Distributed feedback semiconductor laser device and photo integrated transmitting chip module

A distributed feedback, semiconductor technology, applied in the field of optoelectronics, which can solve problems such as the decline of chip yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

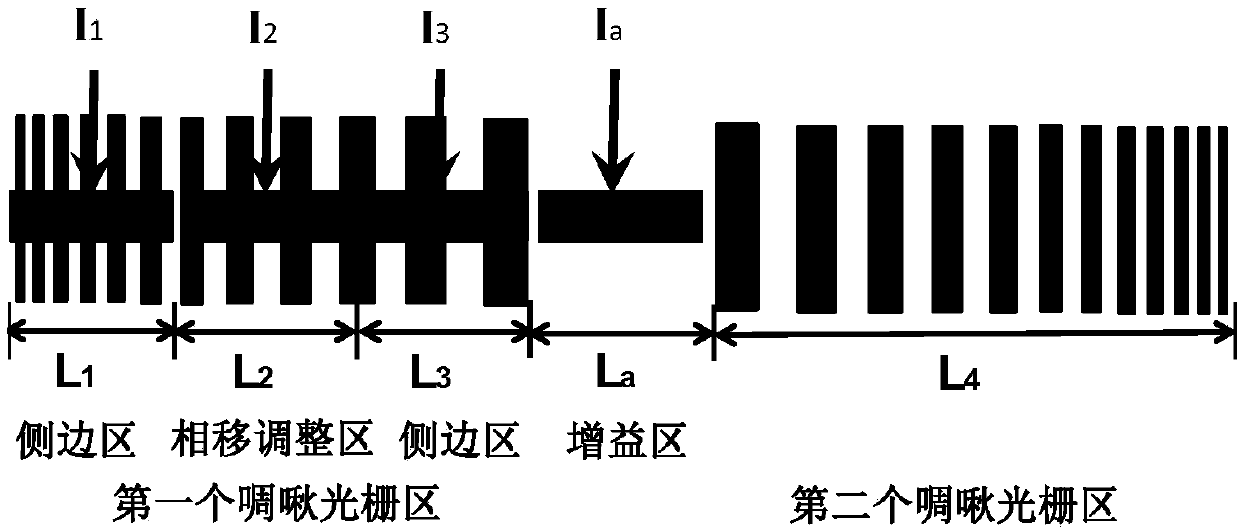

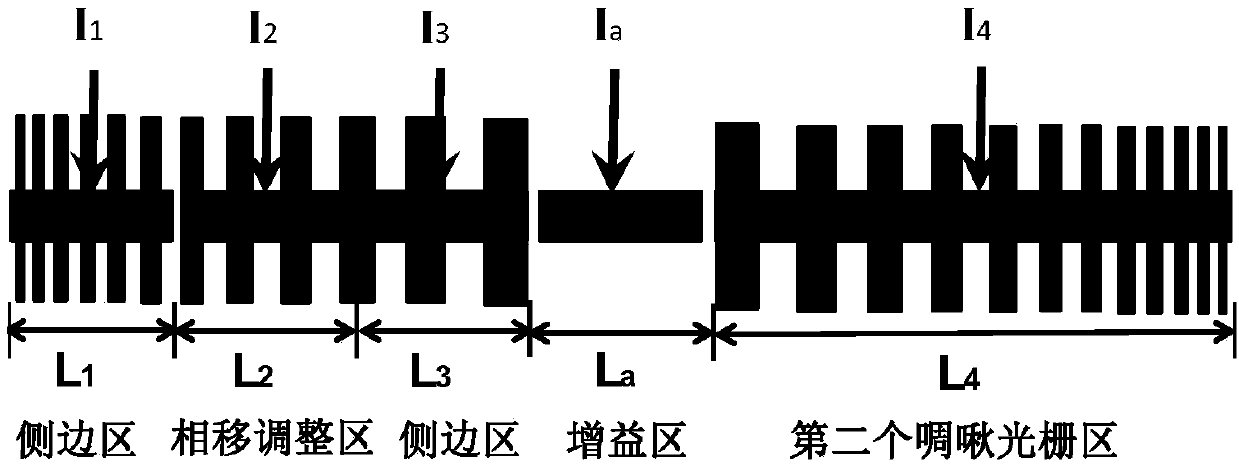

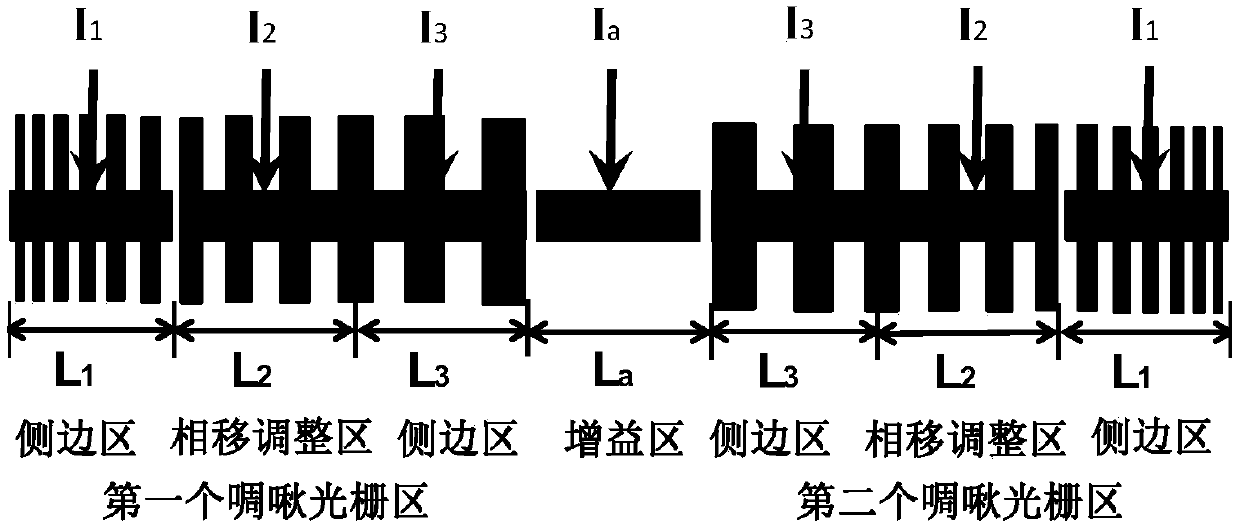

[0032] This embodiment provides a distributed feedback semiconductor laser device, which is formed by connecting two chirped gratings in series through a gain region without a grating, or by connecting two sampling gratings with a sampling period chirped in series through a gain region without a grating ; The electrode of the first chirped grating is composed of three electrodes electrically isolated from each other, the corresponding part of the middle electrode of the grating is the phase shift adjustment area, and the corresponding part of the electrodes on both sides of the grating is the side area; the second chirped grating The corresponding part of the grating is a passive area without gain (such as figure 1 shown), or by a (such as figure 2 shown) or multiple (such as image 3 shown) electrode-controlled active region. The structure of the active region of the first chirped grating of the distributed feedback semiconductor laser of the present invention is as follow...

Embodiment 2

[0041] This embodiment provides a monolithic integrated array of distributed feedback semiconductor lasers, which is composed of the distributed feedback semiconductor laser device described in Embodiment 1.

[0042] This embodiment also provides a photonic integrated emission chip module (such as Figure 5 shown), the module consists of a laser monitor array, the above-mentioned distributed feedback semiconductor laser monolithic integrated array, a modulator array, a power equalizer array and a multiplexer, which are sequentially grown and integrated into formed on the same epitaxial wafer.

Embodiment 3

[0044] This embodiment adopts a manufacturing method of a distributed feedback semiconductor laser and an array thereof, the steps of which are as follows:

[0045] (1) Epitaxial n-type InP buffer layer, 100nm thick undoped lattice-matched InGaAsP lower confinement layer, strained InGaAsP multiple quantum wells and 100nm thick p-type lattice-matched InGaAsP upper confinement layer on n-type InP substrate material layer;

[0046] (2) The production method of the grating:

[0047] ①The manufacturing method of the linear chirped sampling grating, using the method of double-beam holographic interference to expose through the sampling photoresist, transfer the chirped sampling grating pattern to the photoresist on the upper confinement layer, and then perform material etching, A required chirped sampling grating structure is formed on the upper part of the upper confinement layer.

[0048] ②The manufacturing method of the linear chirped grating, using the method of high-precision...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com