Flexible composite thermoelectric thin film and preparation method therefor

A thermoelectric thin film, flexible technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric device node lead-out materials, nanotechnology, etc., can solve the problem of low power factor of composite materials, achieve low cost, simple raw materials, and preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

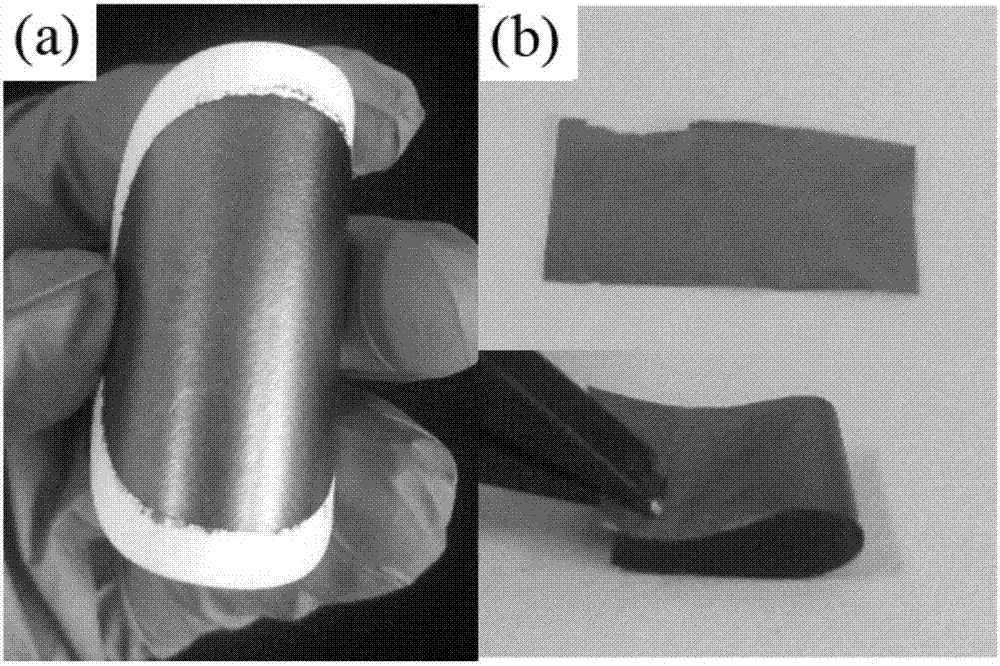

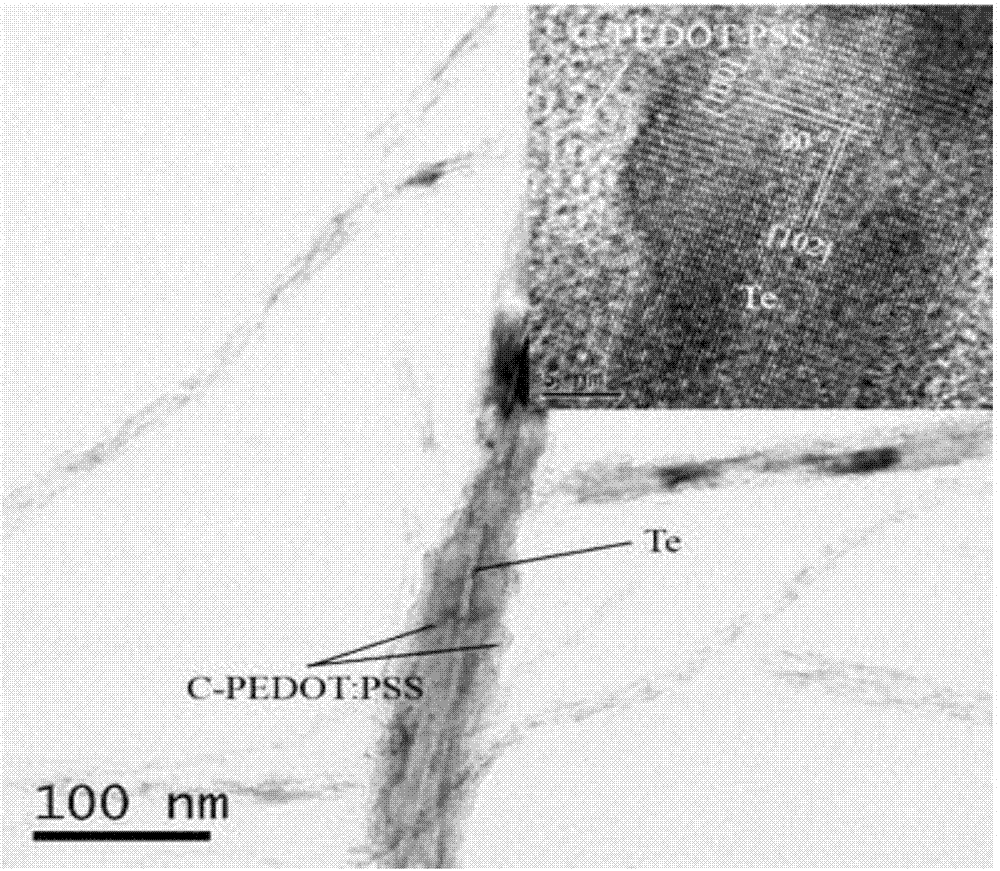

[0038] The flexible composite thermoelectric film is made of PEDOT:PSS, tellurium nanowires, and glucose; the mass ratio of tellurium nanowires to glucose is 1.68:1; the mass ratio of tellurium nanowires to PEDOT:PSS is 9:1.

