High-molecular-weight soluble elementary sulfur/terpene copolymer, and preparation method and application of same

A technology of elemental sulfur and copolymer, applied in the field of soluble elemental sulfur/terpene copolymer and its preparation, can solve the problems of low molecular weight and application limitation, and achieve the effects of high reaction yield, avoidance of waste and easy experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

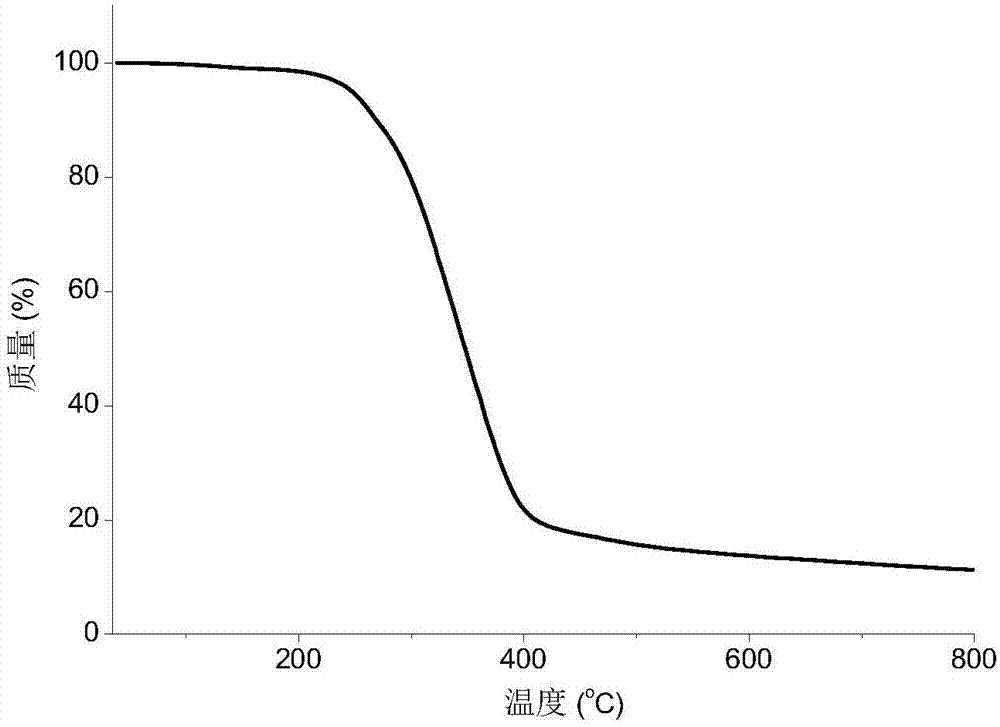

[0040] A method for preparing elemental sulfur / terpene copolymer includes the following steps:

[0041] ⑴ Put 28g of sublimed sulfur into a 150ml four-necked flask equipped with mechanical stirring, condenser and thermometer inserted, add tetramethyl disulfide, and heat under nitrogen atmosphere until the sulfur is completely melted, add 10g pinene, and add 700r / Stir at a speed of about 10 minutes until it is uniform;

