Sealing device

A technology of sealing device and sealing ring, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of unfavorable unit economic optimization, short service life, etc., and achieve the purpose of increasing service life, reducing energy loss, and improving economic operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

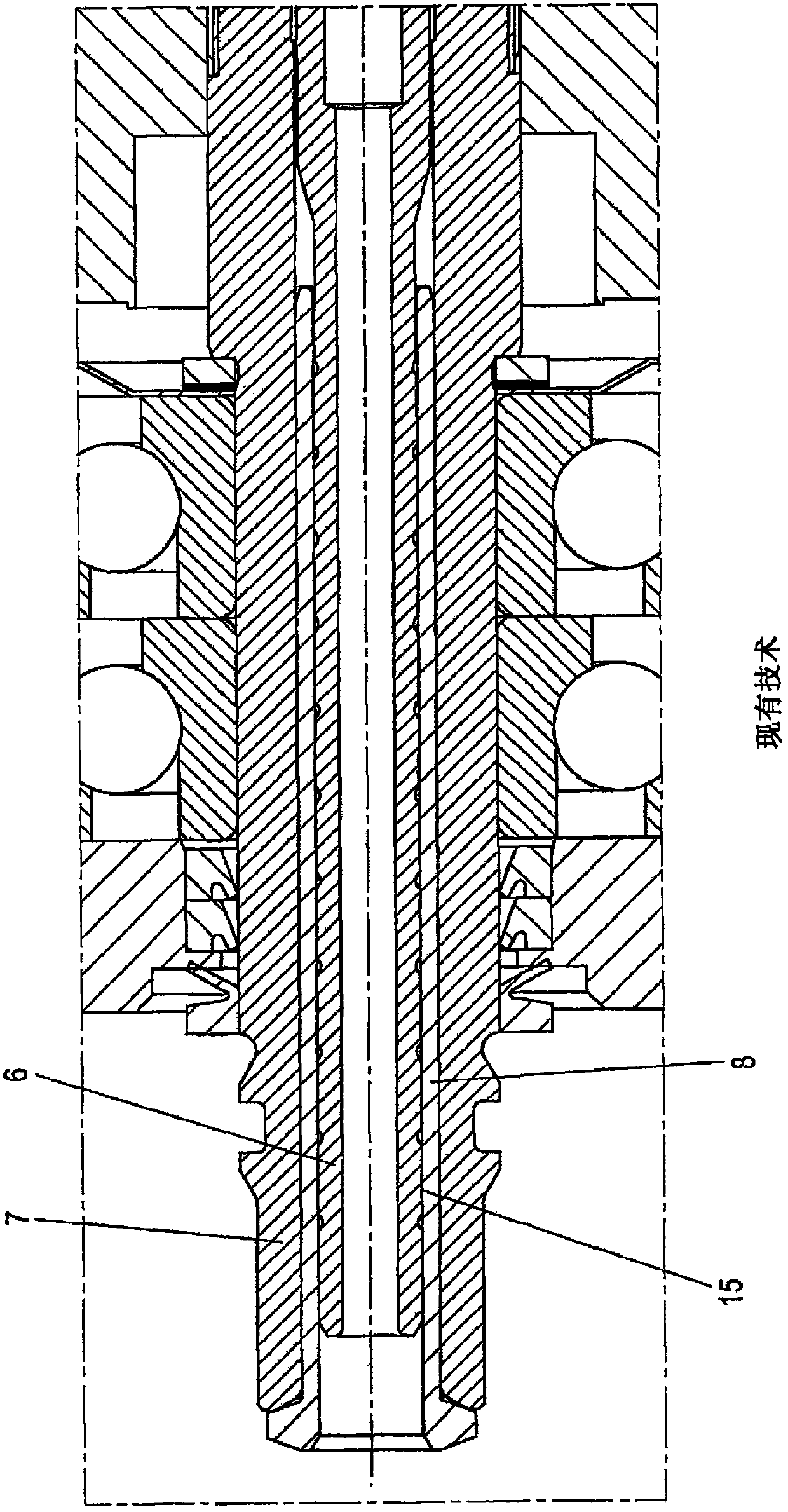

[0028] figure 1 shows a sealing device according to the prior art with an inner body 6 designed as a sleeve, an intermediate bush 8 which surrounds the inner body 6 and is mounted in an outer sleeve 7 by forming a gap seal, Therein an annular gap 15 is formed between the inner body 6 and the intermediate bushing 8 . With this design, the pressure of the fluid to be sealed causes the sleeve to widen, resulting in increased leakage.

