sinker chamber 1, and the axis of the disc or cylindrical magnetic steel 10 is parallel to the ground; The surfaces are in rolling contact up and down, and the magnetic poles are located in the axial direction of the magnetic steel 10 .

[0096] At the same time,...

Embodiment 2

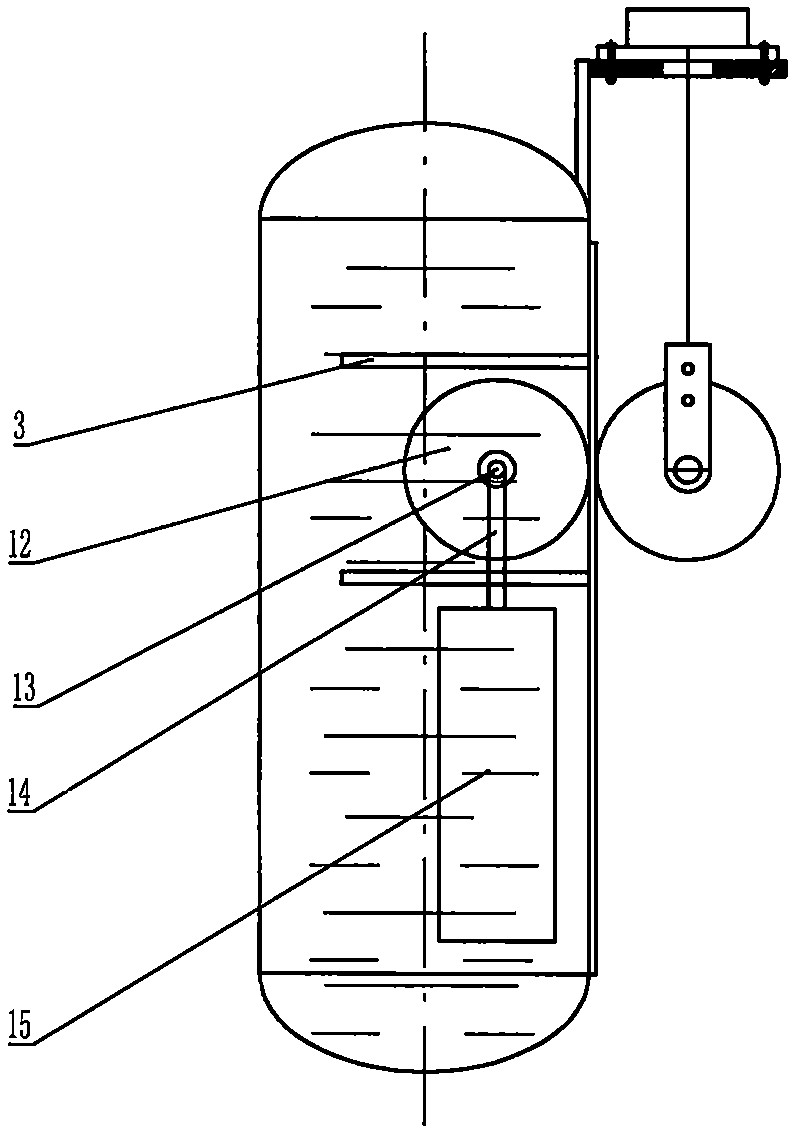

[0106] In order to realize the continuous measurement of the liquid level or measure the liquid level, density or the boundary of two liquids in a larger range, such as figure 2 and image 3 Shown, differ from embodiment 1 in that:

[0107] The sinker is an assembly, which includes a rod-shaped sinker 15 and a roller 12 above it, the two are connected to each other by two connecting rods 14 parallel to each other and the central axis 13 of the roller, and the connecting rod 14 The lower end of the connecting rod 14 is connected to the sinking cylinder 15, and the upper end of the connecting rod 14 is hinged with the central axis 13 of the roller; or, the roller 12 is clearance fit with the central axis 13;

[0108] The roller 12 is made of ferromagnetic material, and its outer diameter is larger than the outer diameter of the sinking cylinder 15;

[0109] The axis of the roller 12 is perpendicular to the axis of the rod-shaped sink 15, wherein the axis of the rod-shaped sin...

Embodiment 3

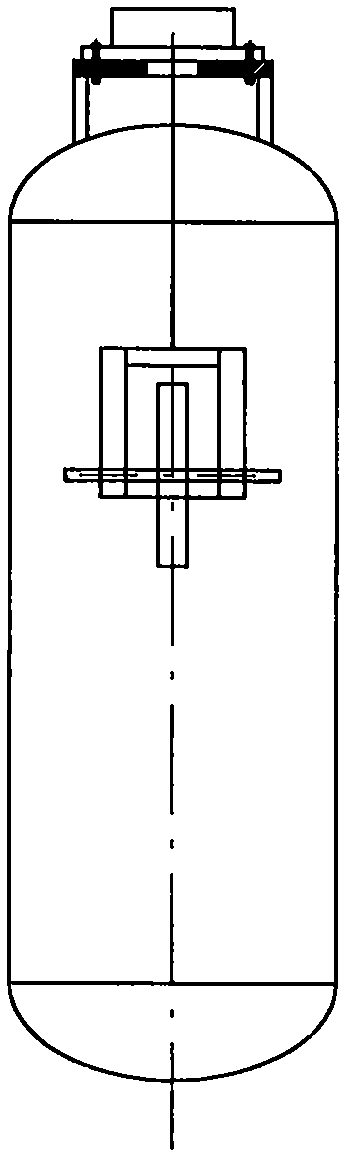

[0114] In order to reduce the influence of demagnetization when the magnetic steel contacts the cylinder at high temperature, it is necessary to avoid direct contact between the magnetic steel and the cylinder. The instrument for measuring the liquid level, density or two liquid interfaces, such as Figure 4 and Figure 5 As shown, on the basis of embodiment 1 or embodiment 2, the difference from the first two embodiments mainly lies in:

[0115] The two ends of the central axis 8 of the magnetic steel are supported on the two arms of the inverted concave frame 7 through bearings 9 and extend out a certain length respectively;

[0116] It also includes two guide rails 16, the guide rails 16 are perpendicular to the ground, installed outside the container or sinker chamber 1, between the container or sinker chamber 1 and the central axis 8 of the magnetic steel, and between them The corresponding surfaces are respectively tangent to the radial surfaces of the two ends where th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com