Preparation method of plug-in structure multi-level porous fau type zeolite molecular sieve

A zeolite molecular sieve and multi-level pore technology, which is applied in the directions of crystalline aluminosilicate zeolite and octahedral crystalline aluminosilicate zeolite, can solve the problems of unavoidable organic compounds, unfavorable industrial production, and reduce synthesis costs, and achieve large-scale Large-scale commercial production, reduced manufacturing process costs, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Add 0.5g of sodium hydroxide and 1.2g of sodium aluminate into 6.7g of deionized water, and stir until a clear solution;

[0025] (2) to the clear solution of step (1), slowly add 3.88g water glass (wherein the content of active ingredient is SiO 2 27.13 wt%, Na 2 (8.74wt%), stir evenly, ultrasonic, obtain uniform dilute colloid;

[0026] (3) Put the dilute colloid obtained in step (2) into a hydrothermal reaction kettle, and crystallize at a constant temperature of 75°C for 48h, wherein the molar ratio of the reaction mixture is Na 2 O: Al 2 o 3 :SiO2 2 :H 2 O=1.43:1.0:2.4:70.2;

[0027] (4) After the crystallization is completed, the solid product is filtered and washed, dried in a blast oven at 70°C for 24 hours, and then calcined at a constant temperature of 450°C in air for 5 hours (the heating rate is 1°C min -1 ), to obtain a "plug-in" structure hierarchical porous FAU type zeolite molecular sieve.

