A test device and method for dynamic bending resistance of automobile side pillars hitting key parts

A test device, a technology on the side of the car, which is applied to the design of the test method for the dynamic bending resistance of auto parts, and the field of the test device for the dynamic bending resistance of the key parts of the automobile side pillar, which can solve the problems of high resource consumption and long development cycle. , to achieve the effect of low test cost, low cost and less interference factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

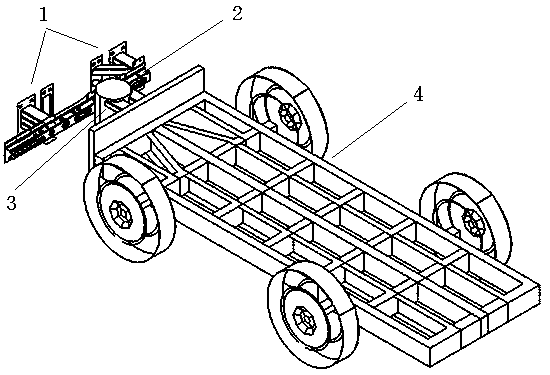

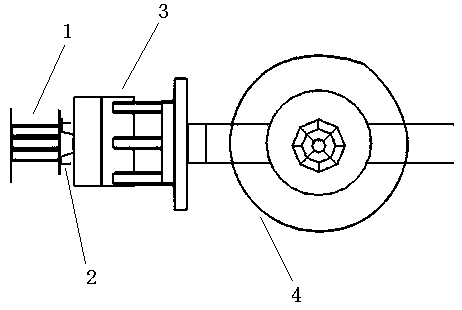

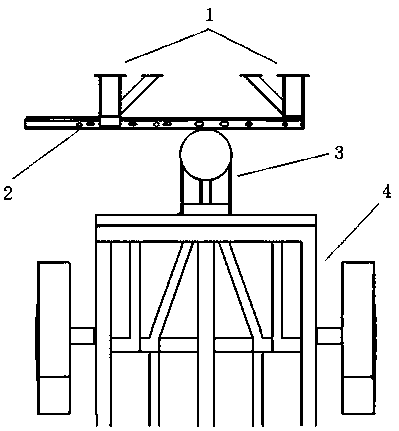

[0032] Such as figure 1 , 2, 3, the test device of the dynamic bending performance of the automobile side pillar bump key part of the present invention comprises a bracket assembly 1 installed on the rigid wall for fixing the test piece 2 and for applying dynamic impact force to the test piece 2 collision structure. Bracket assembly 1 includes a left bracket and a right bracket. The left bracket consists of a left bracket body and a left bracket connecting part arranged at the front end of the left bracket body. The right bracket consists of a right bracket body and a right bracket connecting part arranged at the front end of the right bracket body. The collision structure includes the traction trolley 4 and the collision part 3 arranged at the front end of the traction trolley 4 . The dynamic impact test is performed on the specimen 2 fixed on the bracket assembly 1 through the collision structure, which can simulate the bending deformation of the specimen 2 under high-spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com