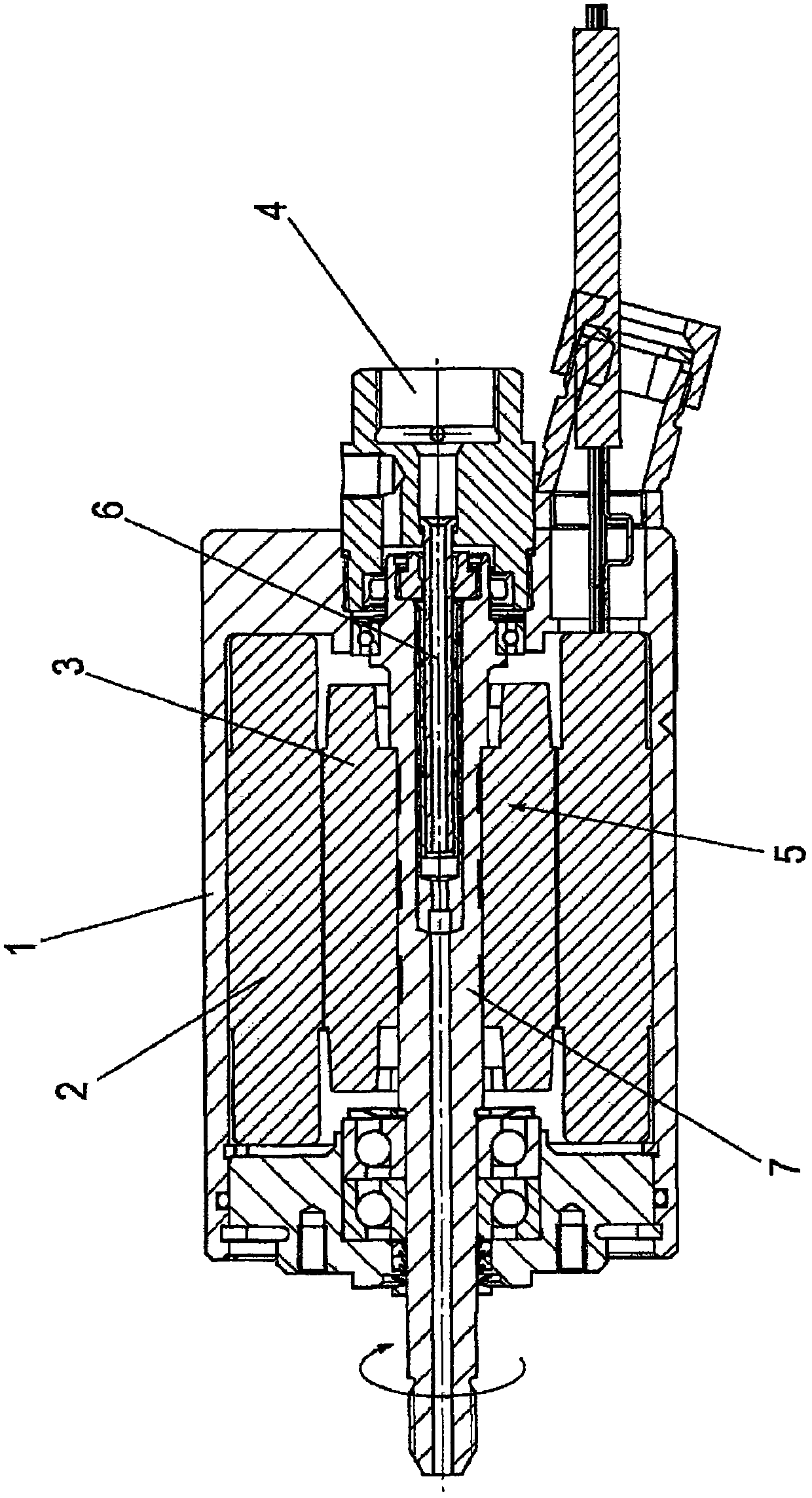

[0029] figure 2 An electric rotary drive for a hydraulic tool is shown having a housing 1, a stator 2 mounted in a rotationally fixed manner in the housing 1, and a rotor 3 in which an outer sleeve 7 is held in a rotationally fixed manner, Fluid at high pressure (>2000 bar) can be fed therethrough via the fluid connection 4 .

