Wire rod excellent in drawing processability and method for producing the same

A technology of stretching processability and wire rod, applied in the field of wire rod and its manufacturing, can solve the problems of stretching processability that have not been clearly disclosed, and achieve the effect of excellent stretching processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, preferred embodiments of the present invention will be described. However, the embodiments of the present invention can be modified in various ways, and the scope of the present invention is not limited to the embodiments described below. In addition, the embodiments of the present invention are provided to more completely explain the present invention to those skilled in the art to which the present invention pertains.

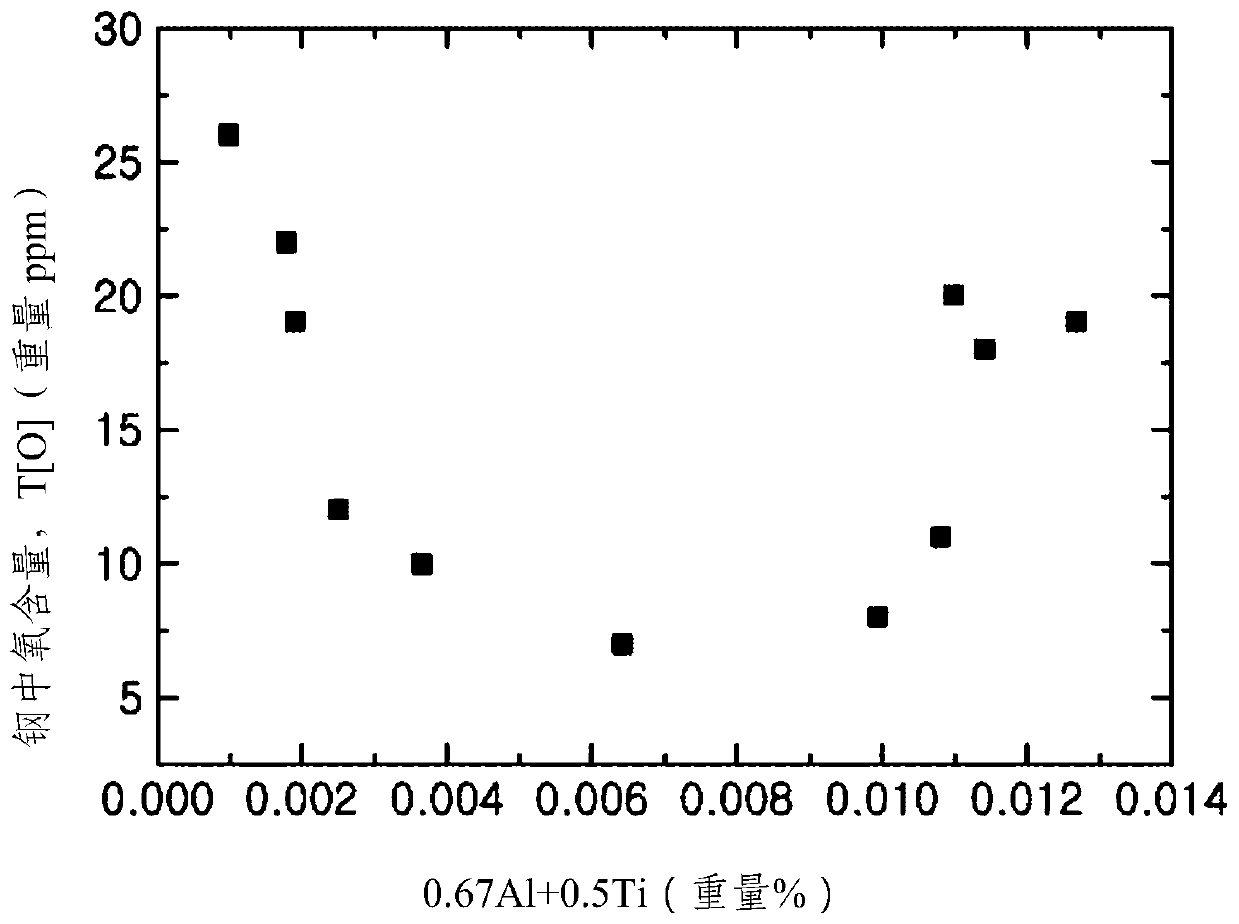

[0030] The inventors understood that suppression of inclusions is required to improve drawing workability, but the effect of the number or size of inclusions on drawing workability is not clearly disclosed, and the optimal alloy composition for ensuring cleanliness and drawing workability It has not been clearly disclosed either, and therefore intensive research has been conducted to solve the above-mentioned problems.

[0031] Finally, it was confirmed that the Al existing in the spring steel 2 o 3 , TiN and other hard inclusions are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com