Lysinibacillus and application thereof in degrading of zearalenone

A technology of lysine bacillus and zearalenone, which is applied in the field of lysine bacillus and its application in the degradation of zearalenone, which can solve difficult large-scale production, loss of nutrients, and ZEA removal Problems such as unstable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Isolation and Identification of Bacterial Strains

[0032] 1. Isolation of strains

[0033] (1) In a sterile workbench, take out the intestinal contents of the chicken and mix them evenly, weigh 0.25-0.5g and add them to 10mL LB liquid medium containing 20ppm ZEA at a final concentration for acclimation and cultivation on a shaking table, the shaking table speed is 200r / min, the shaker temperature was 37°C, and the acclimatization time was 96h.

[0034] (2) Take the above-mentioned acclimatized bacterial solution in the aseptic operating table and inoculate it into 10 mL of LB liquid medium containing 20 ppm ZEA in a volume ratio of 1% and inoculate it on a shaking table for acclimation and cultivation. 37°C, the acclimatization time is 96h. Repeat this cycle 2-3 times.

[0035] (3) Dilute the bacterial solution after the last acclimatization culture with sterile physiological saline, then spread it on the LB medium plate, and cultivate it at 37°C for 24 ...

Embodiment 2

[0043] Example 2: Application of Bacillus lysinica ZJ-2016-1 culture solution in degrading zearalenone

[0044] 1. Culture and activation of Bacillus lysinica ZJ-2016-1

[0045] Lysinibacillus macroides ZJ-2016-1 was inoculated in liquid LB medium, cultured by shaking at a temperature of 37°C and a rotation speed of 200r / min (rotation radius: 20mm) for 24h, and the culture products were collected It is the ZJ-2016-1 culture medium, which is used for the subsequent zearalenone degradation experiment.

[0046] 2. Degradation of zearalenone by Bacillus lysinica ZJ-2016-1 culture solution

[0047] (1) Preparation of Zearalenone Solution

[0048] 10 mg of zearalenone standard substance (Sigma-Aldrich, product number Z2125) was dissolved in 50 mL of chromatographically pure methanol to obtain a zearalenone solution with a concentration of 200 ppm.

