Green preparation method of manganese dioxide

A manganese dioxide, green technology, applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of environmental protection and energy saving, and achieve the effect of mild conditions, easy operation and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0056] The preparation of potassium permanganate solution: the potassium permanganate consumption in the above-mentioned embodiment 1 is changed to 0.6360g, other conditions are constant, carry out experiment;

[0057] The preparation of manganese dioxide: change the amount of pollen in the above-mentioned embodiment 1 to 0.3g, and keep other conditions unchanged, carry out the experiment, and the black intermediate powder product obtained is designated as sample 2.

Embodiment 3

[0059] The preparation of potassium permanganate solution: the potassium permanganate consumption in the above-mentioned embodiment 1 is changed to 0.64g, other conditions are constant, carry out experiment;

[0060] Preparation of manganese dioxide: change the amount of pollen in the above-mentioned embodiment 1 to 0.4g, and keep other conditions constant, carry out the experiment, and the obtained black intermediate powder product is designated as sample 3.

[0061] 3.4 Embodiment 4

[0062] The preparation of potassium permanganate solution: the potassium permanganate consumption in the above-mentioned embodiment 1 is changed to 0.6360g, other conditions are constant, carry out experiment;

[0063] Preparation of manganese dioxide: the reaction temperature in the above-mentioned embodiment 1 was adjusted to 40° C., and other conditions were kept constant, and the experiment was carried out, and the obtained black intermediate powder product was designated as sample 4.

[006...

Embodiment 7

[0070] A part of sample 2 obtained in Example 2 was calcined, and the temperature was raised to 500° C. in a muffle furnace at a rate of 5° C. / min for 3.5 hours. After cooling, it was ground to obtain a black final product, which was designated as sample 7.

[0071] 3.8 Embodiment 8

[0072] A part of sample 2 obtained in Example 2 was calcined, and the temperature was raised to 600° C. in a muffle furnace at a rate of 5° C. / min for 2.5 hours. After cooling, it was ground to obtain a black final product, which was designated as sample 8.

