Welding process for straight seam welded pipe

A technology of straight seam welded pipe and welding process, which is applied in the direction of welding equipment, manufacturing tools, tubular objects, etc., which can solve the problems of unsatisfactory welding quality, long welding operation time, and heavy welding workload, so as to avoid weld spatter or welding Parts are not penetrated, welding production efficiency is high, and welding speed is fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

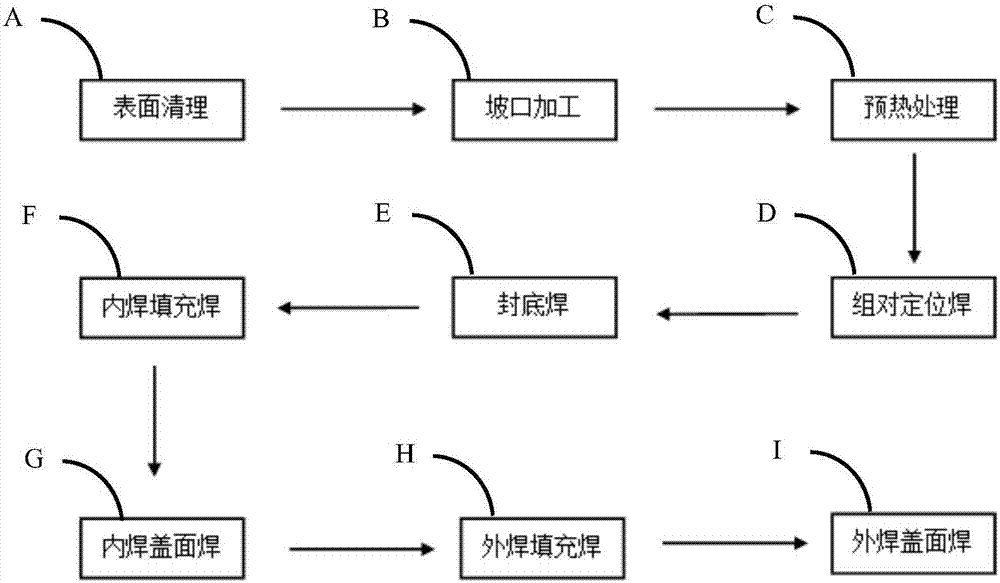

[0070] A. Surface cleaning. The surface cleaning of the steel is to remove the oil stains, oxides and rust on the groove surface and its edge within 50mm. Specifically, surface cleaning is to use an angle grinder to polish and polish the rust and oxides on the steel plate to expose the metallic luster of the steel plate, and then use acetone solution to remove oil stains on the steel plate.

[0071] B. Groove processing. The steel plate is beveled to obtain a rolled steel plate.

[0072] C. Preheat treatment. Perform preheating treatment on the coiled steel plate, wherein the preheating range of the preheating treatment is based on the center line of the groove, and the two sides are not less than three times the wall thickness of the steel plate and not less than 100mm , and keep warm within 100mm outside the preheating range.

[0073] The preheating treatment adopts a crawler heater or a flamer for preheating, and the preheating temperature is greater than 200°C.

[007...

Embodiment 2

[0091]A. Surface cleaning. The surface cleaning of the steel is to remove the oil stains, oxides and rust on the groove surface and its edge within 50mm. Specifically, surface cleaning is to use an angle grinder to polish and polish the rust and oxides on the steel plate to expose the metallic luster of the steel plate, and then use acetone solution to remove oil stains on the steel plate.

[0092] B. Groove processing. The steel plate is beveled to obtain a rolled steel plate.

[0093] C. Preheat treatment. Perform preheating treatment on the coiled steel plate, wherein the preheating range of the preheating treatment is based on the center line of the groove, and the two sides are not less than three times the wall thickness of the steel plate and not less than 100mm , and keep warm within 100mm outside the preheating range.

[0094] The preheating treatment adopts a crawler heater or a flamer for preheating, and the preheating temperature is greater than 200°C.

[0095...

Embodiment 3

[0112] A. Surface cleaning. The surface cleaning of the steel is to remove the oil stains, oxides and rust on the groove surface and its edge within 50mm. Specifically, surface cleaning is to use an angle grinder to polish and polish the rust and oxides on the steel plate to expose the metallic luster of the steel plate, and then use acetone solution to remove oil stains on the steel plate.

[0113] B. Groove processing. The steel plate is beveled to obtain a rolled steel plate.

[0114] C. Preheat treatment. Perform preheating treatment on the coiled steel plate, wherein the preheating range of the preheating treatment is based on the center line of the groove, and the two sides are not less than three times the wall thickness of the steel plate and not less than 100mm , and keep warm within 100mm outside the preheating range.

[0115] The preheating treatment adopts a crawler heater or a flamer for preheating, and the preheating temperature is greater than 200°C.

[011...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com