A method for extracting divalent cobalt ions by p204

A technology of divalent cobalt ions and cobalt ions, applied in the direction of improving process efficiency, etc., can solve the problems of low extraction rate of divalent cobalt ions, and achieve the effects of efficient and rapid extraction, cost reduction, and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

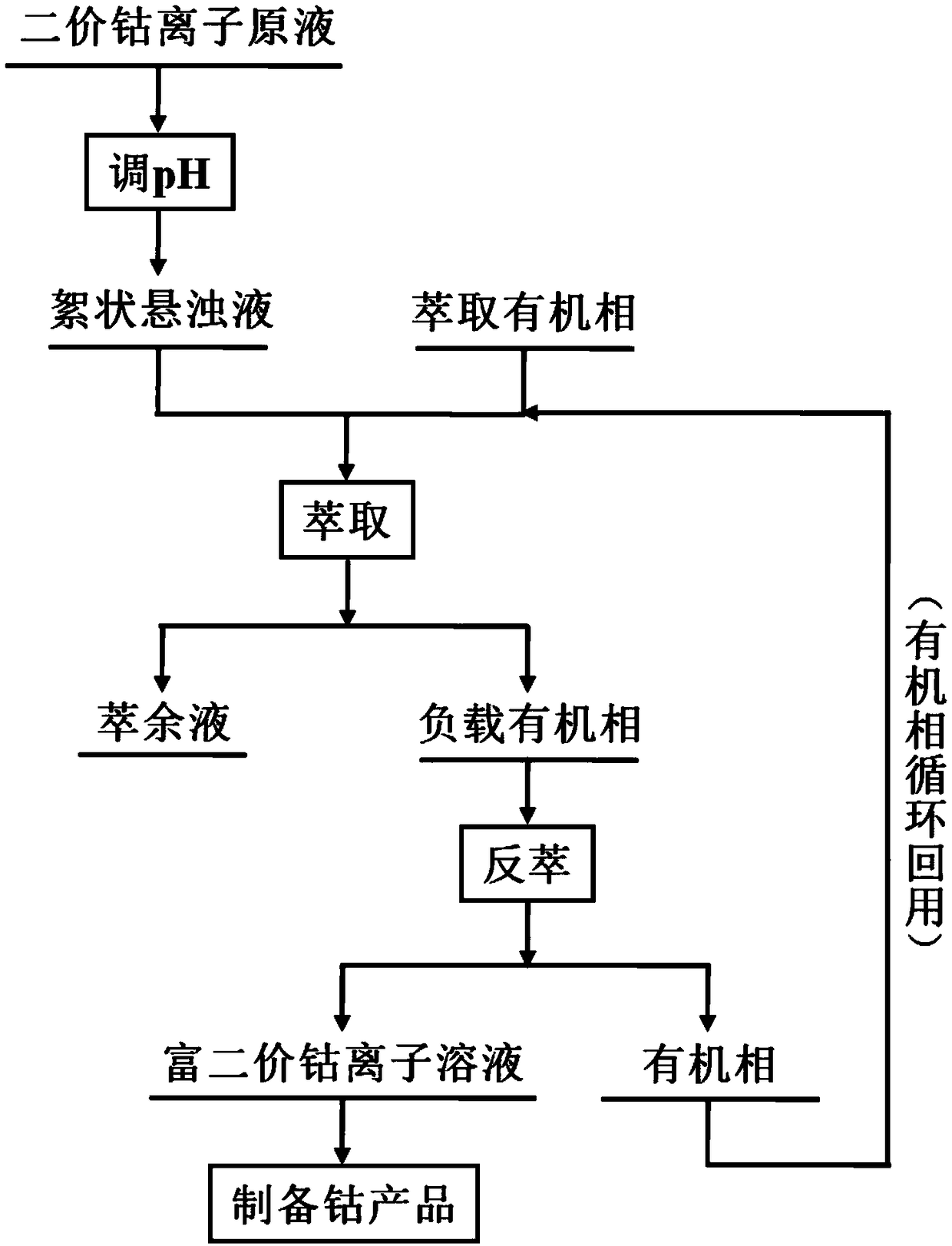

[0035] A kind of P204 method that the present embodiment provides extracts divalent cobalt ion, it comprises the following steps:

[0036] 1) The divalent cobalt ion stock solution containing divalent cobalt ion with a mass concentration of 1 g / L is adjusted to a pH value of 11.5 with sodium hydroxide, so that the divalent cobalt ion stock solution becomes a flocculent suspension;

[0037] 2) Using P204 as an extractant, adding sulfonated kerosene to prepare an extracted organic phase with a volume concentration of P204 of 8%;

[0038] 3) After mixing the flocculent suspension with the extracted organic phase, the extraction reaction is carried out, the extraction reaction time is 2min, and the ratio of the volume of the extracted organic phase to the volume of the flocculent suspension is 1:1.05;

[0039] 4) Back-extract the loaded organic phase obtained by extraction, and the stripping conditions are: the ratio (O / A) is 7, and the sulfuric acid with a concentration of 1.5mol...

Embodiment 2

[0044] A kind of P204 method that the present embodiment provides extracts divalent cobalt ion, it comprises the following steps:

[0045] 1) The divalent cobalt ion stock solution containing divalent cobalt ion with a mass concentration of 2g / L is adjusted to a pH value of 11 with sodium hydroxide, so that the divalent cobalt ion stock solution becomes a flocculent suspension;

[0046] 2) Using P204 as an extractant, adding sulfonated kerosene to prepare an extracted organic phase with a volume concentration of P204 of 6%;

[0047] 3) After mixing the flocculent suspension with the extracted organic phase, the extraction reaction is carried out, the extraction reaction time is 2min, and the ratio of the volume of the extracted organic phase to the volume of the flocculent suspension is 1:1;

[0048] 4) Back-extracting the loaded organic phase obtained by extraction, the stripping conditions are as follows: the ratio (O / A) is 5, the sulfuric acid with a concentration of 0.2mol / L...

Embodiment 3

[0052] A kind of P204 method that the present embodiment provides extracts divalent cobalt ion, it comprises the following steps:

[0053] 1) The divalent cobalt ion stock solution containing divalent cobalt ion mass concentration of 4g / L is adjusted to pH 12 with sodium hydroxide, so that the divalent cobalt ion stock solution becomes a flocculent suspension;

[0054] 2) taking P204 as an extractant, adding sulfonated kerosene to prepare an extracted organic phase with a volume concentration of P204 of 5%;

[0055] 3) After mixing the flocculent suspension with the extracted organic phase, the extraction reaction is carried out, the extraction reaction time is 5min, and the ratio of the volume of the extracted organic phase to the volume of the flocculent suspension is 1:0.9;

[0056] 4) Back-extract the loaded organic phase obtained by extraction, and the stripping conditions are: the ratio (O / A) is 10, and the sulfuric acid with a concentration of 2mol / L is used for strippi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com