Insert-buckled bullet-proof ceramic wafer and preparation method thereof

A ceramic sheet, embedded button technology, applied in the direction of the structure of the armor plate, can solve the problems of scattering, easy to be penetrated by bullets, etc., achieve long service life, increase the bonding area and bonding strength, and can be processed. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A method for preparing an embedded bulletproof ceramic sheet, comprising the following steps: step 1, weighing and mixing each raw material according to the weight percentage of claim 1 to form a mixture, placing the mixture in a ball mill for ball milling for 15 hours, and performing Drying treatment to obtain solid solution powder; wherein, an argon atmosphere is used during ball milling;

[0039] Step 2: Place the solid solution powder in a pre-prepared graphite mold, preload it in a press with a pressure of 5~10MPa for 10~25s, and cold press the solid solution powder to obtain a blank with the desired shape; wherein, cold pressing The molding pressure is 25~35MPa, and the holding time is 10~15min;

[0040] Step 3: Vacuum the inside of the sintering furnace, and the vacuum degree is 10 -2Pa, and then put the blank prepared in step 2 together with the mold into the sintering furnace for vacuum hot pressing sintering. The sintering temperature is 1500~1600°C, and it i...

Embodiment 1

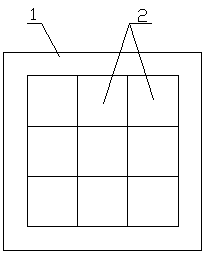

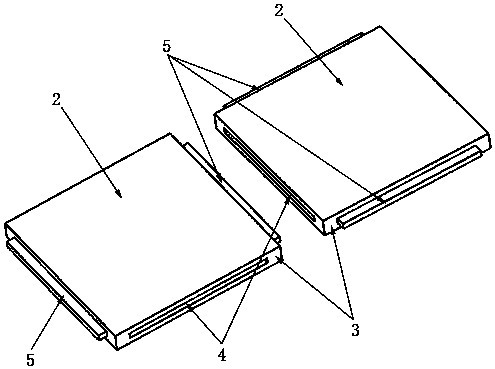

[0043] An embedded bulletproof ceramic sheet, the bulletproof ceramic sheet 2 has a square structure, and each bulletproof ceramic sheet 2 is formed by butting concave and convex embedded buttons. Such as figure 2 As shown, concave grooves are provided on the oppositely arranged edges 3 in the bulletproof ceramic sheet 2, and convex ridges 5 are provided on the edge 3 adjacent to the concave groove 4 in the bulletproof ceramic sheet 2, and the bulletproof ceramic sheet 2 is in the When docking, the edge 3 of a bulletproof ceramic sheet 2 provided with the concave groove 4 is interlocked with the edge 3 of the other bulletproof ceramic sheet 2 provided with the convex ridge 5 through the concave groove 4 and the convex ridge 5 . There is a clearance fit between the convex ridge 5 and the concave groove 4, and the concave groove 4 and the convex ridge 5 are respectively arranged in the middle of their respective edges, and the gap between the convex ridge 5 and the concave groo...

Embodiment 2

[0046] An embedded bulletproof ceramic sheet, such as Figure 4 As shown, the bulletproof ceramic sheet 2 has a square structure, and the bulletproof ceramic sheet 2 is formed by butting up and down. Such as Figure 5 As shown, the edge 3 of the bulletproof ceramic sheet 2 is provided with a concave groove 4 separated up and down and a convex ridge 5 protruding from the edge 3, and the concave groove 4 communicates with the convex ridge 5, wherein the bulletproof ceramic sheet 2 In the oppositely arranged edge 3, the concave groove 4 is located above the convex ridge 5, so that the cross-section of the end surface of the edge 3 along its center line has an L-shaped structure, that is, the two edges have a stepped structure; the bulletproof ceramic sheet In the remaining two edges 3 of 2, the convex ridge 5 is located above the concave groove 4, so that the cross-section of the end surface of the edge 3 along its center line is an inverted L-shaped structure; when the bulletpr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com