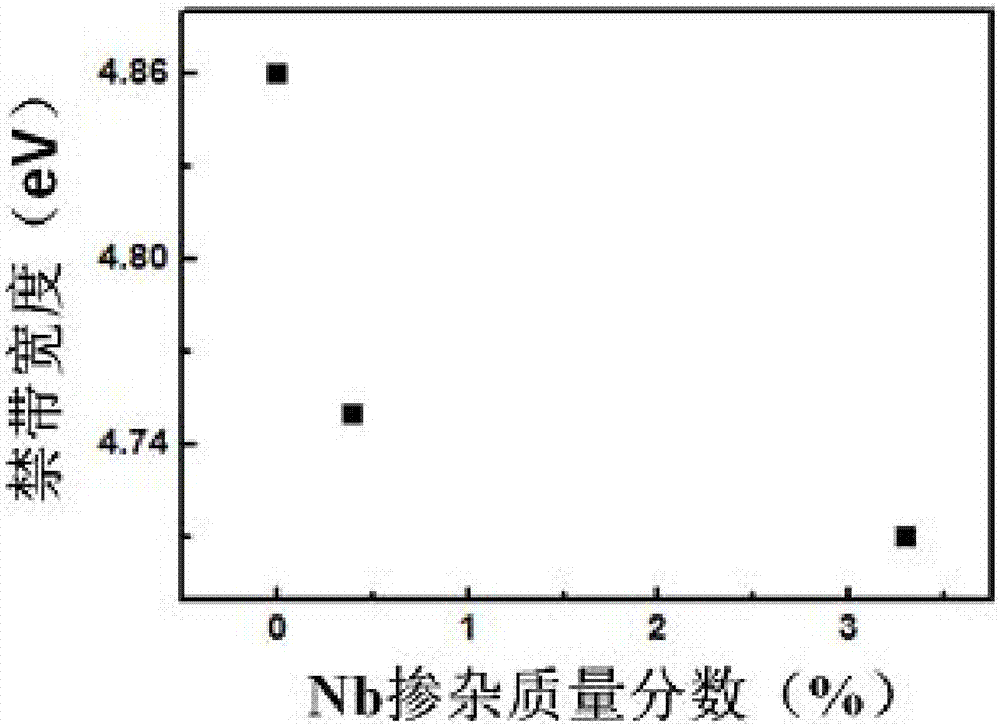

Method for tuning forbidden band width of Ga2O3 through Nb doping

A bandgap, ga2o3 technology, applied in the field of semiconductor materials, to achieve the effect of large bandgap tuning range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) A polished n-type silicon wafer is used as a substrate (with a resistivity of 2-4Ωcm and a thickness of 0.3mm). The substrates were ultrasonically cleaned with toluene, acetone, ethanol and deionized water for 15 min, and then dried in a glove box for 1 hour.

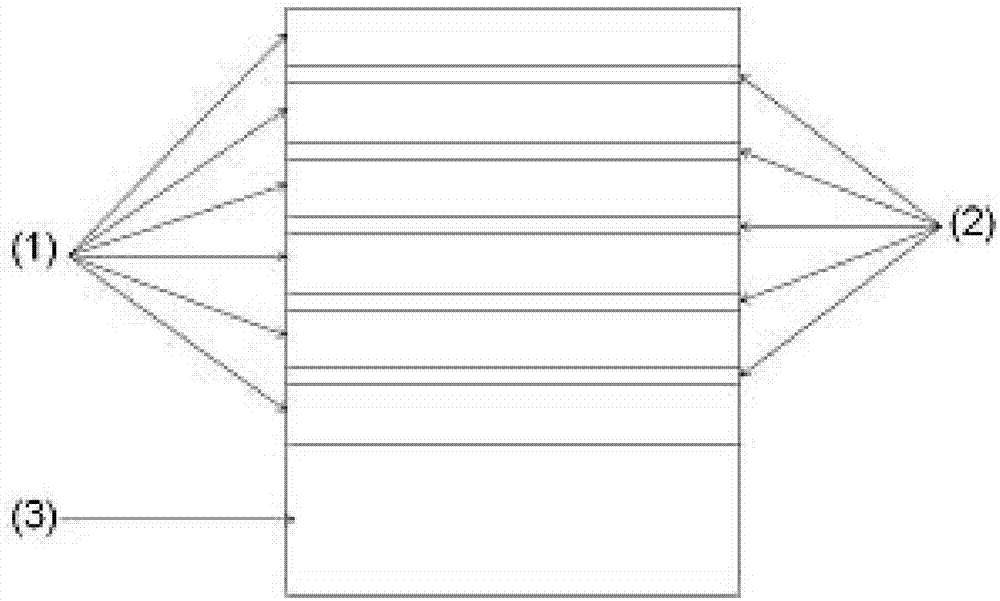

[0022] (2) Using radio frequency magnetron sputtering equipment to deposit Nb: Ga in layered growth 2 o 3 thin film materials, by controlling the Nb 2 o 5 and Ga 2 o 3 The sputtering time of the target controls the Nb doping dose. The pre-vacuum degree of the system is 1×10 -3 Below Pa. The film growth atmosphere is Ar, and the working pressure is 0.5Pa. Ga 2 o 3 and Nb 2 o 5 The sputtering power of the target is 80W, and the sputtering time is 300s, 10s alternately and 300s, 40s alternately, so as to obtain Nb:Ga with different Nb doping content 2 o 3 Thin film, wherein the thickness of the film is 250-260nm.

