Method of using ionic liquid solvent system to dissolve fermented mushroom dregs to prepare polymers

An ionic liquid solvent and ionic liquid technology, applied in the preparation method of peptides, chemical instruments and methods, organic chemistry, etc., can solve the problems of low realization value and low utilization rate of organic matter in fermentation slag, and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

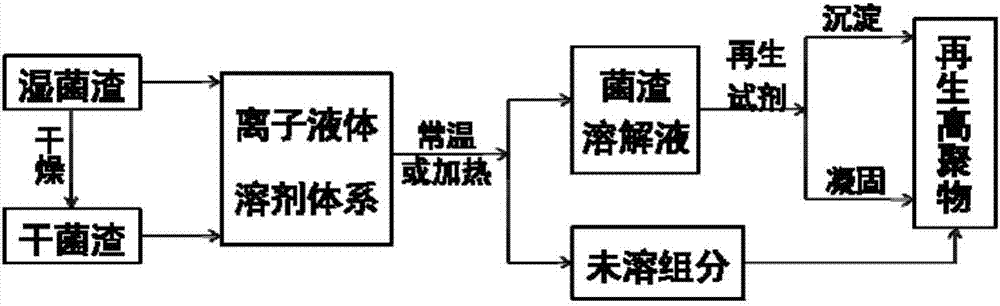

Method used

Image

Examples

Embodiment 1

[0070] A method for preparing high polymers by dissolving fermentation scum in an ionic liquid solvent system, comprising the steps of:

[0071] (1) Take 20 g of wet penicillin fermented bacteria residue, mix it with a single ionic liquid system (1-butyl-3-methylimidazolium chloride salt) at a mass ratio of 1:0.01, and dissolve it at 10°C for 600 minutes to obtain a solution of bacteria residue and undissolved components;

[0072] (2) The anhydrous salt solution and the bacterial residue solution are mixed evenly at a volume ratio of 0.1:1, so that the solute is precipitated to obtain a regenerated polymer; the undissolved components are washed in the order of n-butanol-water-n-butanol to remove residual ions Liquid, after drying at 10°C, a uniform white polymer powder is obtained.

[0073] The extraction rate of the high polymer was 47.9%.

Embodiment 2

[0075] A method for preparing high polymers by dissolving fermentation scum in an ionic liquid solvent system, comprising the steps of:

