Method for coating nickel-cobalt lithium manganate and obtained nickel-cobalt lithium manganate material

A nickel-cobalt lithium manganese oxide coating technology, which is applied in the field of lithium-ion battery electrode materials, can solve the problems of reduced migration rate, interface impedance, cycle performance, and battery impedance, so as to increase Li+ migration rate and improve electrochemical performance. , The effect of small material phase impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

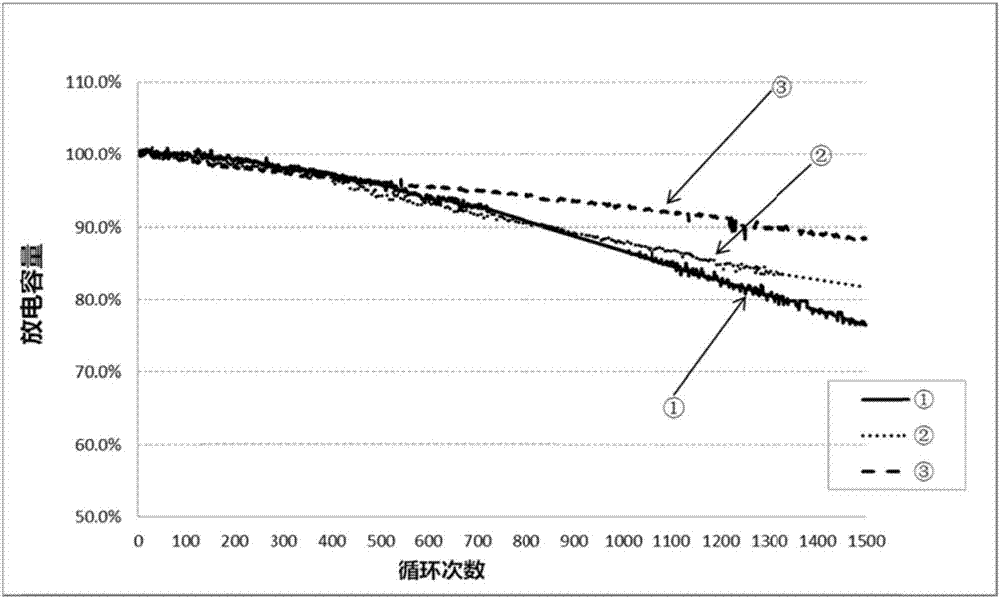

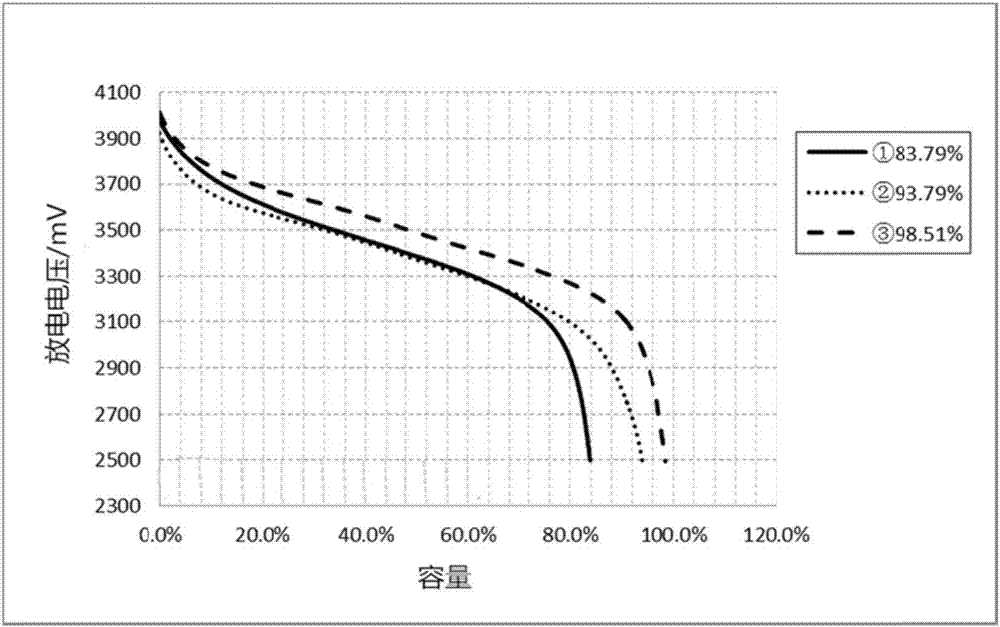

Examples

Embodiment 1

[0026] A method for coating nickel-cobalt lithium manganese oxide, prepared by the following steps:

[0027] a) Mix Ni in a certain proportion 1-x-y mn x co y (OH) 2 precursors and lithium salts to make Ni 1-x-y mn x co y (OH) 2 The molar ratio with Li is 1:0.9. When mixing, add the same volume of deionized water as the precursor and lithium salt. The mixture is sintered at 500°C for 5 hours, and then pulverized after sintering to obtain D 50 5~12μm powder; Ni 1-x-y mn x co y (OH) 2 In the precursor x=0.1, y=0.1, the precursor Ni 1-x-y mn x Ci y (OH) 2 The particle size is D 50 = 5 μm;

[0028] b) mix the powder obtained by step a with Ni 1-a-b mn a co b (OH) 2 The precursor and the lithium salt are mixed in a certain proportion, and the same volume of deionized water as the precursor and the lithium salt is added during mixing. Coated nickel cobalt lithium manganese oxide material; wherein Ni 1-a-b mn a co b (OH) 2 The molar ratio with Li is 1:0.9; Ni...

Embodiment 2

[0032] A method for coating nickel-cobalt lithium manganese oxide, prepared by the following steps:

