Laser additive texturing method

A laser material addition and texturing technology, which is applied in the field of material surface processing, can solve the problems of unsatisfactory textured appearance and excessive roll roughness attenuation, so as to improve the surface topography structure, enhance wear resistance and roughness The effect of retention and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

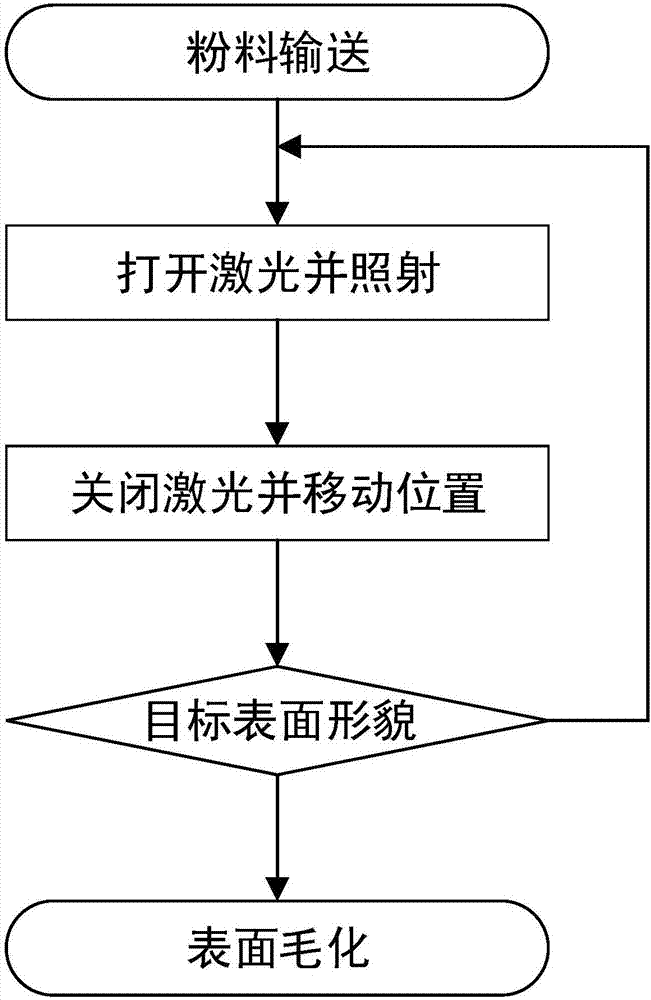

Method used

Image

Examples

Embodiment 1

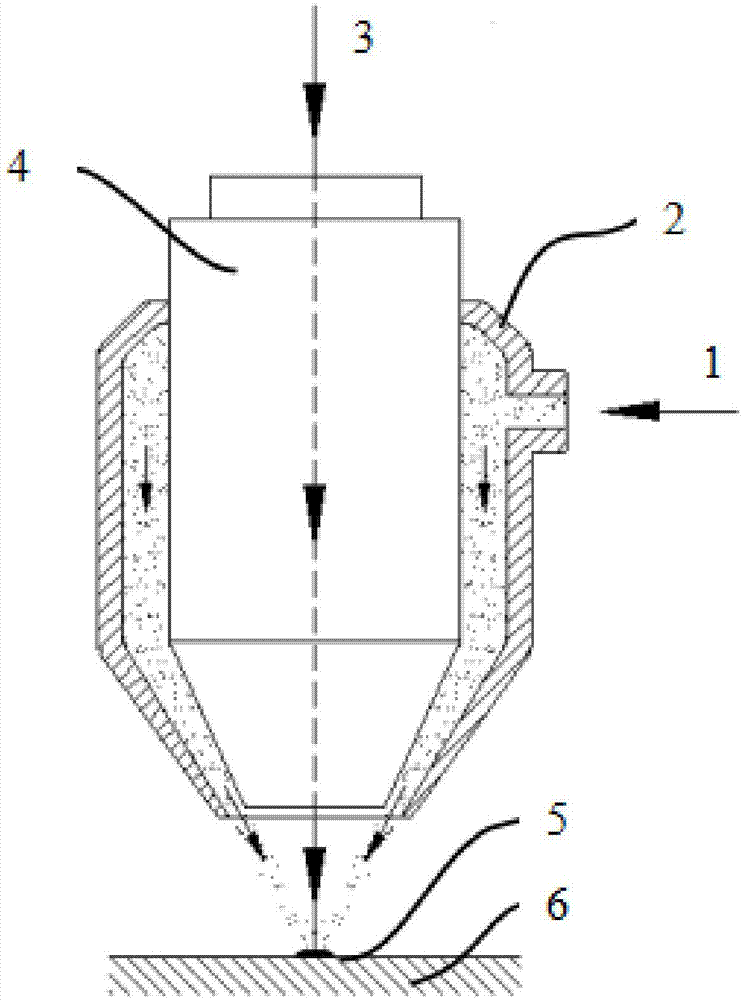

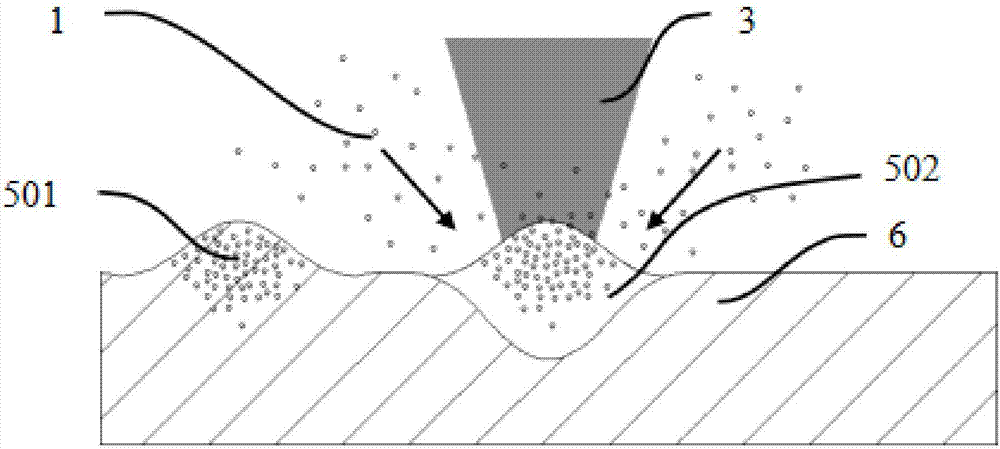

[0047] See attached figure 2, the selected powder 1 is WC, Co composite powder, the mass fraction ratio is 9:1, and the particle size is about 0.1-0.3 μm. The laser head 4 and the powder feeding nozzle 2 have a coaxial structure. The powder 1 is transported to the laser head 4 through the auxiliary nitrogen gas, and then sprayed out from the conical nozzle around the laser head 4, and gathers at the laser focus. The minimum convergence diameter It is about 100μm, the injection speed of the powder is about 15m / s, and the injection amount is about 2.5g / min. The power of the laser is 200W, the pulse frequency is 22kHz, and the spot diameter after focusing is about 80μm. Base material 6 is a common Cr5 forged roll. The focal length of the laser focusing lens is 250mm, and its focal point after focusing is consistent with the point where the powder material converges. The roll is installed on the machine tool to rotate at a speed of 250rpm. The laser head is installed on the to...

Embodiment 2

[0051] See attached Figure 4 , The selected powder is WC, Cr, Fe mixed powder, the mass fraction ratio is 6:3:1, and the particle size is about 0.2-2 μm. The laser head and the powder feeding nozzle are of paraxial structure, the minimum diameter of the powder converging is 80 μm, and other parameters are consistent with the embodiment.

[0052] According to the measurement, the diameter of the textured boss obtained under this parameter is between 80 and 120 μm, the height of the textured boss is between 5 and 8 μm, the surface roughness of the texturized roll is about 2.01 μm, and the textured point The hardness of the roll is about HV920, and the hardness of the roll surface in the untextured area is about HV320.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com