[0023] (3) The prepared Nb:Ga 2 o 3 The film samples were placed in a tube furnac...

Embodiment 2

[0026] (1) A polished n-type silicon wafer is used as a substrate (with a resistivity of 2-4Ωcm and a thickness of 0.3mm). The substrates were ultrasonically cleaned with toluene, acetone, ethanol and deionized water for 15 min, and then dried in a glove box for 1 hour.

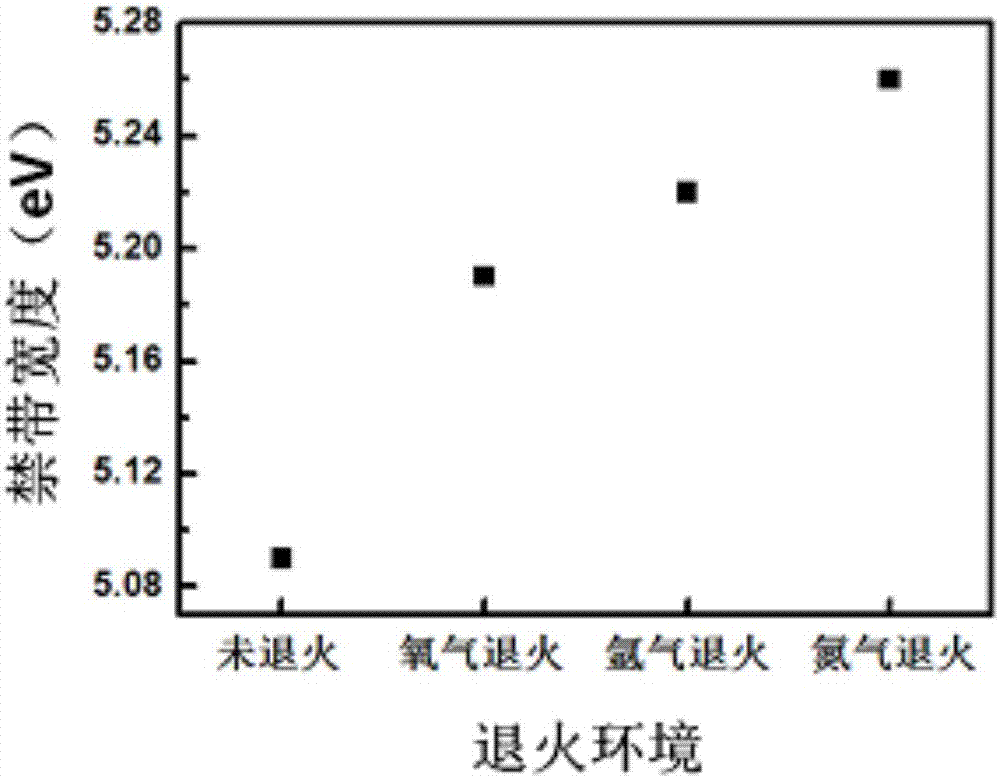

[0027] (2) Deposit Nb:Ga by co-sputtering using radio frequency magnetron sputtering equipment 2 o 3 film material. The pre-vacuum degree of the system is 1×10 -3 Below Pa. The film growth atmosphere is Ar, and the working pressure is 0.6Pa. Ga 2 o 3 and Nb 2 o 5 The sputtering power of the target is 80W, the sputtering time is 50min, and four Nb:Ga 2 o 3 Film samples.

[0028] (3) The prepared 3 Nb:Ga2 o 3 Thin film samples were placed in a tube furnace for Ar, O 2 and N 2 Atmosphere annealing. Use a mechanical pump to evacuate the air pressure in the tube furnace to below 1Pa, and introduce high-purity Ar (99.999%), O 2 (99.999%) or N 2 (99.999%). After that, the working pressure was mainta...

Embodiment 3

[0031] (1) A polished n-type silicon wafer is used as a substrate (with a resistivity of 2-4Ωcm and a thickness of 0.3mm). The substrates were ultrasonically cleaned with toluene, acetone, ethanol and deionized water for 15 min, and then dried in a glove box for 1 hour.

[0032] (2) Deposit Nb:Ga by co-sputtering using radio frequency magnetron sputtering equipment 2 o 3 film material. The pre-vacuum degree of the system is 1×10 -3 Below Pa. The film growth atmosphere is Ar, and the working pressure is 0.6Pa. Ga 2 o 3 and Nb 2 o 5 The sputtering power of the target is 80W. By controlling the co-sputtering coating time, multiple Nb:Ga with the same Nb doping content (doping mass percentage content is 1.5%) but different film thicknesses are obtained. 2 o 3 Film samples. Set the coating time to 20min, 30min, 40min, 60min respectively, and obtain four Nb:Ga films with thicknesses of 100nm, 150nm, 200nm and 300nm respectively. 2 o 3 Film samples.

[0033] (3) The pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com