Preparation method of catalyst for treatment of biorefractory industrial organic wastewater

A technology for industrial wastewater and catalysts, which is applied in catalyst activation/preparation, physical/chemical process catalysts, catalyst carriers, etc., and can solve the problems of difficult separation of solid-liquid two-phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

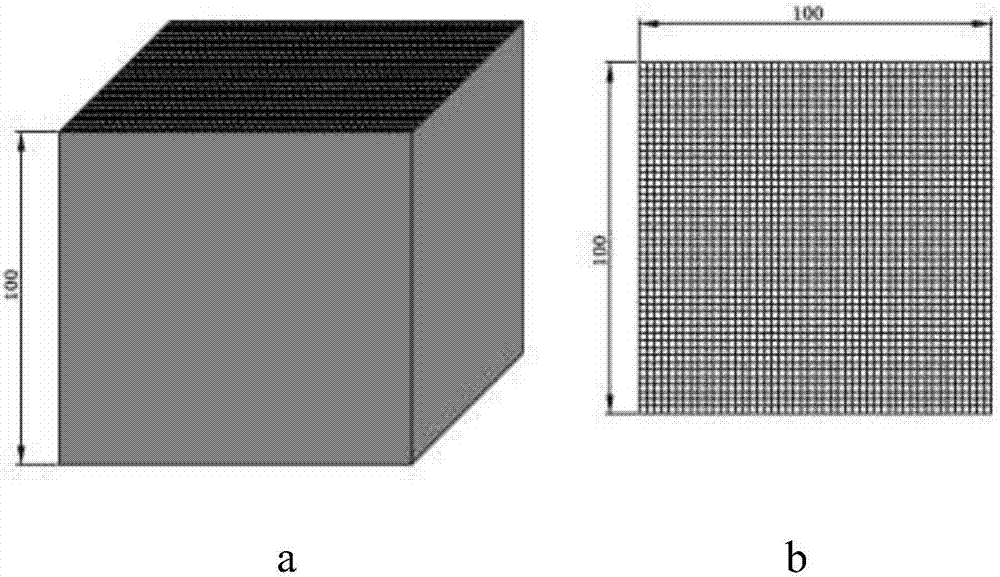

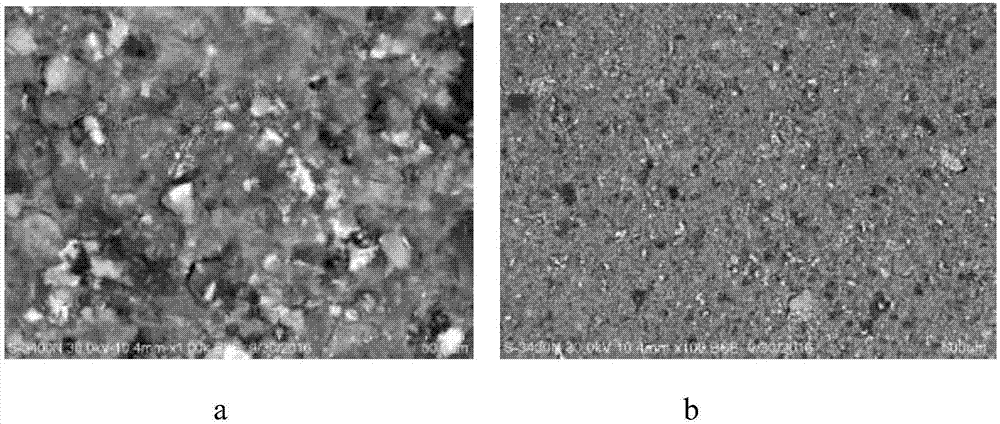

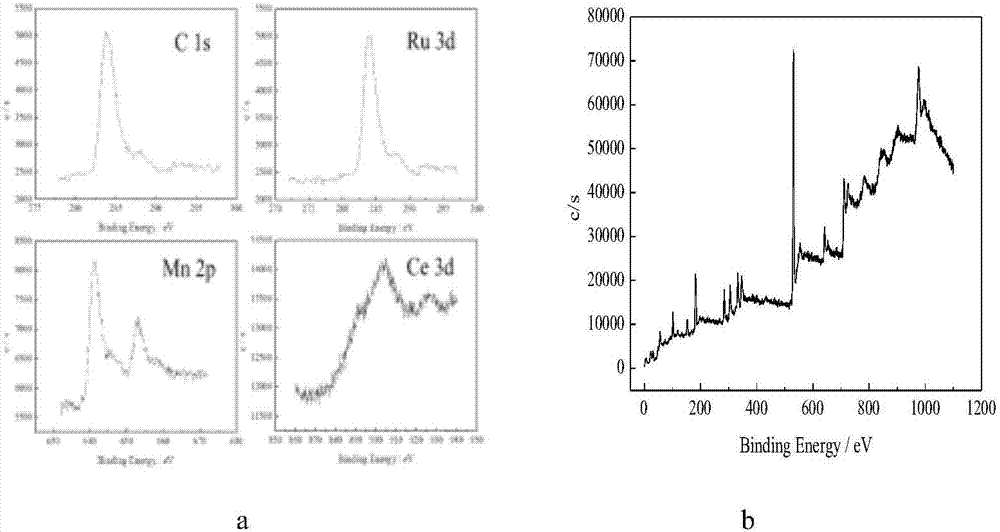

[0022] Example 1: Weighing 10g honeycomb carrier placed in 5% NaOH solution and diluted 5 times HNO 3 Purify and dry in the solution; accurately weigh 0.9295g of 3% cerium nitrate and 0.9352g of 3% lanthanum nitrate and dissolve it in 100mL of water, stir and dissolve and continue to stir for 24 hours, take it out and wash it with deionized water several times, and dry it at 80°C , baked for 2 hours under a nitrogen atmosphere in the temperature range of 400°C-600°C; to γ-Al 2 o 3 Add the same quality of water and stir evenly, weigh the precious metals Ru, Pt and Pd in a molar ratio of 3:1:1, and the mass is 0.0157g, 0.0038g, 0.0068g to 3g γ-Al 2 o 3 In the aqueous solution, add ferric nitrate, manganese nitrate and ammonium metavanadate at the same time according to the molar ratio of Fe:Mn:V about 2:2:1. 3 and NH 3 ·H 2 O adjust the pH within the range of 4-7, stir for 2 hours, dry and grind to make a coating material, make the above coating material into a slurry, co...

example 2

[0023] Example two: weigh 100g of honeycomb carrier and place it in 5% NaOH solution and dilute 5 times of HNO 3 Purify and dry in the solution; accurately weigh 9.29g of 3% cerium nitrate and 9.35g of 3% lanthanum nitrate and dissolve it in 1000mL of water, stir to dissolve and continue to