Shell-imitated ceramic-based composite material and preparation method thereof

A composite material and ceramic-based technology, applied in the field of shell-like ceramic-based composite materials and their preparation, can solve the problem of insufficient mechanical properties and achieve the effect of improving strength and fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

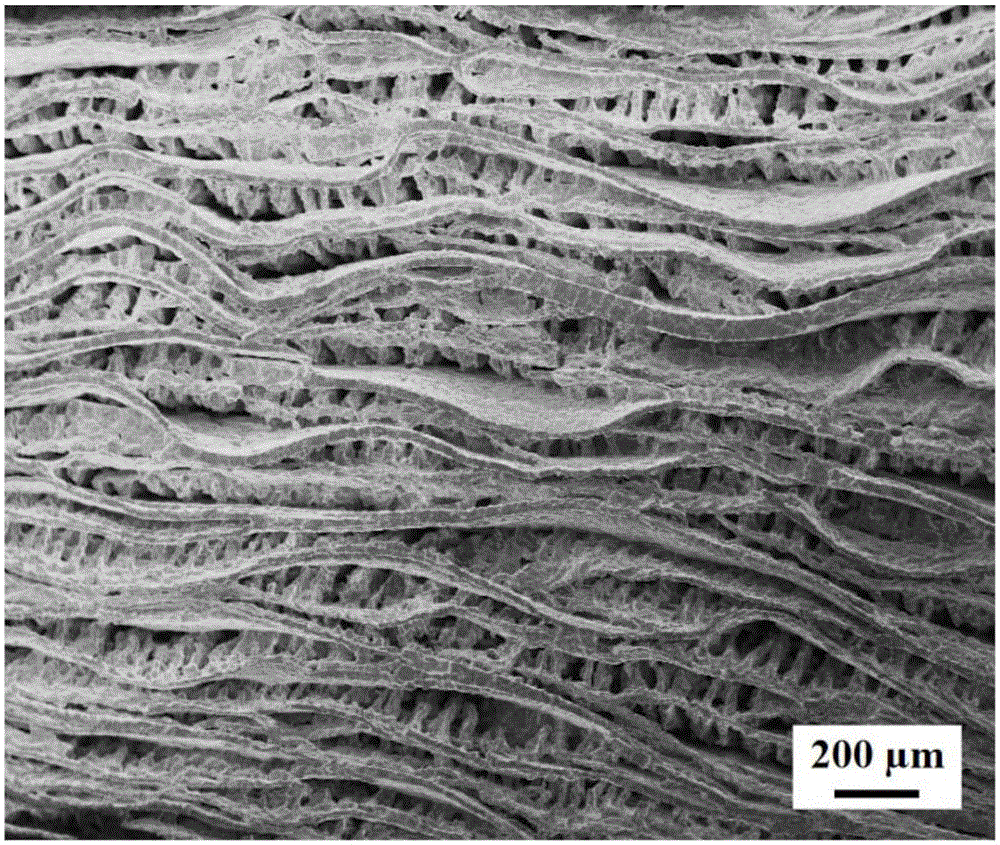

Image

Examples

Embodiment 1

[0043] 1) Pour alumina powder and polyvinyl alcohol accounting for 2 wt% of the alumina powder into deionized water, and stir evenly to obtain an aqueous dispersion of alumina ceramic particles with an alumina content of 15 wt%.

[0044] 2) Place the water dispersion of aluminum oxide ceramic particles obtained in step 1) into a water cup-shaped freezing mold made of a metal rod inserted into the bottom of the polytetrafluoroethylene tube, and then immerse the metal rod at the bottom of the freezing mold in the In the refrigerant, the ceramic particle aqueous dispersion is directional frozen through the heat transfer of the metal rod until the ceramic particle aqueous dispersion is completely frozen, that is, an ice cube containing the ceramic particle assembly is obtained.

[0045] 3) Freeze-dry the ice cube containing the ceramic particle assembly obtained in step 2) for 48 hours at a temperature lower than -25°C and an air pressure lower than 100 Pa to obtain a porous alumin...

Embodiment 2

[0053] 1) Pour alumina powder and polyvinyl alcohol accounting for 4 wt% of the alumina powder into deionized water, and stir evenly to obtain an aqueous dispersion of alumina ceramic particles with an alumina content of 20 wt%.

[0054] 2) Place the water dispersion of aluminum oxide ceramic particles obtained in step 1) into a water cup-shaped freezing mold made of a metal rod inserted into the bottom of the polytetrafluoroethylene tube, and then immerse the metal rod at the bottom of the freezing mold in the In the refrigerant, the ceramic particle aqueous dispersion is directional frozen through the heat transfer of the metal rod until the ceramic particle aqueous dispersion is completely frozen, that is, an ice cube containing the ceramic particle assembly is obtained.

[0055] 3) Freeze-dry the ice cube containing the ceramic particle assembly obtained in step 2) for 48 hours at a temperature lower than -25°C and an air pressure lower than 100 Pa to obtain a porous alumin...

Embodiment 3

[0063] 1) Pour alumina powder and polyvinyl alcohol accounting for 5 wt% of the alumina powder into deionized water, and stir evenly to obtain an aqueous dispersion of alumina ceramic particles with an alumina content of 25 wt%.

[0064] 2) Place the water dispersion of aluminum oxide ceramic particles obtained in step 1) into a water cup-shaped freezing mold made of a metal rod inserted into the bottom of the polytetrafluoroethylene tube, and then immerse the metal rod at the bottom of the freezing mold in the In the refrigerant, the ceramic particle aqueous dispersion is directional frozen through the heat transfer of the metal rod until the ceramic particle aqueous dispersion is completely frozen, that is, an ice cube containing the ceramic particle assembly is obtained.

[0065] 3) Freeze-dry the ice cube containing the ceramic particle assembly obtained in step 2) for 48 hours at a temperature lower than -25°C and an air pressure lower than 100 Pa to obtain a porous alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com