Boiler waste heat recycling system based on flue gas waste heat recovery boiler economizer

A technology for waste heat recovery from flue gas and boilers, applied in water heaters, fluid heaters, greenhouse gas reduction, etc., can solve the problems of huge environmental pollution, waste of heat, etc., and achieve high heat exchange efficiency, no operating costs, and improved The effect of using efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

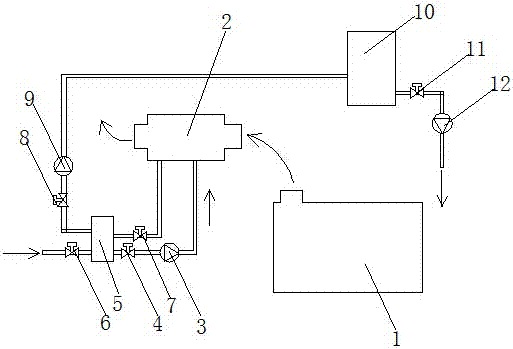

[0014] Such as figure 1 A boiler waste heat recycling system based on a flue gas waste heat recovery boiler economizer shown includes a boiler 1 and a flue gas waste heat recovery device 2; the flue gas waste heat recovery device 2 is installed at the flue outlet of the boiler 1; the One end of the flue gas waste heat recovery device 2 is connected to tap water through the first heat recovery pump 3, the second shut-off valve 4, the heat preservation hot water tank 5 and the first shut-off valve 6; The valve 7, the heat preservation hot water tank 5, the fourth stop valve 8 and the second heat recovery pump 9 are connected to the heat preservation water tank 10;

[0015] A plurality of heat transfer elements (not shown) and pressure regulating valves are installed in the flue gas waste heat recovery device 2; the heat transfer elements are assembled to form a fluid channel, which can generate turbulent flow at a low Reynolds number and is not easy to scale .

[0016] The hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com