Method for synthesizing high-purity 3,3',5,5'-tetramethyl-4,4'-biphenyl diquinone through Cu-BTC catalysis

A technology of diphenyl diquinone and tetramethyl, applied in the field of fine chemicals, can solve the problems of easy decomposition, increased separation difficulty and cost, low product yield, etc., and achieves the effects of simple equipment, short cycle and few by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

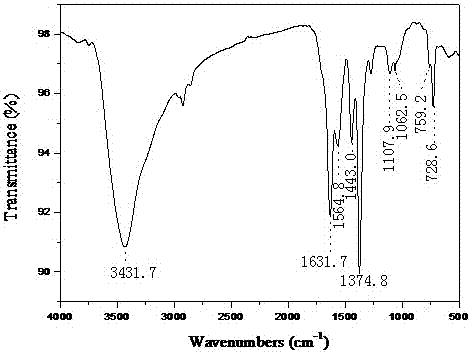

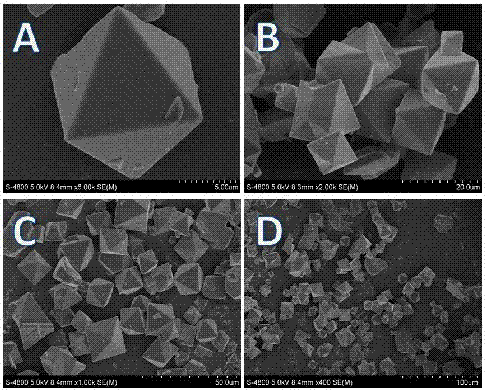

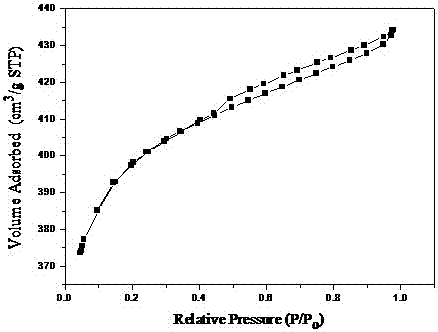

[0032] 1. Preparation of Cu-BTC

[0033] Weigh 4g copper nitrate trihydrate and add it to 25ml ultrapure water, add 2g trimesic acid to 25ml ethanol, ultrasonically dissolve the two solutions respectively for 20min, slowly add trimesic acid dissolved in ethanol to A mixed solution was formed in the aqueous solution of copper nitrate trihydrate, and after continuing to stir for 30 minutes, the mixed solution was transferred to a 100ml sealed reaction kettle with a polytetrafluoroethylene liner, sealed, heated to 110°C for 18 hours of crystallization, and then cooled to room temperature. The precipitate was obtained, centrifuged, and the precipitate was dried in an oven at 100°C for 6 hours to obtain a blue powder. Transfer the blue powder sample to a Soxhlet extractor, add 40ml of ethanol, and remove it after Soxhlet extraction for 12 hours. Vacuum drying in a vacuum oven at 100° C. and a vacuum degree of 0.1 MPa for 10 hours, and cooling to obtain a Cu-BTC catalyst.

[0034] ...

Embodiment 2

[0036] Example 2 The operation steps are the same as in Example 1, but the surfactant dosage is 0.05 g, and the product quality yield is 91.5%, and the purity is 96.3%.

Embodiment 3

[0037] Example 3 The operation steps are the same as in Example 1, but no surfactant is added to obtain a product with a mass yield of 27.9% and a purity of 32.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com