Automatic control system for water flow

An automatic control system and water flow technology, applied in control/regulation systems, non-electric variable control, simultaneous control of multiple variables, etc., can solve problems such as water waste, water control is not automatic, other energy waste, etc., to achieve easy installation , to ensure the stability, the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

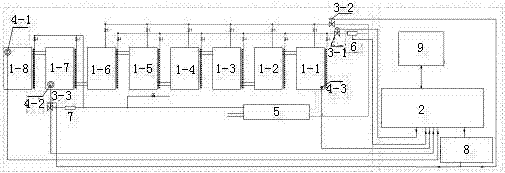

[0015] refer to figure 1 , the present invention relates to a water flow automatic control system, comprising several water tanks and a microcomputer 2, said several water tanks are provided with control valves for water flow and sensors for detecting parameters in the water tanks, said sensors are connected to the input terminals of the microcomputer 2, and said The output end of the microcomputer 2 is connected with the control valve.

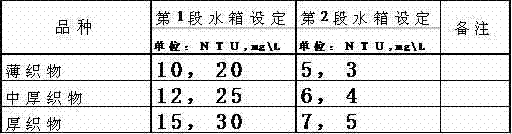

[0016] Above-mentioned several water tanks comprise 8 (several) water tanks 1-1, 1-2, 1-3, 1-4, 1-5, 1-6, 1-7, 1-8 connected successively, wherein No. 8 (actual One of them is determined according to the process) Water tanks 1-8 are equipped with ultrasonic sensors 4-1 and No. 7 to detect the amount of dirt on the cloth surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com