Method for improving titanium-aluminum laminated composite material structure and improving mechanical performance

A layered composite material and mechanics technology, applied in the field of composite material preparation, can solve the problems of limitation, Ti room temperature plasticity, low toughness, etc., achieve performance optimization, good compatibility, and improve the effect of SiC fiber/matrix interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

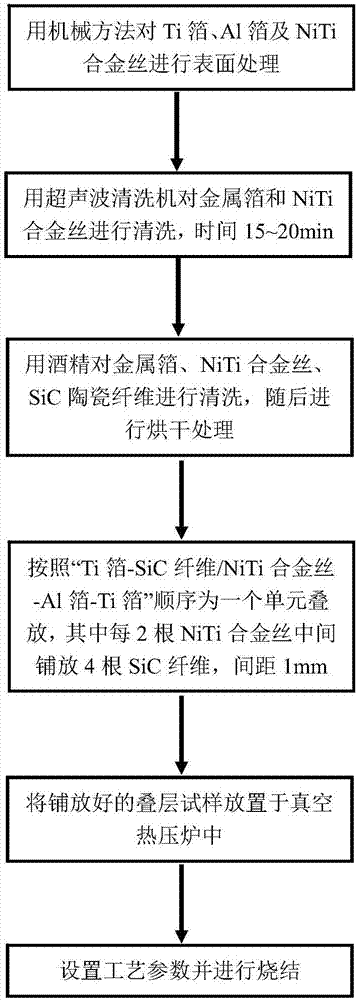

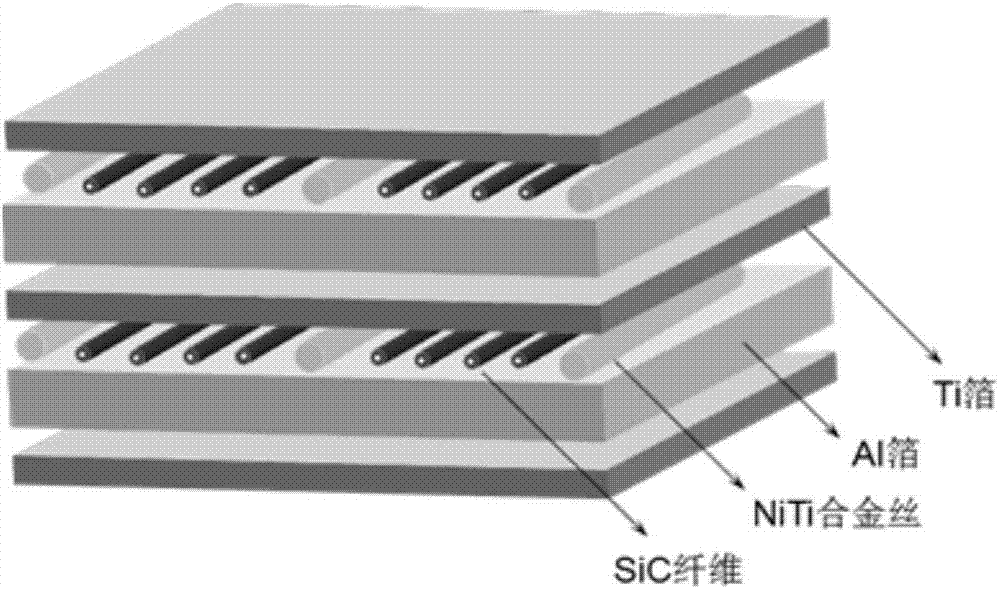

[0037] Cut the 0.5mm Al foil and 0.9mm Ti foil into a 100mm×100mm square foil, and cut the tungsten core SiC fiber (diameter ~ 100μm) and NiTi alloy wire (diameter 300μm) into a length of 100mm. First, the tungsten core SiC ceramic fiber is pretreated, the surface of the fiber is cleaned with alcohol to remove surface organic matter and impurities, and finally the fiber is dried. Use metallographic sandpaper to polish the surface of Ti foil, Al foil and NiTi alloy wire to remove the oxide layer, and then place it in ultrasonic cleaning (15-20min) at a temperature of 30°C to 40°C to remove the remaining oxide particles and impurities, and finally wash the metal foil and NiTi alloy wire with alcohol and then dry them. According to "Ti foil-SiC fiber / NiTi alloy