Preparation method of gel forming ultra-high-purity alumina ceramic lining disk trimming ring

An alumina ceramic, ultra-high-purity technology, applied in auxiliary molding equipment, molding indenters, ceramic molding machines, etc., can solve the problems of large equipment investment, high raw material cost, large environmental pollution, etc., and achieve high quality and simplified manufacturing. Process and improve the effect of pouring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

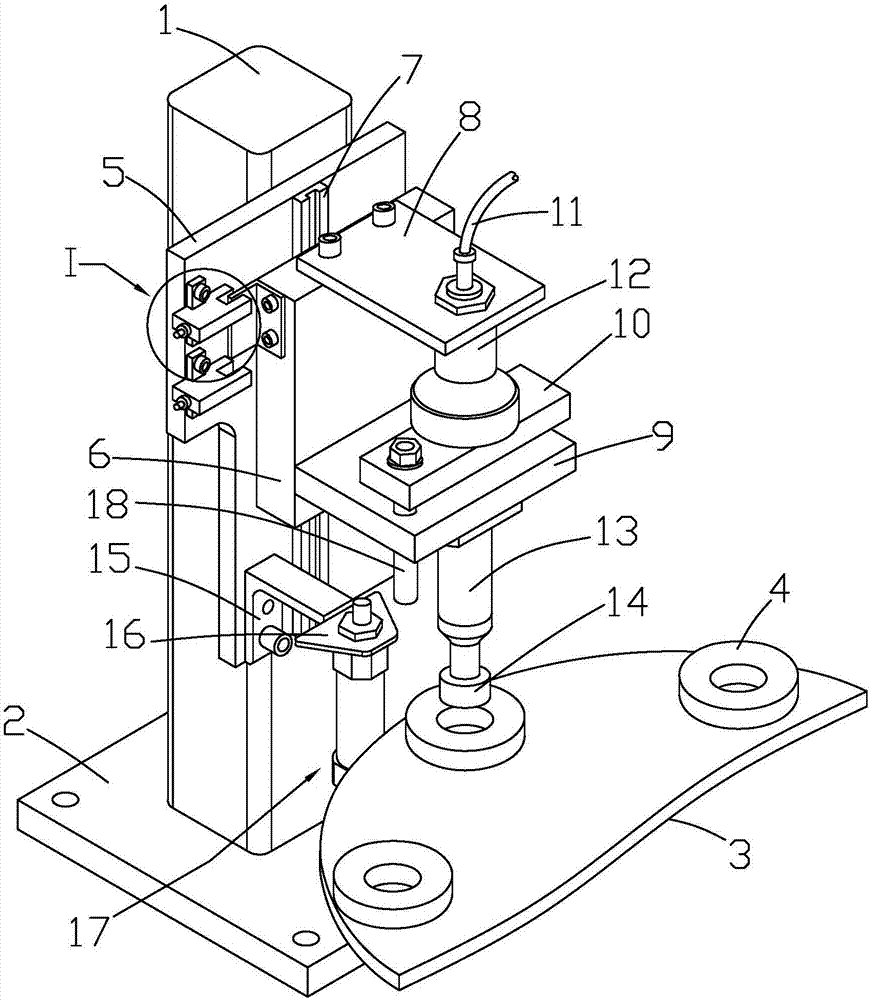

Image

Examples

Embodiment Construction

[0028] The invention discloses a method for preparing a gel-molded ultra-high-purity alumina ceramic liner dressing ring, comprising the following steps:

[0029] 1) First put the grinding body into the grinding jar, measure a certain amount of water, dispersant and crosslinking agent according to the formula, wherein the mass ratio of water, dispersant and crosslinking agent is 5:0.8:0.2, weigh the organic Monomer, dispersant and crosslinking agent are prepared into a premix solution in a grinding tank, and the pH value is adjusted between 8.0 and 9.5 with ammonia water and hydrochloric acid. The mass fraction of organic monomers in the ceramic powder is 4.2 to 4.8%. The agent accounts for 0.43-0.50% of the ceramic powder, the cross-linking agent is 5.1-5.5% of the organic monomer, the dispersant is sodium polyacrylate, and the cross-linking agent is methylene bisacrylic acid amine, polyacrylate, epoxy resin One of the organic monomers is acrylamide, the viscosity of the syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com