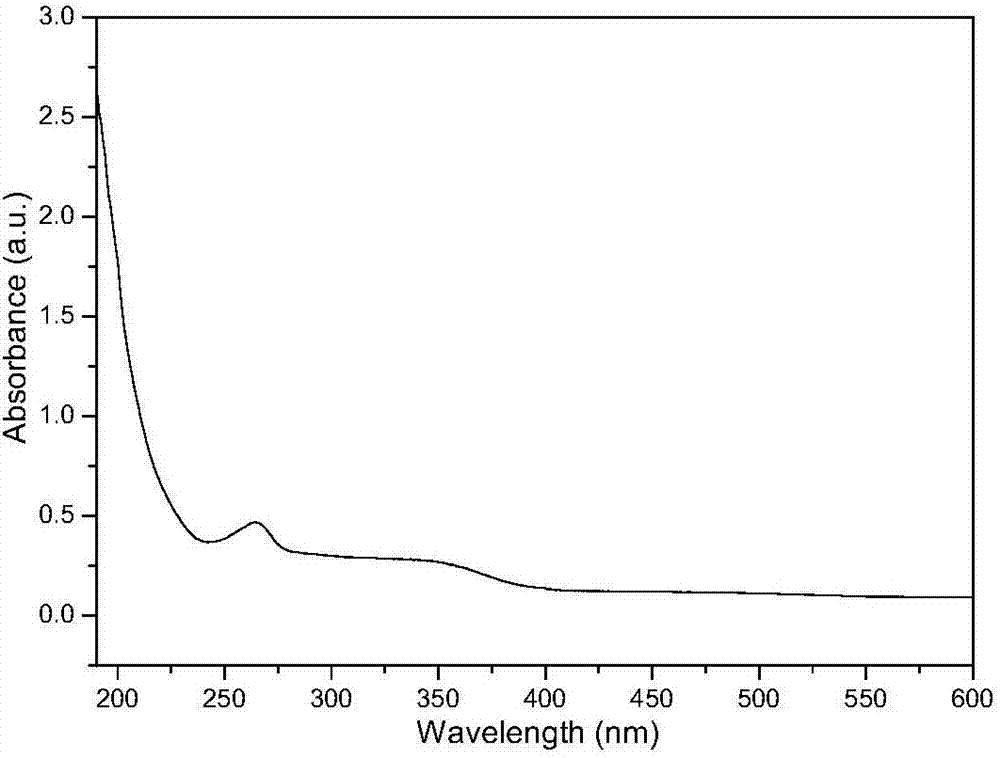

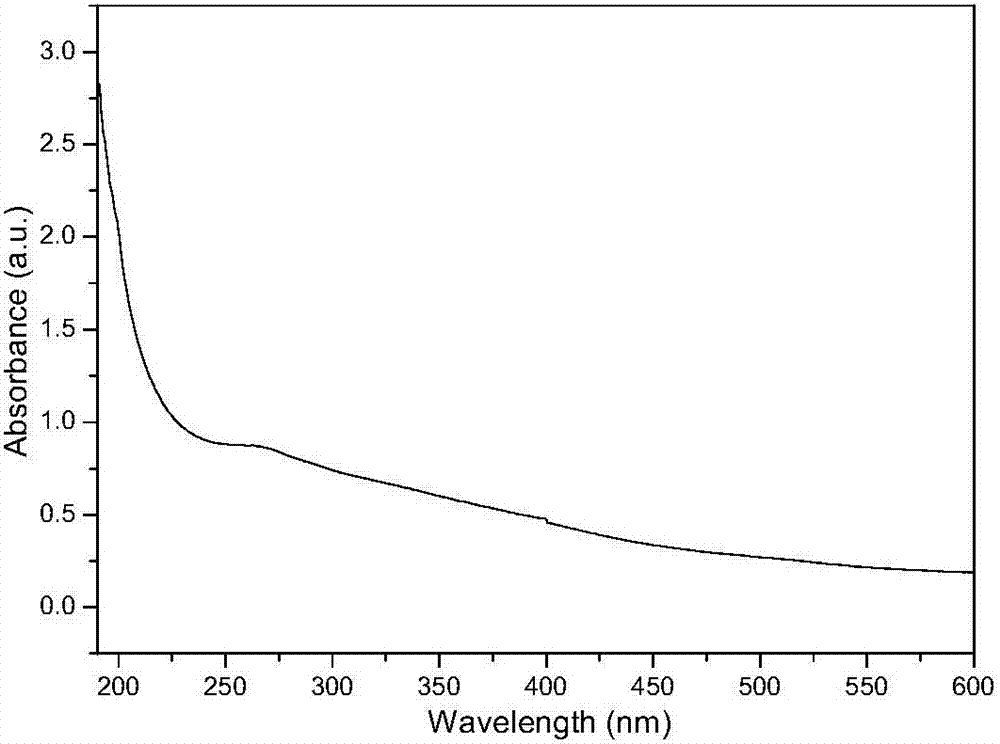

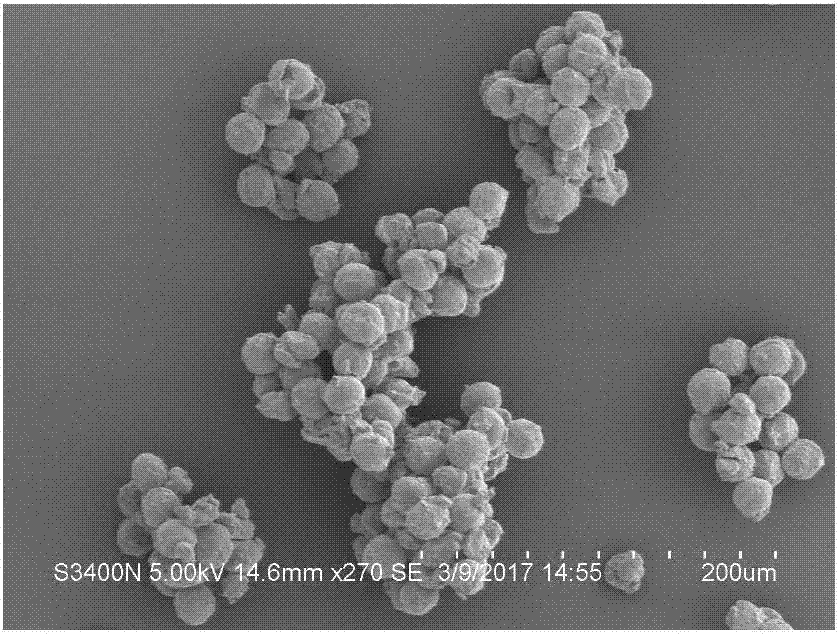

[0073] The samples obtained in the above examples were verified by ultraviolet spectrum and scanning electron microscope tests respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com