Preparation method capable of achieving large-scale preparation of Fe3O4@Aucore@shell structured nanorods with controllable size and dispersion

A large-scale preparation and nanorod technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as the difficulty of synthesizing superparamagnetic Fe, and achieve high grafting density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

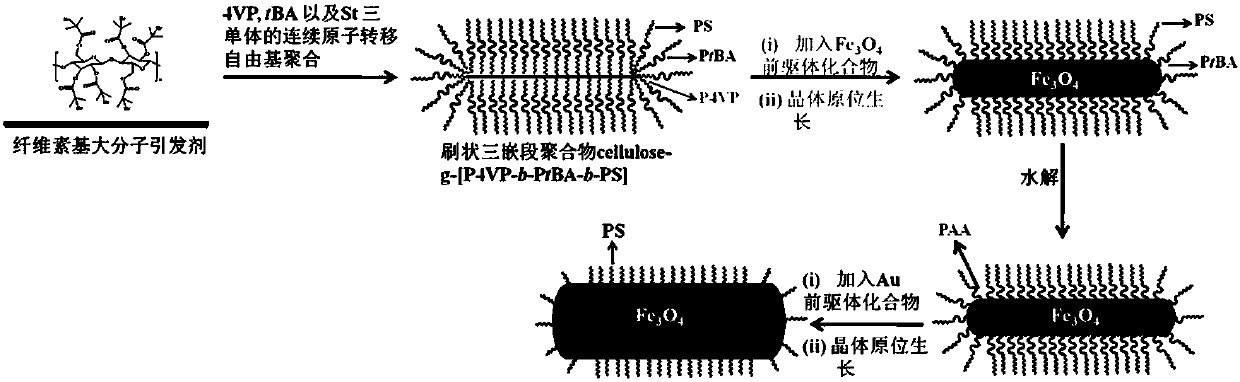

[0023] Example 1 ( figure 1 ).

[0024] The present invention will be further described below in conjunction with the examples, but the content of the present invention is not limited thereto.

[0025] (1) Preparation and classification of ATRP macroinitiator (cellulose-Br) based on cellulose molecules: In a 250mL single-necked flask, add 10g of natural cellulose, dissolve it in 100mL of ionic liquid 1-allyl-3-methylimidazolium chloride (AMIMCl ), when completely dissolved, add 10mL anhydrous DMF and 10mL NMP respectively as diluent and acid absorbent, slowly add 50mL 2-bromoisobutyryl bromide dropwise within 1 hour under the condition of cooling to zero degree, the modified cellulose The hydroxyl group on the chain is modified to convert it into a macromolecular initiator that can be used for ATRP. Then naturally warmed to room temperature (25 o C), react at room temperature for 24 hours. Finally, 500 mL of deionized water was used as a precipitating agent to precipitate ...

Embodiment 2

[0032] Example 2 ( Figure 5 ): Water-dispersible superparamagnetic Fe with core@shell structure 3 o 4 Preparation of @Au nanorods.

[0033] (1) Preparation of brush-shaped triblock polymers containing two-phase template structural units: using hydroxyl-modified cellulose cellulose-Br as a macromolecular initiator, comprehensively utilizing the experimental method of ATRP technology combined with "link" chemistry, A series of brush-like two-block polymers with PEG as the outermost segment were prepared by using the monofunctional polyethylene glycol mPEG modified with an alkyne group as the precursor of the outermost block: cellulose- g -[P4VP- b -P t BA- b -PEG].

[0034] (a) Preparation of mPEG whose end group is alkynyl group: through nucleophilic substitution reaction, prepare mPEG whose end group is alkynyl group (ie mPEG-propargyl), and use two kinds of molecular weight mPEG (referred to as mn =5,000 and mn =10,000). The specific steps are as follows: In a 250...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com