Debugging method and thermal evaporator

A debugging method and evaporation machine technology, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems of slow debugging speed, color mixing effect, waste, etc., so as to save organic materials and speed up The effect of debugging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

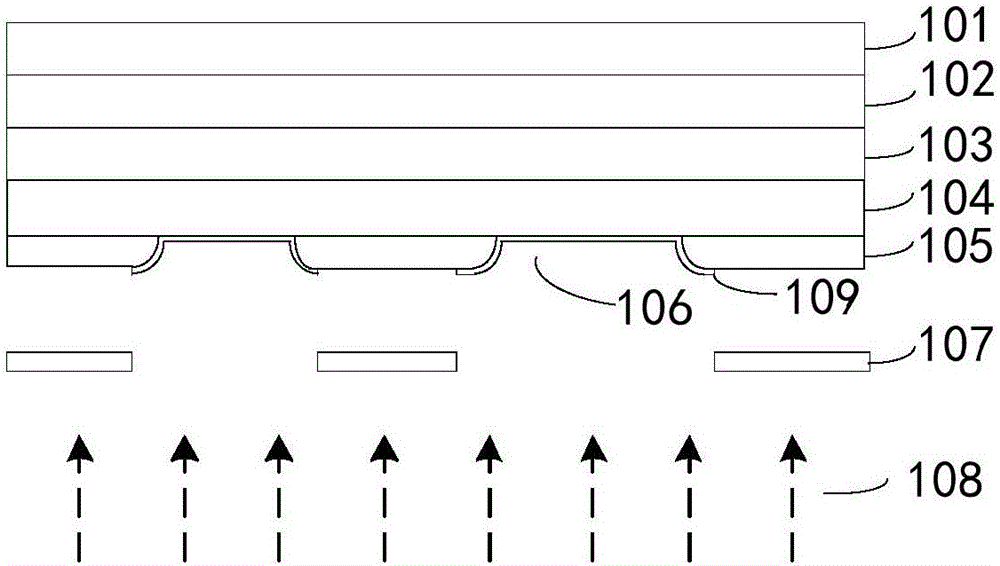

[0025] refer to figure 1 , figure 1 It is a schematic diagram of a debugging substrate and a precision mask plate in the common technology during debugging. The debugging substrate includes: a substrate 101 , a buffer layer 102 , a metal layer 103 , an anode thin film layer 104 and a photoresist layer 105 .

[0026] The substrate 101 is a glass substrate or a substrate having a double-layer structure of a glass substrate and a polyimide film. The material of the buffer layer 102 is silicon nitride or silicon oxide, wherein the buffer layer 102 can be more than one layer, and can be two layers. figure 1 The buffer layer 102 is used as a layer for schematic illustration. The metal layer 103 is a metal molybdenum layer or a multi-layer thin film layer formed of multiple metals, and is used to form an alignment mark of the substrate for debugging. The anode film layer 104 is a multilayer structure formed of indium tin oxide and metal silver. Usually, the anode film layer 104 un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com