Anti-radiation function board and preparation method thereof

A functional board and anti-radiation technology, which is applied in the field of building boards, can solve the problems of easy fracture and poor impact resistance of boards, and achieve good radiation protection, reduce external force cracking, and increase impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

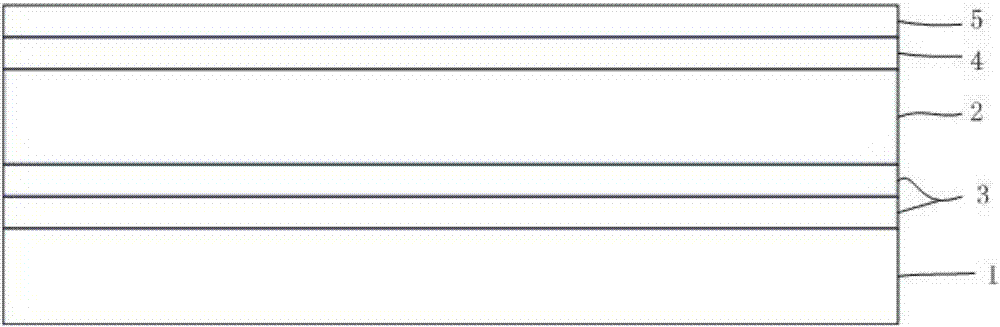

[0032] Embodiment one: figure 1 As shown, a radiation-proof functional board includes a first radiation-proof layer 1 and a second radiation-proof layer 2, and a first grid cloth is also arranged between the first radiation-proof layer 1 and the second radiation-proof layer 2 Layer 3, the first radiation protection layer 1 and the second radiation protection layer 2 are composed of sulphoaluminate cement, barite sand, barite powder, barium sulfate, quartz sand and impurities, and the first grid Cloth layer 3 is glass fiber mesh cloth.

[0033] The fineness of the barite powder is 210 mesh, the fineness of the barite sand is 10 mesh, and the content of the barium sulfate is 85%. In turn, the impact resistance and molding time of the anti-radiation functional board are significantly improved.

[0034] The first mesh cloth layer 3 is a double-layer alkali-resistant mesh cloth. The flexural strength of the anti-radiation functional board is greatly improved.

[0035] The singl...

Embodiment 2

[0045] Embodiment two: figure 1 As shown, a radiation-proof functional board includes a first radiation-proof layer 1 and a second radiation-proof layer 2, and a first grid cloth is also arranged between the first radiation-proof layer 1 and the second radiation-proof layer 2 Layer 3, the first radiation protection layer 1 and the second radiation protection layer 2 are composed of sulphoaluminate cement, barite sand, barite powder, barium sulfate, quartz sand and impurities, and the first grid Cloth layer 3 is glass fiber mesh cloth.

[0046] The fineness of the barite powder is 300 mesh, the fineness of the barite sand is 60 mesh, and the content of the barium sulfate is 90%. In turn, the impact resistance and molding time of the anti-radiation functional board are significantly improved.

[0047] The surface of the second anti-radiation layer 2 is provided with a second mesh cloth layer 4, and the second mesh cloth layer 4 is a glass fiber mesh cloth. The flexural streng...

Embodiment 3

[0060] Embodiment three: figure 1 As shown, a radiation-proof functional board includes a first radiation-proof layer 1 and a second radiation-proof layer 2, and a first grid cloth is also arranged between the first radiation-proof layer 1 and the second radiation-proof layer 2 Layer 3, the first radiation protection layer 1 and the second radiation protection layer 2 are composed of sulphoaluminate cement, barite sand, barite powder, barium sulfate, quartz sand and impurities, and the first grid Cloth layer 3 is glass fiber mesh cloth.

[0061] The fineness of the barite powder is 350 mesh, the fineness of the barite sand is 50 mesh, and the content of the barium sulfate is about 93%. In turn, the impact resistance and molding time of the anti-radiation functional board are significantly improved.

[0062] The surface of the second anti-radiation layer 2 is provided with a second mesh cloth layer 4, and the second mesh cloth layer 4 is a glass fiber mesh cloth.

[0063] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com