[0033] a) Mix Ni in a certain proportion 1-x-y mn x co y (OH) 2 precursors and lithium salts to make Ni 1-x-y mn x co y (OH) 2 The molar ratio with Li is 1:1. When mixing, add the precursor and deionized water twice the volume of lithium salt. The mixture is sintered at 750°C for 10 hours, and then pulverized after sintering to obtain D 50 8μm powder; Ni 1-x-y mn x co y (OH) 2 In the precursor x=0.15, y=0.15, the precursor Ni 1-x-y mn x co y (OH) 2 The particle size is D 50 = 7μm;

[0034] b) mix the powder obtained by step a with Ni 1-a-b mn a co b (OH) 2 The precursor and the lithium salt were mixed in a certain proportion. When mixing, deionized water twice the volume of the precursor and the lithium salt was added. After the mixture was fully mixed, the liquid mixture was spray-dried and sintered in an air atmosphere at 850°C for 10 hours. Coated nicke...

Embodiment 3

[0038] A method for coating nickel-cobalt lithium manganese oxide, prepared by the following steps:

[0039] a) Mix Ni in a certain proportion 1-x-y mn x co y (OH) 2 precursors and lithium salts to make Ni 1-x-y mn x co y (OH) 2 The molar ratio with Li is 1:1. When mixing, add the precursor and deionized water twice the volume of lithium salt. The mixture is sintered at 750°C for 10 hours, and then pulverized after sintering to obtain D 50 8μm powder; Ni 1-x-y mn x co y (OH) 2 In the precursor x=0.15, y=0.15, the precursor Ni 1-x-y mn x co y (OH) 2 The particle size is D 50 = 7μm;

[0040] b) mix the powder obtained by step a with Ni 1-a-b mn a co b (OH) 2 The precursor and the lithium salt were mixed in a certain proportion. When mixing, deionized water twice the volume of the precursor and the lithium salt was added. After the mixture was fully mixed, the liquid mixture was spray-dried and sintered in an air atmosphere at 850°C for 10 hours. Coated nicke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com