Fe/Co-Nx/TiO2 photocatalyst and preparation method and application thereof

A photocatalyst, co-nx technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as photocatalytic performance that few people study, and achieve easy-to-obtain raw materials and high degradation Ability, low toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

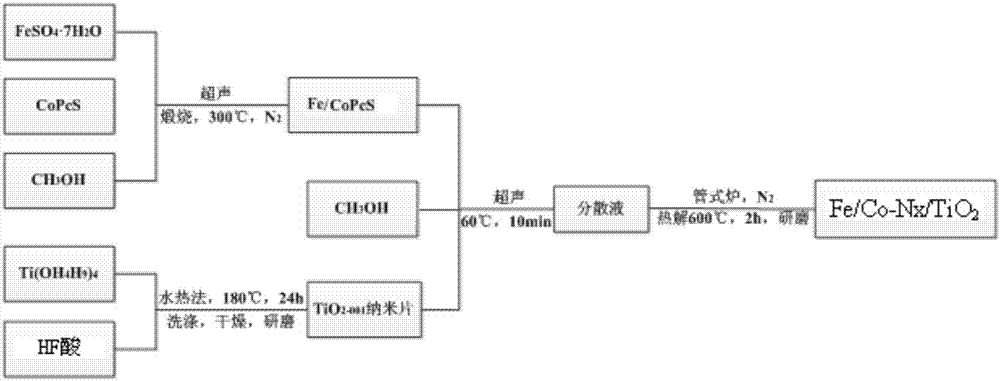

[0032] Fe / Co-Nx / TiO of the present invention 2 The preparation method of photocatalyst specifically comprises the following steps:

[0033] Step 1, preparation of Fe / Co-Nx nanoparticles: Weigh 0.4g ferrous sulfate heptahydrate and 0.6g sulfonated cobalt phthalocyanine and place it in 4ml methanol for ultrasonication for 10min, place the resulting mixture in a tube furnace, and place the mixture under N 2 Calcined for 2 hours under the protection of the atmosphere, the calcined temperature is 300 ℃, and Fe / CoPcS is obtained after grinding;

[0034] Step 2: Take 25mL of butyl titanate, 5mL of hydrofluoric acid and 5mL of deionized water respectively, place them in a polytetrafluoroethylene container, mix and stir evenly, and then react in the reactor at 180°C for 24h; centrifuge the obtained product Finally, wash with deionized water and absolute ethanol three times, dry, and grind to obtain TiO 2 (001) nanosheets;

[0035] Step 3, weigh 50mgFe / CoPcS and 200mgTiO 2 (001) Nan...

Embodiment 2

[0037] Fe / Co-Nx / TiO of the present invention 2 The preparation method of photocatalyst specifically comprises the following steps:

[0038] Step 1, preparation of Fe / Co-Nx nanoparticles: Weigh 0.4g ferrous sulfate heptahydrate and 0.6g sulfonated cobalt phthalocyanine and place it in 4ml methanol for ultrasonication for 10min, place the resulting mixture in a tube furnace, and place the mixture under N 2 Calcined for 2 hours under the protection of the atmosphere, the calcined temperature is 300 ℃, and Fe / CoPcS is obtained after grinding;

[0039] Step 2: Take 25mL of butyl titanate, 5mL of hydrofluoric acid and 5mL of deionized water respectively, place them in a polytetrafluoroethylene container, mix and stir evenly, and then react in the reactor at 170°C for 20h; centrifuge the obtained product Finally, wash with deionized water and absolute ethanol three times, dry, and grind to obtain TiO 2 (001) nanosheets;

[0040] Step 3, weigh 50mgFe / CoPcS and 200mgTiO 2 (001) Nanos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com