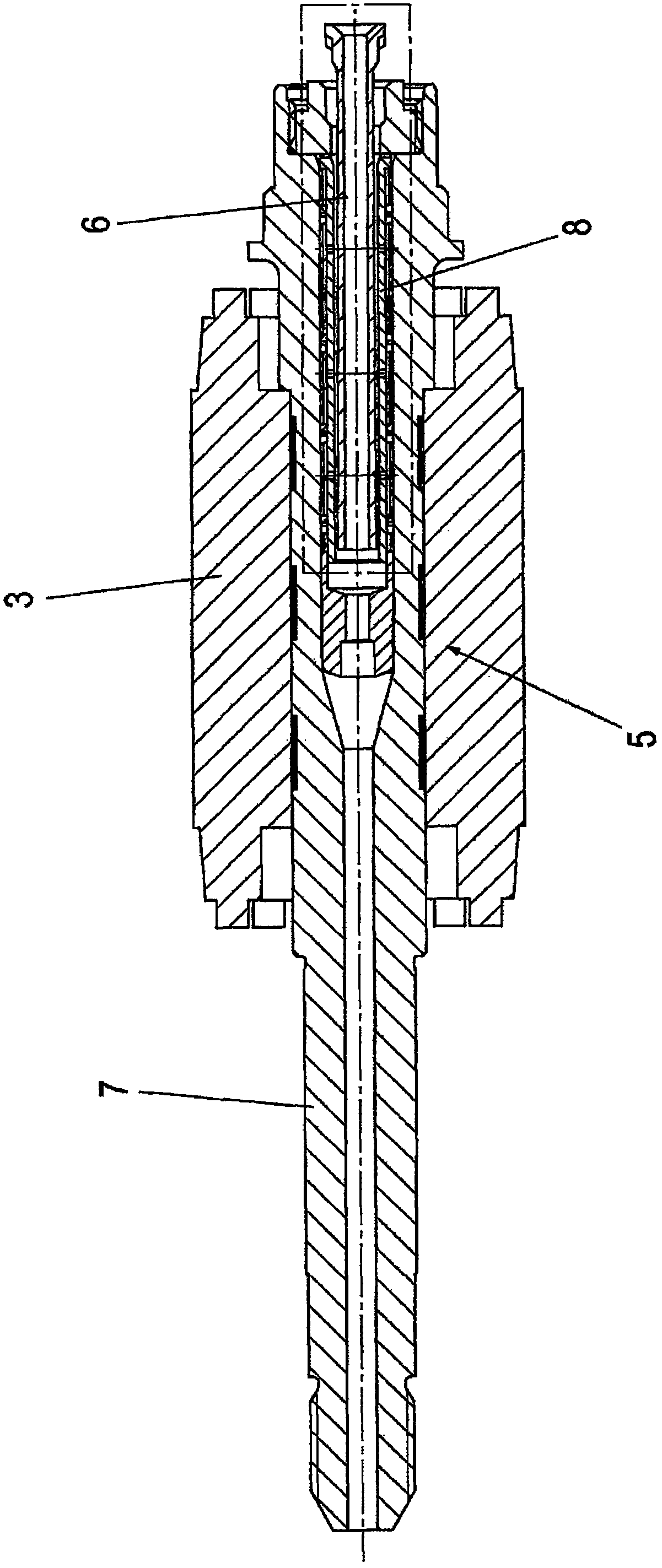

[0030] The outer sleeve 7 is part of the sealing device 5 according to the invention, the outer sleeve 7 can be placed in Figure 3-6 It can be seen more clearly in the enlarged view of .

[0031] The inner body 6 is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com