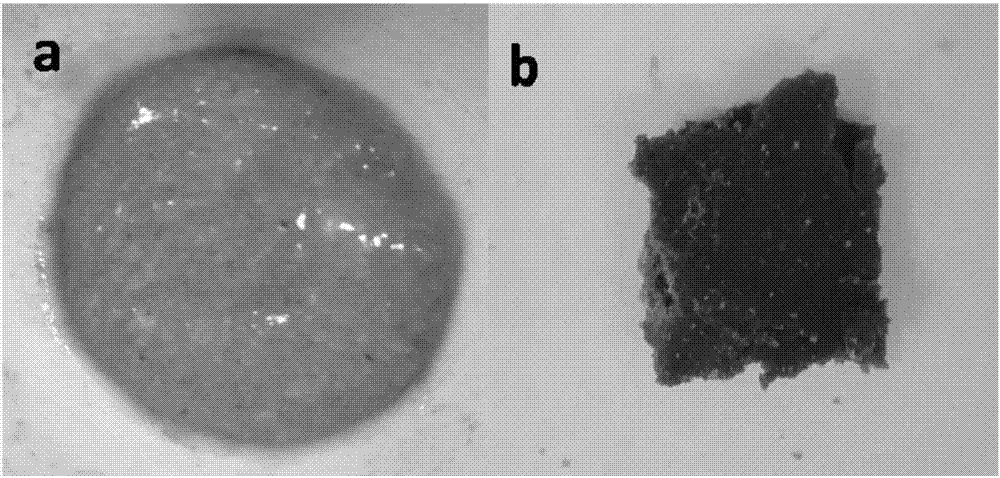

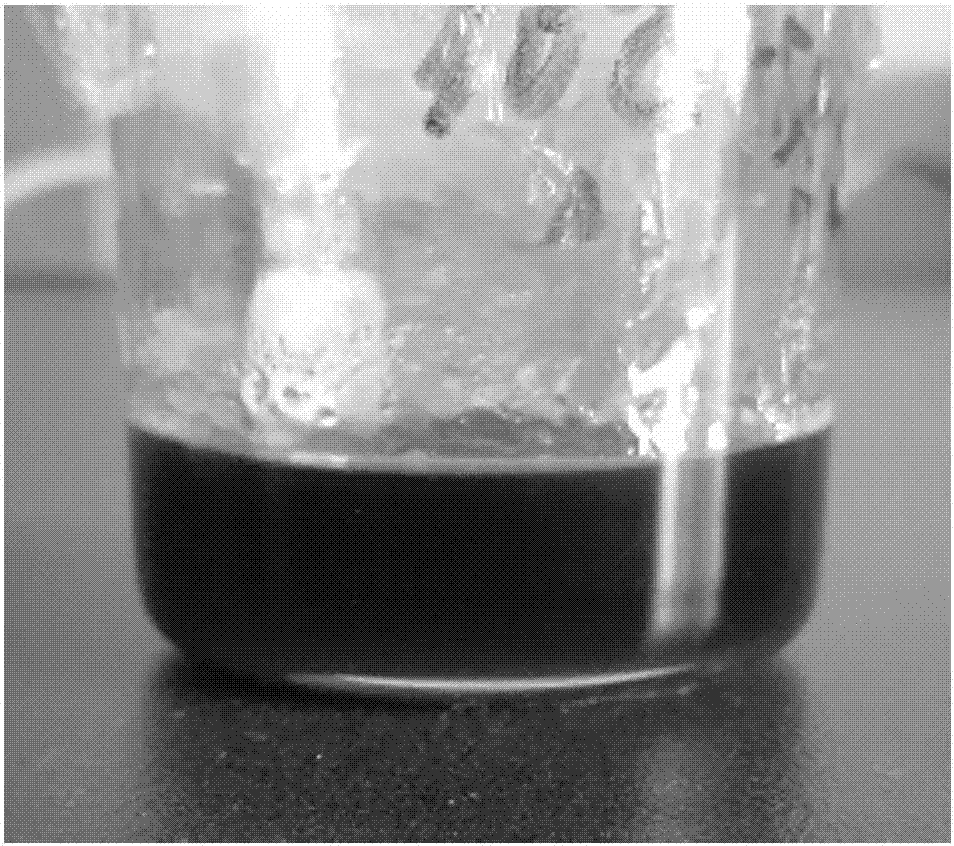

[0076] (1) Get wet penicillin fermentation slag (such as figure 2 Shown in a) 20g, after washing with 20mL municipal tap water, suction filtration, the bacterial residue that suction filtration obtains (such as figure 2 Shown in b) dried at 80°C to constant weight; the dried bacteria residue was mixed with a single ionic liquid system (1-butyl-3-methylimidazole acetate) at a mass ratio of 1:10, and dissolved at 90°C 720min to get the bacterium residue solution (such as image 3 shown);

[0077] (2) Methanol, water mixed solution and bacterial residue solution are mixed evenly at a volume ratio of 1:1 to precipitate the solute and obtain a regenerated polymer (such as Figure 4 shown).

[0078] The extraction rate of the high polymer was 48.0%.

Embodiment 3

[0080] A method for preparing high polymers by dissolving fermentation scum in an ionic liquid solvent system, comprising the steps of:

[0081] (1) Take 20 g of wet penicillin fermented bacteria residue, wash with 20 mL of anhydrous salt water and then suction filter, and dry the bacteria residue obtained by suction filtration to constant weight at 160 ° C; dry bacteria residue and single ionic liquid system (choline acetate) Mix at a mass ratio of 1:0.5, and dissolve at 90°C for 600 minutes to obtain a solution of fungus residue;

[0082] (2) Methanol and bacterial residue solution are mixed evenly at a volume ratio of 2:1 to precipitate the solute to obtain a regenerated polymer; the undissolved components are washed in the order of n-butanol-water-n-butanol to remove residual ionic liquid , and dried at 30°C to obtain a white polymer powder (such as Figure 6 shown).

[0083] The extraction rate of the polymer was 48.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com