Bleed-free injection needle coated with crosslinked chitosan having introduced catechol group and oxidized catechol group

A catechol group and injection needle technology, which is applied in the field of hemostatic injection needles, can solve the problems of not fully satisfying adhesion strength persistence, low toxicity in vivo immune response, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

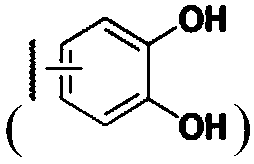

[0076] Preparation Example 1: Preparation of Chitosan Introducing Catechol

[0077]

[0078] 3 g of about 30% acetylated chitosan (chitosan 70 / 100, model: 24204, manufactured by Heppe Medical Chitosan) was dissolved in 292 mL of HCl solution (pH=2) for 6 hours. The chitosan solution was adjusted to pH 5.5 by slowly adding 8 mL of 0.5 N NaOH solution thereto. The prepared 1% chitosan solution was stabilized for 12 hours.

[0079] 2.37 g of 3-(3,4-dihydroxyphenyl)propionic acid was added to the prepared chitosan solution. Then, as the amine (-NH 2 ) group and the amide bond (-CONH-) between the carboxyl group (-COOH) of 3-(3,4-dihydroxyphenyl) propionic acid -Dimethylaminopropyl)carbodiimide (EDC) was dissolved in 50 mL ethanol and added to the chitosan solution. Next, the solution was adjusted to pH 4.5, followed by reaction for 1 hour. In this process, catechol-functionalized chitosan was prepared.

[0080]In order to remove unreacted 3-(3,4-dihydroxyphenyl) propion...

Embodiment 1

[0081] Embodiment 1: Manufacture of hemostatic injection needle (26G) 1

[0082] 1.5 mL of the catechol-functionalized chitosan prepared in Preparation Example 1 was dissolved in 100 μL of triple distilled water, and then stored at 4° C. for 3 days to induce partial oxidation and crosslinking of catechol groups. As a result, a chitosan solution (hereinafter referred to as "chitosan-catechol solution") was prepared in which catechol groups were introduced and oxidized catechol groups and partially cross-linked.

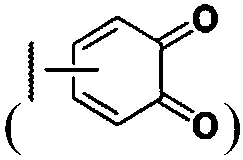

[0083] The absorbance at a wavelength of 500 nm was measured by UV-Vis spectroscopy to determine the degree of oxidation of catechol groups in chitosan-catechol solutions. Absorbance at a wavelength of 500 nm occurs when crosslinks between the oxidized catechol groups and the amine groups of chitosan are formed. Therefore, based on the absorbance that occurs, NaIO 4 (ie, an oxidizing agent that induces the oxidation of the chitosan-catechol solution to the high...

Embodiment 2

[0085] Embodiment 2: Manufacture of hemostatic injection needle (23G) 1

[0086] A hemostatic injection needle was manufactured in the same manner as described in Example 1, except that a 23G thick injection needle was used instead of a 26G thick injection needle, and a chitosan-catechol solution in an amount of 9 μL was used instead of 6.5 μL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com