Method for making corn steamed sponge cakes through microwaves

A corn cake and microwave technology, which is applied in the field of food processing, can solve the problems of easy aging and drying of corn cake, rough taste of corn cake, poor uniformity of pores, etc., and achieve the effect of improving rough taste, delicate taste and improving viscoelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

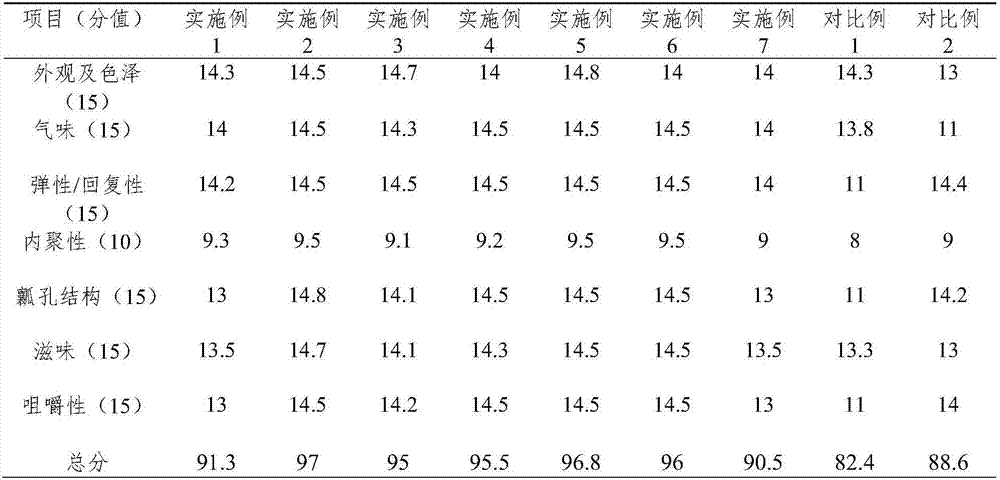

Embodiment 1

[0039] A method for preparing corn cakes by microwave, comprising the steps of:

[0040] 1. Corn flour refining treatment: ordinary corn flour is used as raw material, and ultrafine grinding is carried out at room temperature, so that the diameter of corn flour particles is 150-80 μm, which is corn ultrafine powder. The pulverization method can be airflow ultrafine pulverization, mechanical shear ultrafine pulverization or ultrahigh pressure microjet ultrafine pulverization.

[0041] 2. Recipe for gluten-free microwave corn cake: 30 parts of corn superfine powder, 10 parts of corn pre-fermented powder, 10 parts of corn pre-gelatinized powder, and 1 part of yeast.

[0042] 3. Corn pre-fermented powder uses corn superfine powder as raw material, adds 2 times the volume of water, adds 0.5% lactic acid bacteria, ferments at 36°C for 12 hours, and dries the powder after fermentation (low temperature drying or freeze-drying at no more than 50°C) to prepare corn prebaked powder.

...

Embodiment 2

[0049] A method for preparing corn cakes by microwave, comprising the steps of:

[0050] 1. Corn flour refining treatment: ordinary corn flour is used as raw material, and ultrafine grinding is carried out at room temperature, so that the diameter of corn flour particles is 80 μm, which is corn ultrafine powder. The pulverization method can be airflow ultrafine pulverization, mechanical shear ultrafine pulverization or ultrahigh pressure microjet ultrafine pulverization.

[0051] 2. Recipe of gluten-free microwave corn cake: 50 parts of corn superfine powder, 30 parts of corn pre-fermented powder, 20 parts of corn pre-gelatinized powder, 2.5 parts of xanthan gum, 15 parts of pumpkin powder, and 2 parts of yeast.

[0052] 3. Corn pre-fermented powder uses corn superfine powder as raw material, adds 2 times (w / v) water, adds 2% lactic acid bacteria, ferments at 40°C for 36h, and the powder after fermentation is dried (low temperature drying or freeze-drying at no more than 50°C)...

Embodiment 3

[0059] A method for preparing corn cakes by microwave, comprising the steps of:

[0060] 1. Corn flour refining treatment: ordinary corn flour is used as raw material, and ultrafine grinding is carried out at room temperature, so that the diameter of corn flour particles is 90 μm, which is corn ultrafine powder. The pulverization method can be airflow ultrafine pulverization, mechanical shear ultrafine pulverization or ultrahigh pressure microjet ultrafine pulverization.

[0061] 2. Gluten-free microwave corn cake recipe: 35 parts of corn superfine powder, 15 parts of corn pre-fermented powder, 15 parts of corn pre-gelatinized powder, 2 parts of waxy corn starch, 0.5 part of carrageenan, 5 parts of carrot powder, 1.5 parts of yeast share.

[0062] 3. Corn pre-fermented powder uses corn superfine powder as raw material, adds 2 times (w / v) water, adds 0.1% lactic acid bacteria, ferments at 37°C for 15 hours, and then dries the powder after fermentation (low temperature drying o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com