Icing-resisting road and construction method thereof

An anti-icing and road technology, applied in the direction of roads, roads, coagulation pavement paved on site, etc., can solve the problems of asphalt and cement concrete denudation, great influence of environmental temperature, and inability to remove cleanly, to prevent the road surface. Freezing, simple and easy construction methods, and the effect of improving work timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

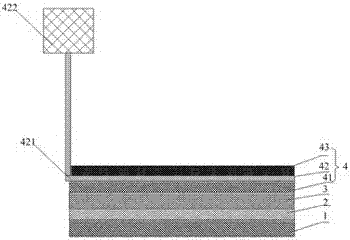

[0033] Such as figure 1 As shown, the anti-icing road provided in Example 1 includes a graded crushed stone layer 1, a cement stabilized base layer 2, a stabilized crushed stone layer 3 and an asphalt concrete layer 4 distributed sequentially from bottom to top, and the asphalt concrete layer It includes an asphalt concrete lower layer 41 , an oil pipe layer 42 and an asphalt concrete upper layer 43 distributed sequentially from bottom to top. The oil pipe layer includes evenly laid and connected oil pipes 421. In this embodiment, the oil pipes 421 are distributed in an S shape, and the laying distance L of the oil pipes 421 is 50 cm. The oil pipe 421 is connected to the solar heat absorbing panel 422 outside the anti-icing road. In practical application, the solar heat absorbing plate 422 can be installed on the street lamp, and the oil pipe 422 is connected to the solar heat absorbing plate 422 installed on the street lamp according to the distribution of the street lamp an...

Embodiment 2

[0045] The structure of the anti-icing asphalt concrete layer that present embodiment 2 provides is identical with embodiment 1, can refer to figure 1, including a graded crushed stone layer 1, a cement stabilized base layer 2, a stabilized crushed stone layer 3 and an asphalt concrete layer 4 distributed sequentially from bottom to top, and the asphalt concrete layer includes an asphalt concrete lower layer 41, oil pipe layer 42 and Asphalt concrete upper layer 43. The oil pipe layer includes evenly laid and connected oil pipes 421 . In this embodiment, the oil pipes 421 are distributed in an S shape, and the laying interval L of the oil pipes 421 is 60 cm. The oil pipe 421 is connected to the solar heat absorbing panel 422 outside the anti-icing road. In practical application, the solar heat absorbing plate 422 can be installed on the street lamp, and the oil pipe 422 is connected to the solar heat absorbing plate 422 installed on the street lamp according to the distributi...

Embodiment 3

[0057] The structure of the anti-icing asphalt concrete layer that present embodiment 3 provides is identical with embodiment 1, can refer to figure 1 , including a graded crushed stone layer 1, a cement stabilized base layer 2, a stabilized crushed stone layer 3 and an asphalt concrete layer 4 distributed sequentially from bottom to top, and the asphalt concrete layer includes an asphalt concrete lower layer 41, oil pipe layer 42 and Asphalt concrete upper layer 43. The oil pipe layer includes evenly laid and connected oil pipes 421 . In this embodiment, the oil pipes 421 are distributed in parallel, and the laying interval L of the oil pipes 421 is 60 cm. The oil pipe 421 is connected to the solar heat absorbing panel 422 outside the anti-icing road. In practical application, the solar heat absorbing plate 422 can be installed on the street lamp, and the oil pipe 422 is connected to the solar heat absorbing plate 422 installed on the street lamp according to the distributio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com