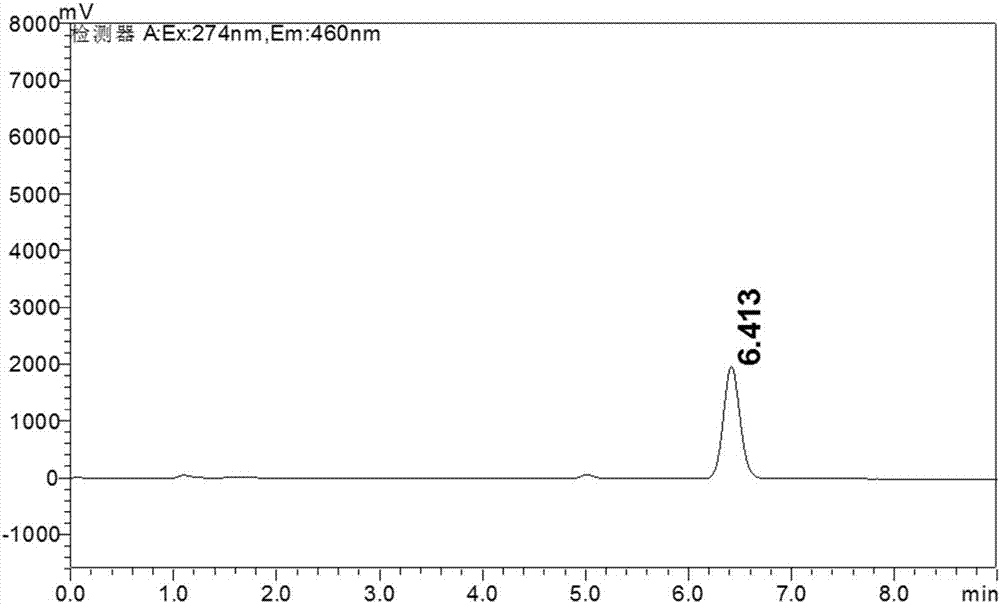

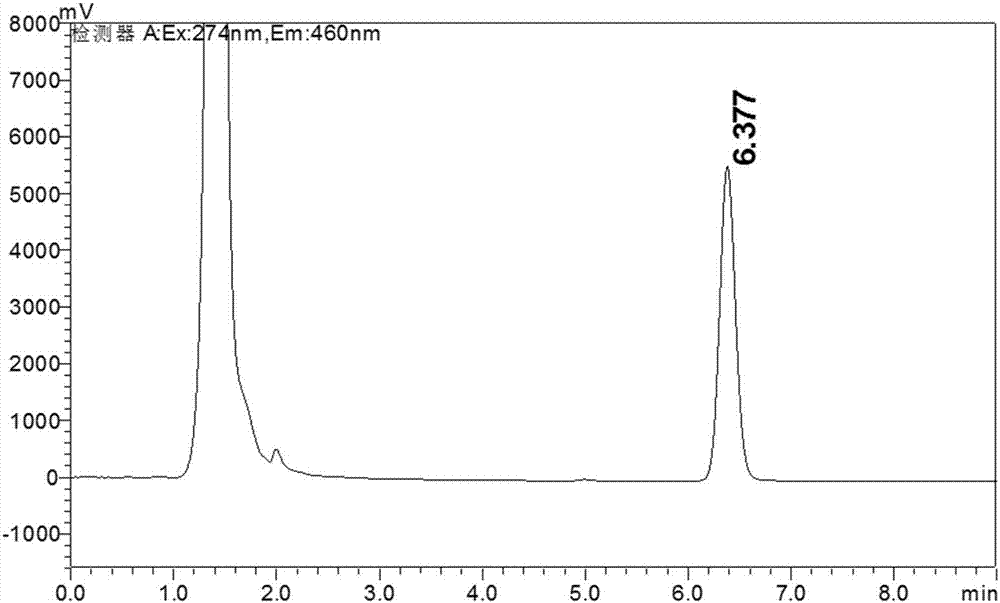

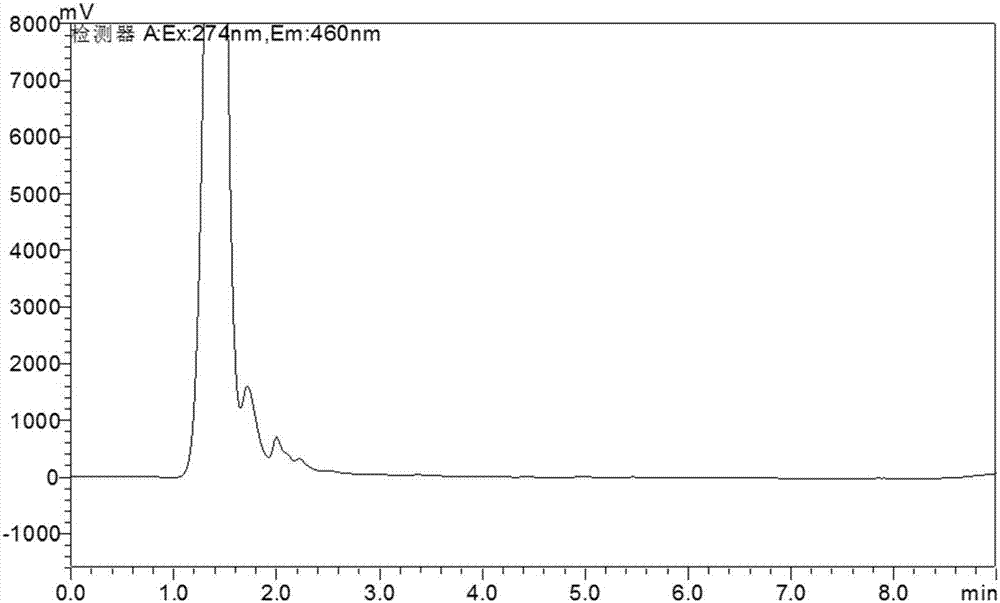

[0049] (2) Degradation of zearalenone

[0050] Experimental group: Take 1 mL of zearalenone solution with a concentration of 200 pp...

Embodiment 3

[0058] Example 3: Degradation of zearalenone in corn feed by Bacillus lysinica ZJ-2016-1 culture solution

[0059] 1. Degradation of zearalenone in corn feed by Bacillus lysinica ZJ-2016-1 culture solution

[0060] Weigh 450g of corn feed, add zearalenone standard substance (Sigma-Aldrich, product number Z2125) to make the final concentration 10ppm, mix well, divide into 9 parts on average, do three different treatments, each treatment set 3 repetitions, the first one was added with 50mL sterile water (blank group), the second one was added with 50mL sterilized LB culture medium (control group), and the third one was added with a cell concentration of 10 7 cell / mL ZJ-2016-1 culture solution (experimental group), and then placed in a 37°C constant temperature incubator for 48h.

[0061] 2. Detection of zearalenone

[0062] The preparation of PBS buffer solution (0.01mol / L): mix 8g NaCl, 1.44g Na 2 HPO 4 , 0.24g KH 2 PO 4 1. Dissolve 0.2g KCl in 800mL deionized water, adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com