Preparation method of black-odor river sediment covering material

A technology for covering materials and river bottom mud, which is applied in the field of preparation of black and odorous river bottom mud covering materials, can solve problems such as easy to cause anaerobic or facultative anaerobic environment, can not achieve water quality improvement effect, and can not be realized at the same time, to achieve construction Convenience, low cost, large specific effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present embodiment provides a method for preparing a black and odorous river channel bottom mud covering material, comprising the following steps:

[0030] (1) mix 100 parts by mass of fly ash and 10 parts by mass of polylactic acid-coated calcium peroxide, and stir at 90-150 rpm for 15-30min, so that the surface of the oxygen slow-release material is wrapped by fly ash to obtain the first mixed material ;

[0031] (2) the first mixed material is mixed with silicate, and stirred at 90-150rpm for 15-30min to obtain the second mixed material;

[0032] (3) adding 40 parts by mass of water to the second mixed material obtained in step (2) and stirring to obtain a mixture, which is loaded into a honeycomb die and extruded to obtain a solidified body precursor of a honeycomb structure;

[0033] (4) air-drying the cured body precursor in the step (3) in a natural state for one week to obtain a cured body;

[0034] (5) The solidified body obtained in step (4) is heated un...

Embodiment 2

[0036] (1) 100 parts by mass of fly ash and 10 parts by mass of polylactic acid wrapped calcium peroxide and magnesium peroxide mixture are mixed, and stirred at 90-150rpm for 15-30min, so that the surface of the oxygen slow-release material is wrapped by fly ash, to obtain the first mixed material;

[0037] (2) the first mixed material is mixed with 30 parts by mass of active magnesium oxide, and stirred for 15-30min at 90-150rpm to obtain the second mixed material;

[0038] (3) adding 50 parts by mass of water to the second mixed material obtained in the step (2) and stirring to obtain a mixture, and packing the mixture into a honeycomb die for extrusion molding to obtain a solidified body precursor of a honeycomb structure;

[0039] (4) air-drying the cured body precursor in the step (3) for one week in a natural state to obtain a cured body with a size of 10 mm;

[0040] (5) The solidified body obtained in the step (4) is heated under the protection of nitrogen, placed in...

Embodiment 3

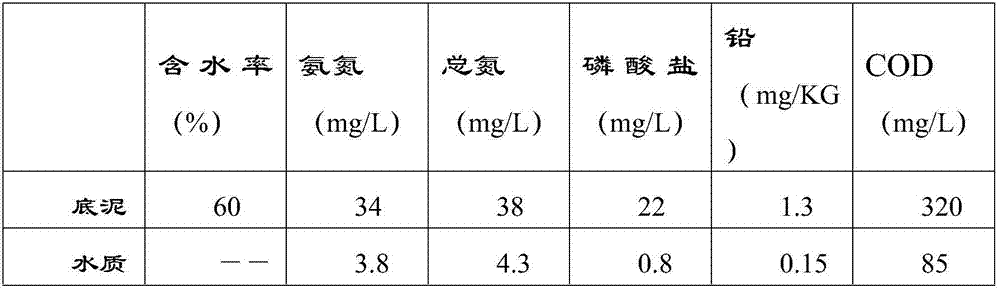

[0061] Use the covering material A to repair the black and odorous river sediment; obtain 20 kg of sediment and record the sludge and water quality parameters (Table 2), pour the sludge into a drum, the thickness of the mud is about 40cm, and then pour the Contaminated clean water, the water surface is 40cm away from the upper surface of the sediment. After the water is stabilized, the surface is evenly scattered with covering material A2KG to form a covering layer with a thickness of about 2cm. After three months, the water quality changes are observed, and the results are recorded in Table 3; Sediment, test the parameters of the sediment, see Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com