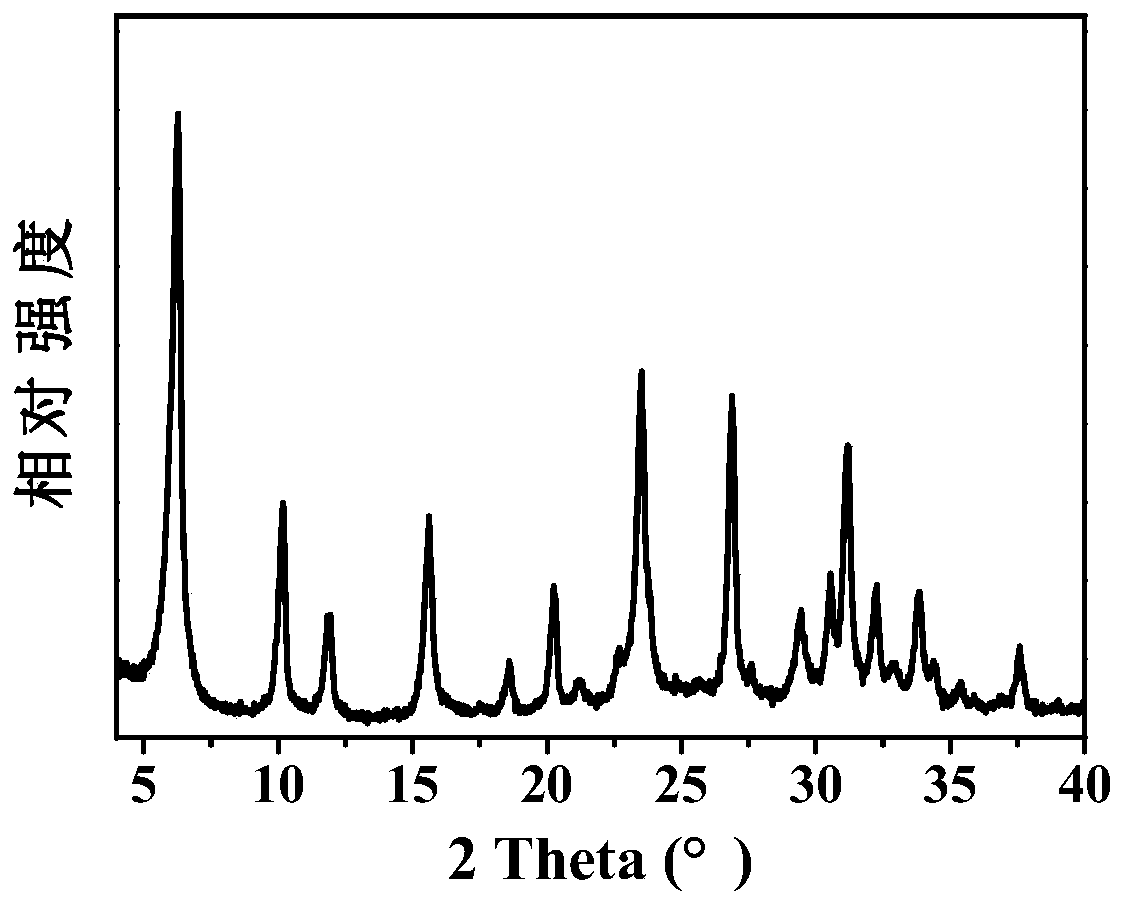

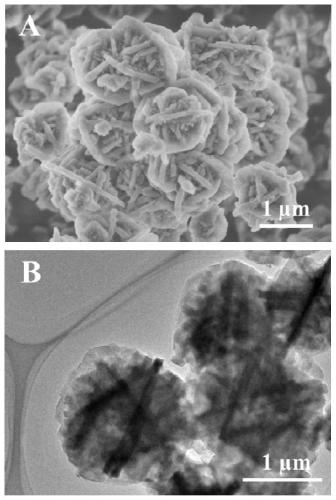

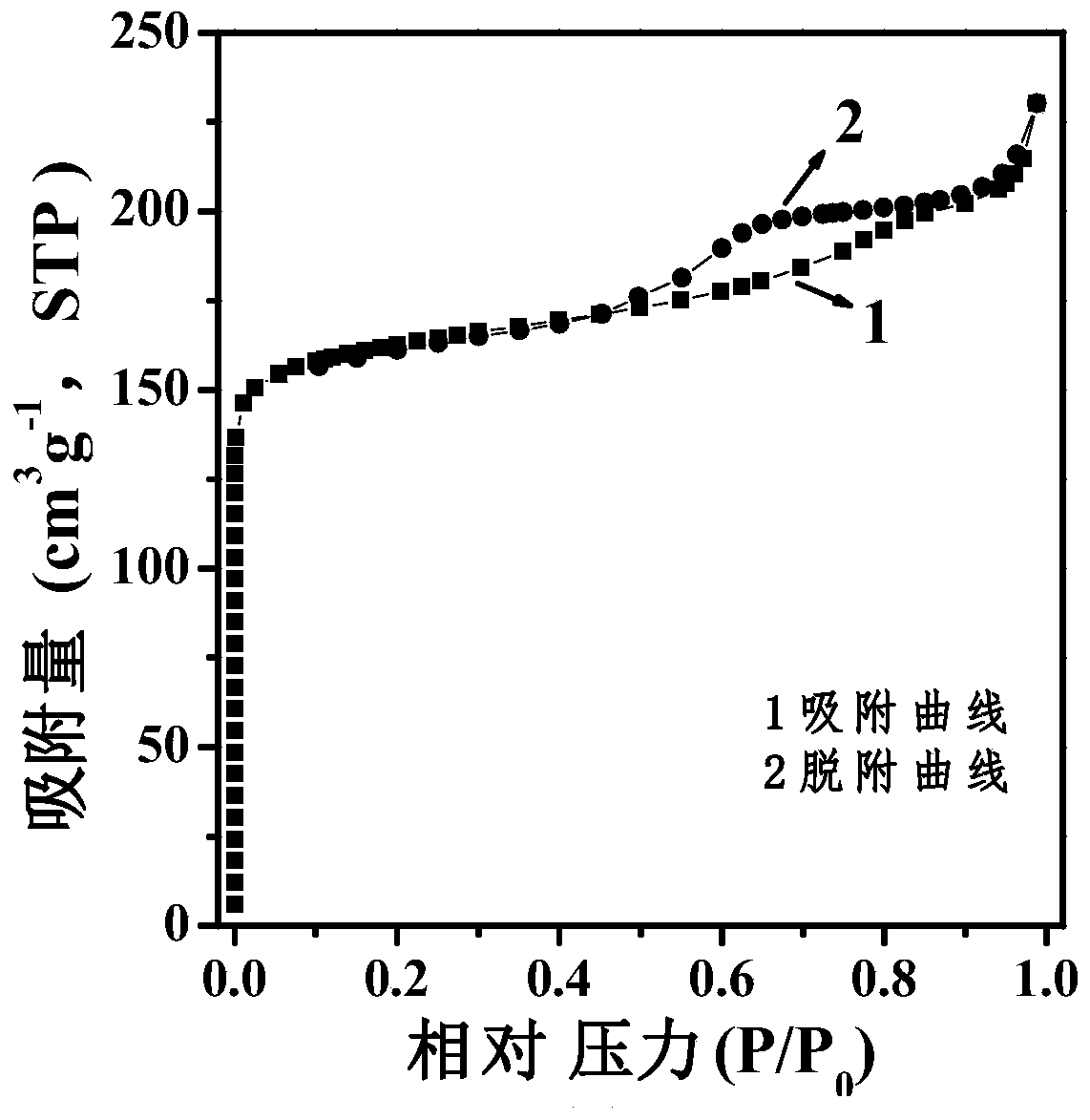

[0028] The characterization and analysis of the "pl...

Embodiment 2

[0034] (1) Add 0.5g of sodium hydroxide and 1.2g of sodium aluminate into 6.7g of deionized water, and stir until a clear solution;

[0035] (2) to the clear solution of step (1), slowly add 3.88g water glass (wherein the content of active ingredient is SiO 2 27.13 wt%, Na 2 (8.74wt%), stir evenly, ultrasonic, obtain uniform dilute colloid;

[0036] (3) Put the dilute colloid obtained in step (2) into a hydrothermal reaction kettle, crystallize at a constant temperature of 60°C for 72h, wherein the molar ratio of the reaction mixture is Na 2 O: Al 2 o 3 :SiO2 2 :H 2 O=1.43:1.0:2.4:70.2;

[0037] (4) After the crystallization is completed, the solid product is suction filtered, washed, dried in a blast oven at 70°C under normal pressure for 24 hours, and then calcined at a constant temperature of 500°C in air for 4 hours (the heating rate is 1°C min -1 ), obtain " plug-in card " type multi-stage hole FAU type molecular sieve 2.2g, productive rate is 18% (product accounts...

Embodiment 3

[0040] (1) Add 0.5g sodium hydroxide and 1.2g sodium aluminate to 4.7g deionized water, and stir until a clear solution;

[0041] (2) to the clear solution of step (1), slowly add 3.88g water glass (wherein the content of active ingredient is SiO 2 27.13 wt%, Na 2 (8.74wt%), stir evenly, ultrasonic, obtain uniform dilute colloid;

[0042] (3) Put the dilute colloid obtained in step (2) into a hydrothermal reaction kettle, and crystallize at a constant temperature of 75°C for 48h, wherein the molar ratio of the reaction mixture is Na 2 O: Al 2 o 3 :SiO2 2 :H 2 O=1.43:1.0:2.4:54.8;

[0043] (4) After the crystallization is completed, the solid product is suction filtered, washed, dried in a blast oven at 70°C under normal pressure for 24 hours, and then calcined at a constant temperature of 450°C in air for 4 hours (the heating rate is 1°C min -1 ) to obtain 2.1 g of "plug-in card" type multi-stage porous FAU molecular sieves, with a productive rate of 20.4% (the mass rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com