stir for 24 hours, take it out and wash it with deionized water several times, and dry it at 80°C , baked for 2 hours under a nitrogen atmosphere in the temperature range of 400°C-600°C; to γ-Al 2 o 3 Add the same quality of water and stir evenly, weigh the precious metals Ru, Pt and Pd in a molar ratio of 3:1:1, and the mass is 0.157g, 0.038g, 0.068g to 30g γ-Al 2 o 3 In the aqueous solution, add iron nitrate, manganese nitrate and ammonium metavanadate at the same time according to the molar ratio of Fe:Mn:V about 2:2:1. 3 and NH 3 ·H 2 O adjust the pH within the range of 4-7, stir for 2 hours, dry and grind to make a coating material, make the above coating material into a slurry,...

example 3

[0024] Example three: weigh 1000g of honeycomb carrier and place it in 5% NaOH solution and dilute 5 times of HNO 3 Purify and dry in the solution; accurately weigh 92.9g of 3% cerium nitrate and 93.5g of 3% lanthanum nitrate and dissolve in 10000mL of water, stir and dissolve and continue to stir for 24 hours, take it out and wash it with deionized water several times, at 80°C After drying, it is calcined for 2 hours under a nitrogen atmosphere in the temperature range of 400°C-600°C; to γ-Al 2 o 3Add the same quality of water and stir evenly, and weigh the precious metals Ru, Pt and Pd in the ratio of 3:1:1 by molar ratio. The mass is 1.57g, 0.38g, 0.68g to 300gγ-Al 2 o 3 In the aqueous solution, add iron nitrate, manganese nitrate and ammonium metavanadate at the same time according to the molar ratio of Fe:Mn:V about 2:2:1. 3 and NH 3 ·H 2 O adjust the pH within the range of 4-7, stir for 2 hours, dry and grind to make a coating material, make the above coating mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chroma | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com