Energy-saving recycling tail gas treatment equipment

An exhaust gas treatment and energy-saving technology, which is applied in the field of exhaust gas treatment equipment and energy-saving recycling exhaust gas treatment equipment, can solve the problems of limited application occasions, waste, unusable heat sources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

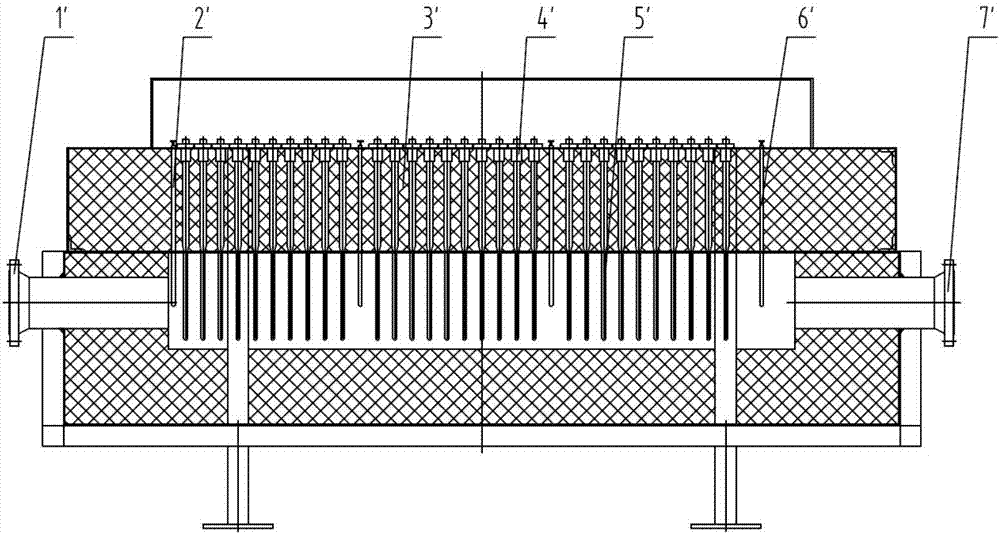

[0023] The basic structure of the energy-saving recycling tail gas treatment equipment in this embodiment is as follows: Figure 2 to Figure 5 As shown, it is mainly composed of a tunnel-type electric heating furnace body 1 , a shell-and-tube exhaust gas heat exchanger 7 and a shell-and-tube exhaust gas boiler 26 . The inlet of the shell-type exhaust gas heat exchanger 7 as the exhaust gas inlet 19 to be treated passes through a tube pass composed of a set of exhaust gas heat exchange tubes 9 and passes through the 180° elbow 5, and then connects to the tunnel-type electric heating furnace body through the expansion and reduction tube 4 The inlet of 2 is heated at a lower flow rate in the furnace body. The outlet of the tunnel-type electric heating furnace body 1 passes through the reduced-diameter variable-diameter pipe and the 90° elbow 5, and then passes through the shell side of the shell-and-tube exhaust gas heat exchanger 9 to connect a group of steam heat exchange tubes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com