wire-Al foil-Ti foil" as a unit, 4 SiC fibers are placed between every 2 NiTi alloy wires, with a distance of 1 mm, and 3 units are stacked, and the upper and lower outermost layers are uniform. For Ti foil.

[0038] Pla...

Embodiment 2

[0042] The pretreatment of raw material is with embodiment 1, and the technological parameter that adopts is: at 10 -3 Under Pa, raise the temperature to 600°C at a rate of 10°C / min and hold it for one hour. During the heat preservation process, the pressure is lower than 0.5MPa, then the temperature is slowly raised to 650°C and held for 4 hours, the pressure is 2MPa, and finally cooled to room temperature with the furnace.

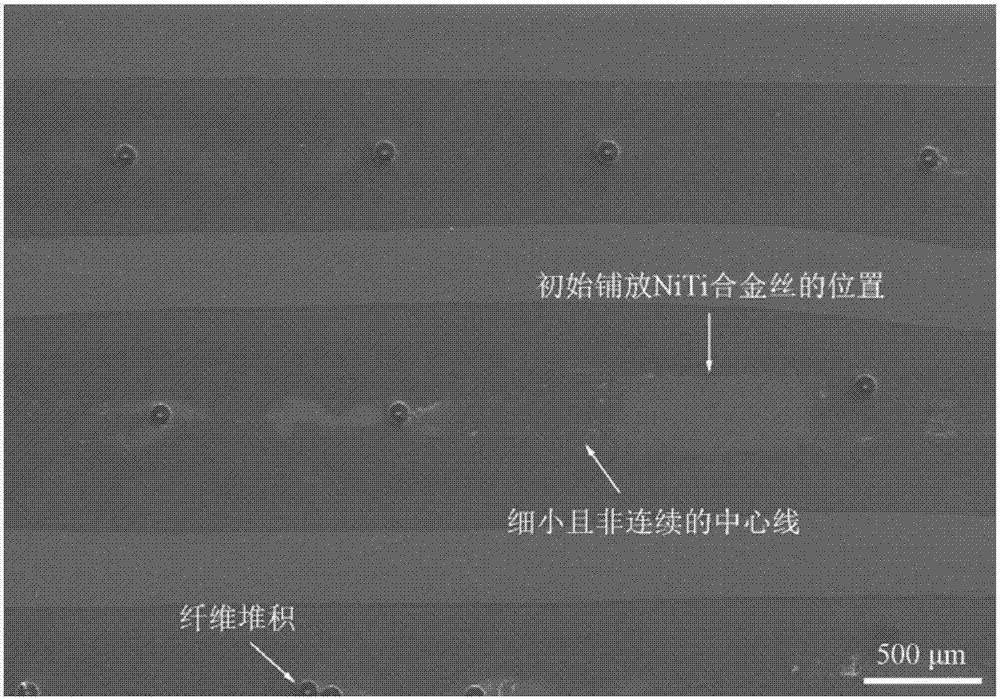

[0043] The sample layered structure SEM photomicrograph of present embodiment gained (see attached Figure 5 ), the magnification is 30 times, it can be seen that the NiTi alloy wire reacts fully with Al, and the long-term heat preservation makes it fully diffused. The intermetallic compound matrix is composed of light gray phase and dark gray phase, and the center line of the intermetallic compound layer is not observed , SiC fibers are uniformly distributed in the middle of the intermetallic compound matrix, and the micrograph of the fiber / matrix in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com