An antistatic protective film

An antistatic and protective film technology, applied in conductive coatings, coatings, etc., can solve the problems of loss of antistatic performance, antistatic coating peeling, stains, etc., to achieve good antistatic effect, stable antistatic performance, The effect of reducing surface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Prepare acrylate resin with 10g methyl methacrylate, 5g sodium p-styrene sulfonate, 5g ethyl acrylate, 5g acrylic acid, 2.5g hydroxyethyl acrylate, 2.5g diacetone acrylamide, the preparation method of acrylate resin and CN103554340B In the same way, polymerize at 70°C for 4 hours, then lower the temperature of the synthesized acrylate resin to 50°C, add 2.25g of poly-3,4-dioxyethylenethiophene and continue stirring for 1.5 hours before discharging to obtain conductive acrylic acid ester resin.

[0028] Take the above-mentioned 15g conductive acrylate resin and 2.5g methyl etherified hexamethylolmelamine formaldehyde resin, 2.5g BYK348, 20g isopropanol and 60g deionized water, and mix them uniformly to obtain an antistatic coating solution. Coated on optical grade polyester film and dried to obtain an antistatic protective film.

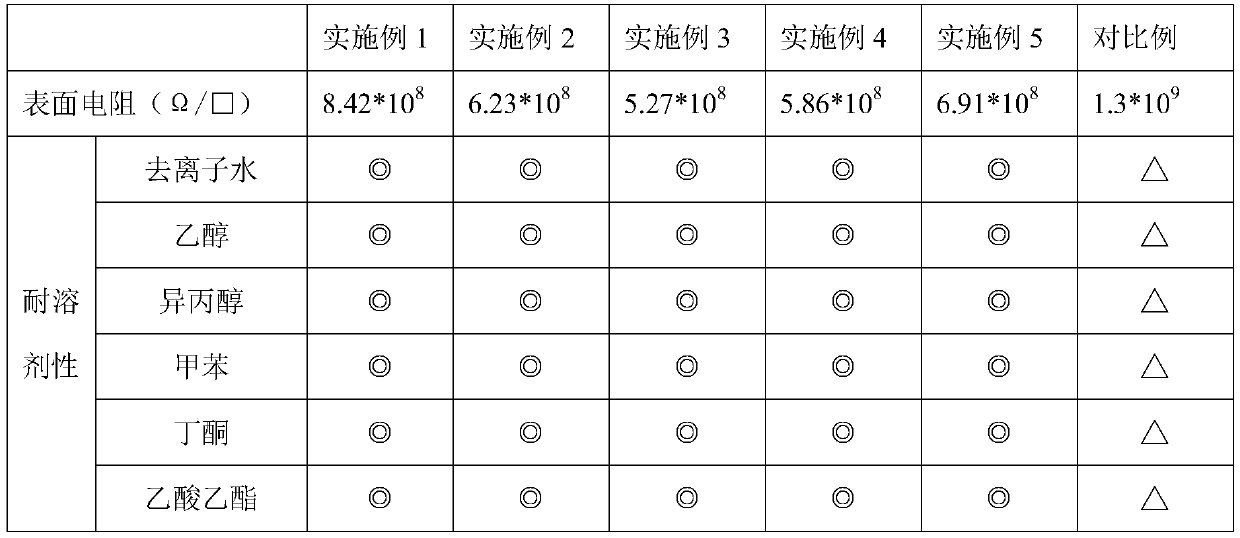

[0029] The performance test results are shown in Table 1.

Embodiment 2

[0031] Prepare acrylate resin with 25g vinyl acetate, 55g butyl acrylate, 10g sodium p-styrenesulfonate, 5g methacrylic acid, 10g hydroxypropyl acrylate, 5g diacetone acrylamide, the preparation method of acrylate resin is the same as CN103554340B, Polymerize at 75°C for 3.5 hours, then lower the temperature of the synthesized acrylate resin to 50°C, add 0.8g polythiophene-3-[2-(2-methoxyethoxy)ethoxy]-2,5 -Dibase, 3.9g poly-3,4-dioxyethylenethiophene, 0.8g poly-3-thiophene acetic acid were stirred and kept for 1 hour, and then discharged to obtain conductive acrylate resin.

[0032] Weigh the above 35g conductive acrylate resin, 0.4g trimethylolmelamine formaldehyde resin, 0.4g methylolated hexamethylolmelamine formaldehyde resin, 1.5g BYK333, 1g BYK380N, 40g isopropanol and 20g deionized water, mix well Finally, an antistatic coating solution is obtained, and the coating solution is coated on an optical-grade polyester film, and dried to obtain an antistatic protective film....

Embodiment 3

[0034] Acrylate resin is prepared with 10g methyl methacrylate, 45g butyl acrylate, 25g isooctyl acrylate, 15 p-styrene sodium sulfonate, 7g acrylic acid, 15g hydroxyethyl acrylate, 8g hydroxypropyl acrylate. The preparation method is the same as that of CN103554340 B, polymerize at 80°C for 3 hours, then lower the temperature of the synthesized acrylate resin to 45°C, add 2.7g of polythiophene-3-[2-(2-methoxyethoxy)ethyl Oxy]-2,5-diyl, 8.9g of poly-3,4-dioxyethylenethiophene, and 0.9g of poly-3-thiopheneacetic acid were stirred and kept for 1 hour, and then discharged to obtain a conductive acrylate resin.

[0035] Weigh the above-mentioned 20g conductive acrylate resin, 0.1g methylolated hexamethylolmelamine formaldehyde resin, 0.1g trimethylolmelamine formaldehyde resin, 1g BYK348, 0.5g BYK380N, 10g isopropanol, 5g butanol, 5g ethylene glycol Alcohol and 40g of deionized water were mixed evenly to obtain an antistatic coating solution, which was coated on an optical-grade p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com