Tyre inner liner composite material and preparation method thereof

A composite material and airtight layer technology, applied in building insulation materials, building components, buildings, etc., can solve problems such as damage, achieve good shielding effect, improve flex fatigue resistance, and improve the effect of excessive hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

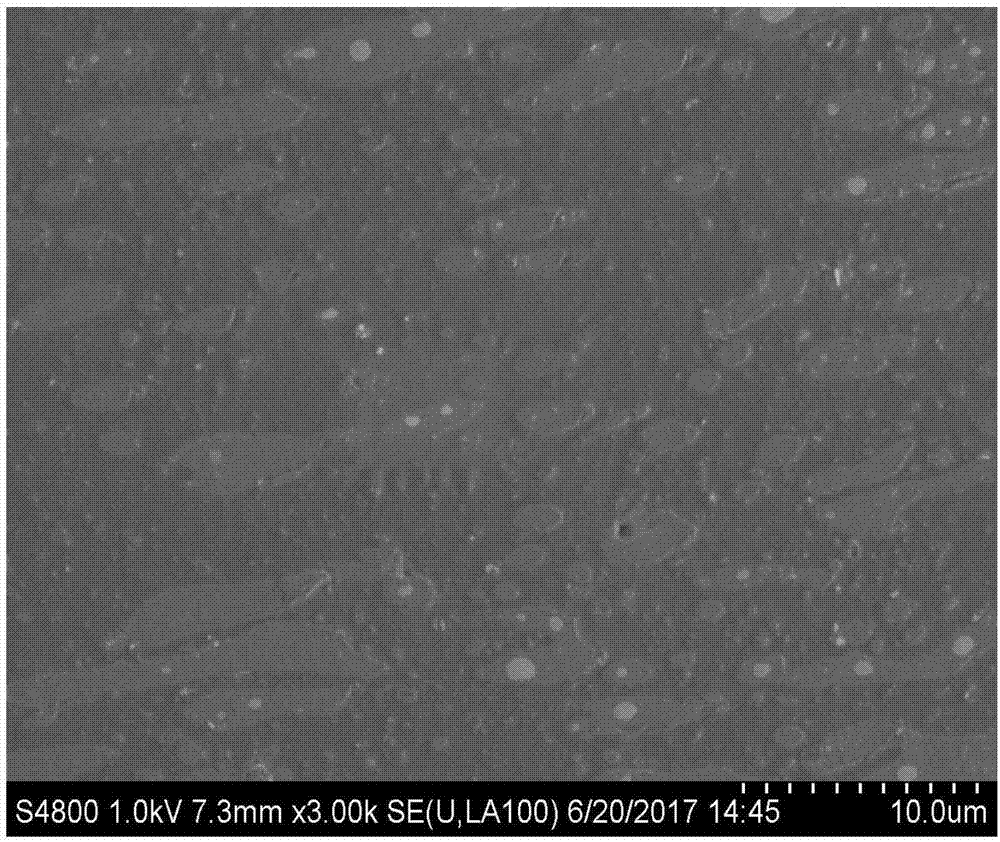

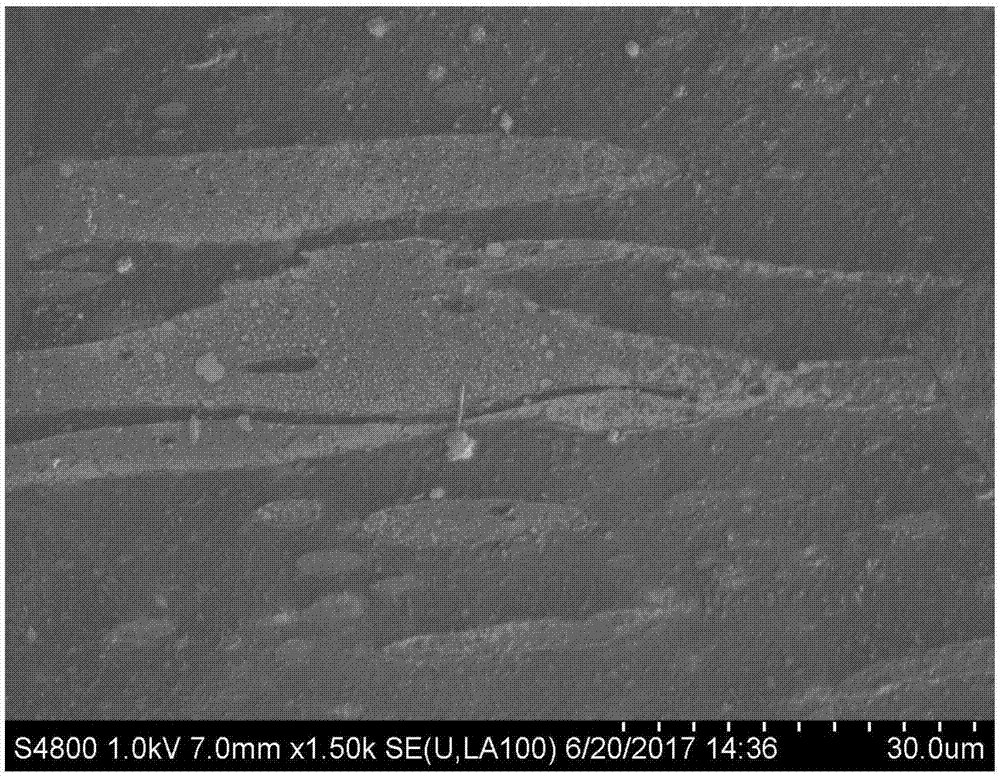

Image

Examples

Embodiment 1

[0034] The formula consists of the following raw materials in parts by weight: 80 parts of bromobutyl rubber BIIR, 20 parts of nitrile rubber NBR (3365), 2 parts of nanoclay, 5 parts of modified asphalt (CJ-100), 3 parts of zinc oxide, oxide 0.1 part of magnesium, 1 part of stearic acid, 40202 parts of anti-aging agent, 1 part of anti-aging agent RD, 10 parts of aromatic oil, 3 parts of DOP, 60 parts of carbon black, 1.5 parts of accelerator DM, and 0.5 parts of sulfur.

[0035] Preparation:

[0036] First prepare the masterbatch of nitrile rubber / nano-clay on the open mill, then transfer to the internal mixer, add BIIR, NBR / nano-clay masterbatch, modified asphalt (CJ-100) and then at 90°C at a speed of 40r / min Add ZnO, MgO, SA 2 minutes after the torque is stable, add antioxidant 4020, anti-aging agent RD after the torque is stable for 1 minute, add half of the carbon black, aromatic oil and DOP after the torque is stable for 1 minute, add the other half of the carbon black a...

Embodiment 2

[0039]The formula consists of the following raw materials in parts by weight: 70 parts of bromobutyl rubber BIIR, 30 parts of nitrile rubber NBR (3365), 3 parts of nanoclay, 7.5 parts of modified asphalt (CJ-100), 3 parts of zinc oxide, oxide 0.1 part of magnesium, 1 part of stearic acid, 2 parts of anti-aging agent 4020, 1 part of anti-aging agent RD, 10 parts of aromatic oil, 3 parts of DOP, 60 parts of carbon black, 1.5 parts of accelerator DM, and 0.5 parts of sulfur.

Embodiment 3

[0041] The formula is composed of the following raw materials in parts by weight: bromobutyl rubber BIIR 60 parts, nitrile rubber NBR (3365) 40 parts, nano clay 4 parts, modified asphalt (CJ-100) 10 parts, zinc oxide 3 parts, oxide 0.1 part of magnesium, 1 part of stearic acid, 2 parts of anti-aging agent 4020, 1 part of anti-aging agent RD, 10 parts of aromatic oil, 3 parts of DOP, 60 parts of carbon black, 1.5 parts of accelerator DM, and 0.5 parts of sulfur.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| gas permeability | aaaaa | aaaaa |

| gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com