[0039] The preparation method of the flexible composite thermoelectric film includes:

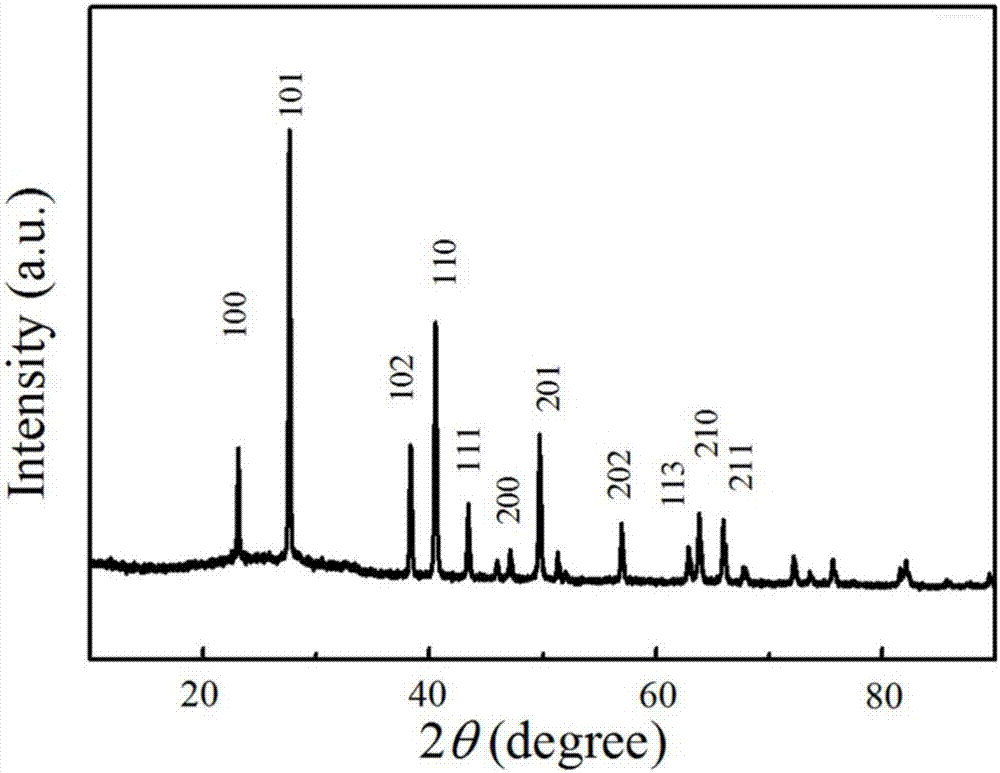

[0040] Step 1: Preparation of Te nanowires

[0041] Weigh 0.1884g Na 2 TeO 3 , Dissolve 1.000g of PVP in 50mL of deionized water and dissolve completely under magnetic stirring. Use a pipette to measure 3.3mL of hydrazine hydrate and 6.7mL of ammonia water (25-28%), and stir for 20min to promote their complete dissolution. Add the above solution into the inner tank of the reaction kettle, and add deionized water to make the solution reach 80% of the total capacity of the inner tank (the total volume of the polytetrafluoroethylene container is 100 mL). The reaction kettle was placed in an oven at 180° C. for 3.5 h, cooled to room temperature in a water bath, and an ...

Embodiment 2

[0049] The flexible composite thermoelectric film is made of PEDOT:PSS, tellurium nanowires, and glucose; the mass ratio of tellurium nanowires to glucose is 1.68:1; the mass ratio of tellurium nanowires to PEDOT:PSS is 4:1.

[0050] The preparation method is the same as in Example 1.

[0051] Figure 4-5 As shown, the electrical conductivity of the prepared flexible composite thermoelectric film is 35.65S / cm, and the Seebeck coefficient is 163.65μV / K.

Embodiment 3

[0053] The flexible composite thermoelectric film is made of PEDOT:PSS, tellurium nanowires, and glucose; the mass ratio of tellurium nanowires to glucose is 1.68:1; the mass ratio of tellurium nanowires to PEDOT:PSS is 7:3.

[0054] The preparation method is the same as in Example 1.

[0055] Figure 4-5 As shown, the electrical conductivity of the prepared flexible composite thermoelectric film is 38.7S / cm, and the Seebeck coefficient is 134.9μV / K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| Seebeck coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com