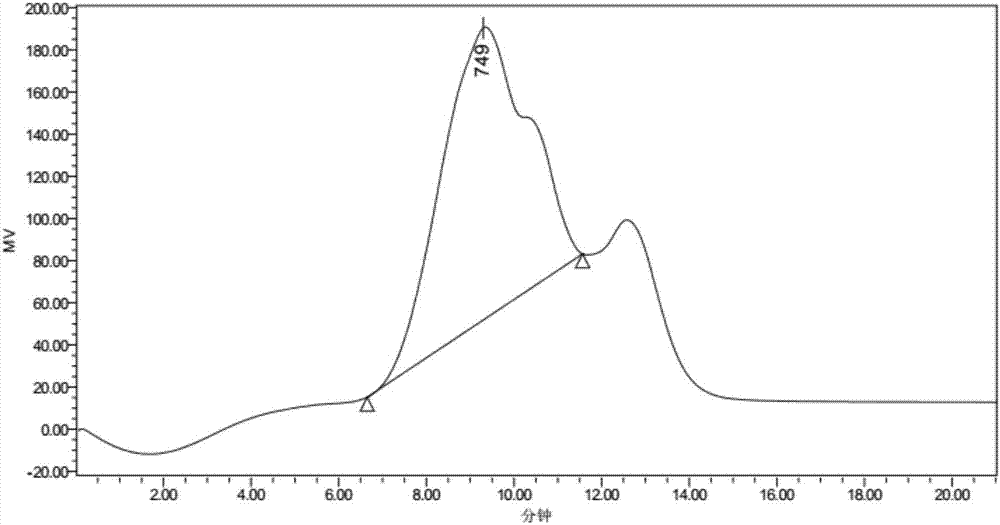

[0042] (2) Raise the uniformly mixed reaction system in step (1) to 155°C to carry out the polymerization reaction. After 2 hours, the product is subjected to vacuum distillation for 20 minutes to remove unreacted monomers, and then rapidly cooled and solidified with liquid nitrogen to obtain a dark red block. The solid polymerized sulfur crude product; the crude product is dissolved in tetrahydrofuran, filtered and centrifuged to remove insoluble impurities; then the solvent is removed by rotary evaporation, and then placed in a vacuum drying oven at 40°C for 12 h...

Embodiment 2

[0047] A method for preparing elemental sulfur / terpene copolymer includes the following steps:

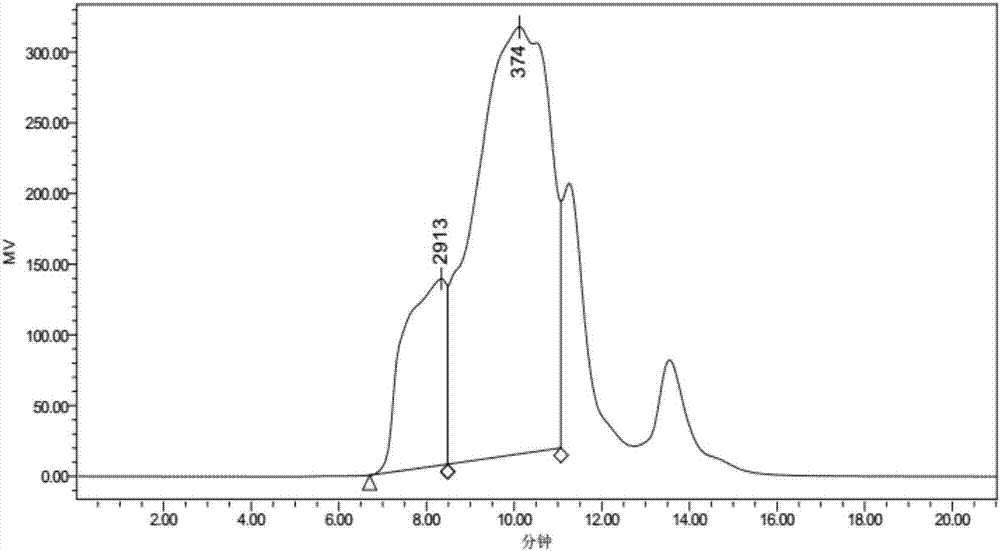

[0048] ⑴ Put 28g of sublimed sulfur into a 150ml four-necked flask equipped with mechanical stirring, condenser and thermometer inserted, add ammonium persulfate, and heat it under nitrogen atmosphere until the sulfur is completely melted, then add 10g of pinene, and add 10g of pinene at 700r / min. Stir at a speed of about 10min to uniform;

[0049] (2) Raise the uniformly mixed reaction system in step (1) to 155°C to carry out the polymerization reaction. After 2 hours, the product is subjected to vacuum distillation for 20 minutes to remove unreacted monomers, and then rapidly cooled and solidified with liquid nitrogen to obtain a dark red block. The solid polymerized sulfur crude product; the crude product is dissolved in tetrahydrofuran, filtered and centrifuged to remove insoluble impurities; then the solvent is removed by rotary evaporation, and then placed in a vacuum drying oven ...

Embodiment 3

[0052] A method for preparing elemental sulfur / terpene copolymer includes the following steps:

[0053] ⑴ Put 28g of sublimed sulfur into a 150ml four-necked flask equipped with mechanical stirring, condenser and thermometer inserted, add tetramethyl disulfide, and heat under nitrogen atmosphere until the sulfur is completely melted, add 14g pinene, and add 700r / Stir at a speed of about 10 minutes until it is uniform;

[0054] (2) Raise the uniformly mixed reaction system in step (1) to 155°C to carry out the polymerization reaction. After 2 hours, the product is subjected to vacuum distillation for 20 minutes to remove unreacted monomers, and then rapidly cooled and solidified with liquid nitrogen to obtain a dark red block. The solid polymerized sulfur crude product; the crude product is dissolved in tetrahydrofuran, filtered and centrifuged to remove insoluble impurities; then the solvent is removed by rotary evaporation, and then placed in a vacuum drying oven at 40°C for 12 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com