Oil-resistant and anti-aging acrylate rubber and preparation method thereof

An acrylate, anti-aging technology, applied in the field of rubber, can solve the problems of erosion of polymer chains and loss of working ability of rubber products, and achieve high chemical stability, excellent anti-aging, oil resistance and strong oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

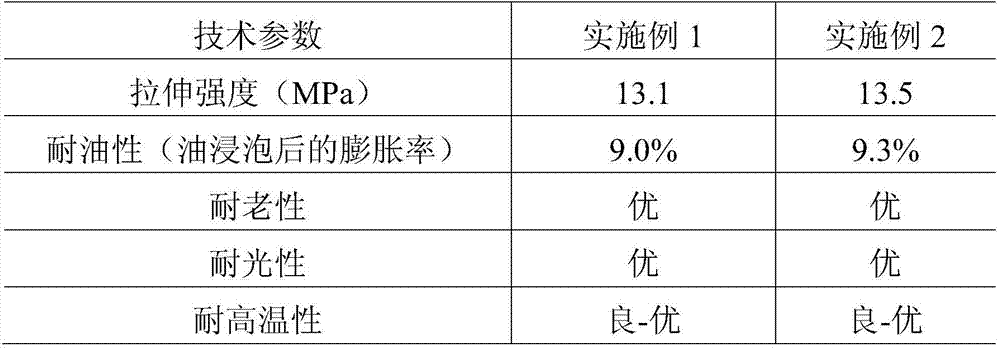

Examples

Embodiment 1

[0016] An oil-resistant and anti-aging acrylate rubber, consisting of the following raw materials in parts by weight:

[0017] 75 parts of acrylate rubber, 28 parts of natural rubber, 6 parts of polyvinyl alcohol, 3 parts of nano-zinc oxide, 8 parts of fumed silica, 6 parts of carbon black N550, N-cyclohexyl-N'-phenyl-p-phenylenediamine 2 parts, dibutyl phthalate 4 parts, sulfur 2 parts, coumarone 1 part.

[0018] The preparation method of the above-mentioned oil-resistant and aging-resistant acrylate rubber comprises the following steps:

[0019] 1) Predetermined ratio of polyvinyl alcohol, nano-zinc oxide, fumed silica, carbon black N550, N-cyclohexyl-N'-phenyl-p-phenylenediamine, dibutyl phthalate, sulfur and coumarin After pre-mixed intercalation treatment, put it in the reactor and stir for 35 minutes, and then discharge the mixture, the stirring speed is 70rpm / min, and the stirring temperature is 80°C;

[0020] 2) Slowly add a predetermined proportion of acrylate rubbe...

Embodiment 2

[0023] An oil-resistant and anti-aging acrylate rubber, consisting of the following raw materials in parts by weight:

[0024] 80 parts of acrylate rubber, 30 parts of natural rubber, 7 parts of polyvinyl alcohol, 3 parts of nano-zinc oxide, 10 parts of fumed silica, 8 parts of carbon black N550, N,N'-di(2-naphthyl)-p-phenylene 2 parts of diamine, 5 parts of dibutyl phthalate, 2 parts of sulfur, 1.5 parts of liquid rubber.

[0025] The preparation method of the above-mentioned oil-resistant and aging-resistant acrylate rubber comprises the following steps:

[0026] 1) Predetermined ratio of polyvinyl alcohol, nano-zinc oxide, fumed silica, carbon black N550, N,N'-di(2-naphthyl)-p-phenylenediamine, dibutyl phthalate, sulfur and After the liquid rubber is pre-mixed and intercalated, it is placed in the reactor and stirred for 35 minutes before being discharged, which is the mixture. The stirring speed is 70rpm / min, and the stirring temperature is 80°C;

[0027] 2) Slowly add a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com