All-plant and additive-free synthetic surfactant cleansing product

A surfactant-free technology, applied in the field of skin care products, can solve the problems of expanding skin capillaries, not being green and safe, poor foam performance, etc., and achieve the effect of less dosage, low cost and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

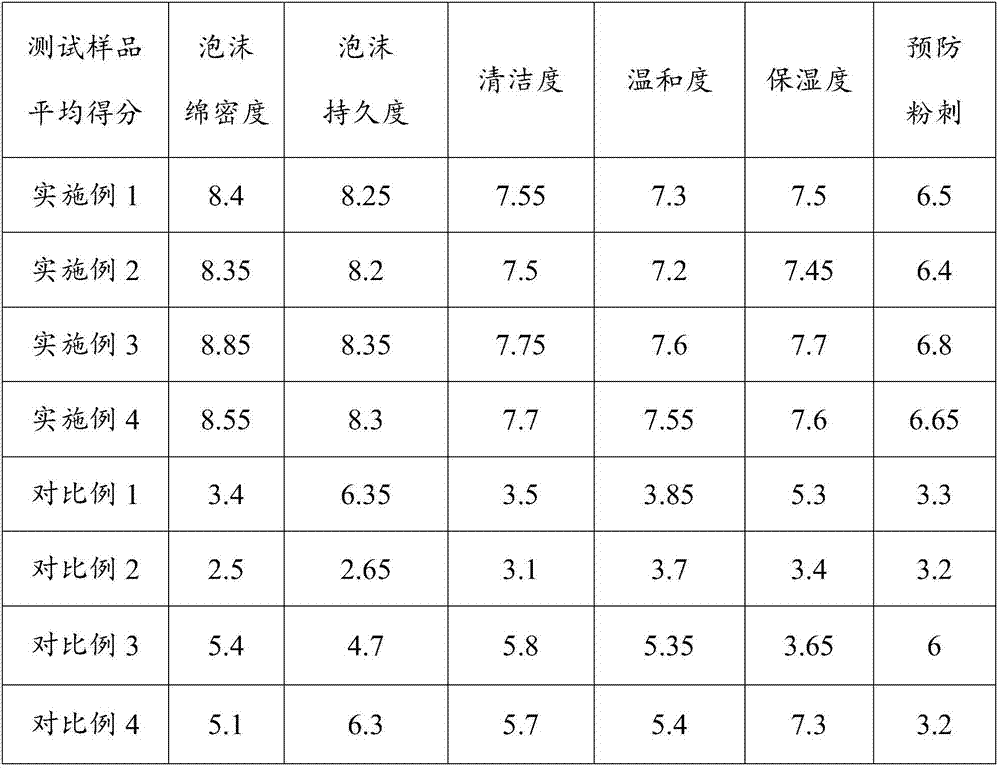

Examples

Embodiment 1

[0026] The present invention provides a whole plant cleansing product without adding synthetic surfactants. Based on the total mass of 100g, it contains 30g of Sapinberry extract, 23.5g of foam stabilizer, 0.8g of plant preservative, and the balance is water.

[0027] Wherein: the foam stabilizer is composed of hydrogenated starch hydrolyzate and glycosyl trehalose according to the mass ratio of 0.5:1.2; :2:4 composition.

[0028] The described Sapinberry extract is obtained through the following steps in turn: Weigh 40 parts by weight of Sapinberry pericarp, place it in 150 parts by weight of plant fermentation liquid and soak for 20 days, soak the Soapberry pericarp at 0 ℃ low-temperature vacuum drying, ultrafinely pulverize the frozen Sapindus chinensis, add 60mL of 20% ethanol (that is, the ratio of solid to liquid is 1:60) to each gram of Sapindus chinensis fine powder, ultrasonically extract at 25°C for 20min, and ultrasonically The frequency is 2.0 MHz, filtered throug...

Embodiment 2

[0031] The present invention provides a whole plant cleansing product without adding synthetic surfactants, based on 100 g of total mass, 20 g of sapinsia chinensis extract, 14.5 g of foam stabilizer, 1.2 g of plant preservative, and the balance is water.

[0032] Wherein: the foam stabilizer is composed of hydrogenated starch hydrolyzate and glycosyl trehalose according to the mass ratio of 0.5:1.6; 3:2:4 composition.

[0033] The described Sapinberry extract is obtained through the following steps in turn: Weigh 40 parts by weight of Sapinberry pericarp, place it in 280 parts by weight of plant fermentation liquid and soak it for 20 days, soak the Soapberry pericarp in 4 ℃ low-temperature vacuum drying, ultrafinely pulverize the frozen Sapindus chinensis, add 60mL of 80% ethanol (that is, the ratio of material to liquid is 1:60) to each gram of Sapindus chinensis fine powder, ultrasonically extract at 25°C for 20min, and ultrasonically extract The frequency is 2.0MHz, filte...

Embodiment 3

[0036] The present invention provides a whole plant cleansing product without adding synthetic surfactants. Based on the total mass of 100g, it contains 5g of Sapindus chinensis extract, 15g of foam stabilizer, 1g of plant preservative, and the balance is water.

[0037] Wherein: the foam stabilizer is composed of hydrogenated starch hydrolyzate and glycosyl trehalose according to the mass ratio of 0.5:1.4; It is composed according to the mass ratio of 3:2:3.

[0038] The described Sapinberry extract is obtained through the following steps in turn: Weigh 30 parts by weight of Sapinberry pericarp, place it in 200 parts by weight of plant fermentation broth and soak for 20 days, soak the Sapinberry pericarp in 2 ℃ low-temperature vacuum drying, the frozen Sapindus superfine powder, add 50mL of 50% ethanol (that is, the ratio of solid to liquid is 1:50) to each gram of Sapindus fine powder, ultrasonically extract at 25℃ for 20min, ultrasonically The frequency is 1.8MHz, filter w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com