High-wear-resistant polypropylene composite material used for automobile interior trim and preparation method of polypropylene composite material

A technology for automobile interior and composite materials, which is applied in the field of high wear-resistant polypropylene composite materials for automobile interiors and its preparation, can solve problems such as affecting the aesthetics of automobiles, poor wear resistance, and easy occurrence of damage, and achieves the maintenance of mechanical properties. Good performance, good wear resistance and basically unchanged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

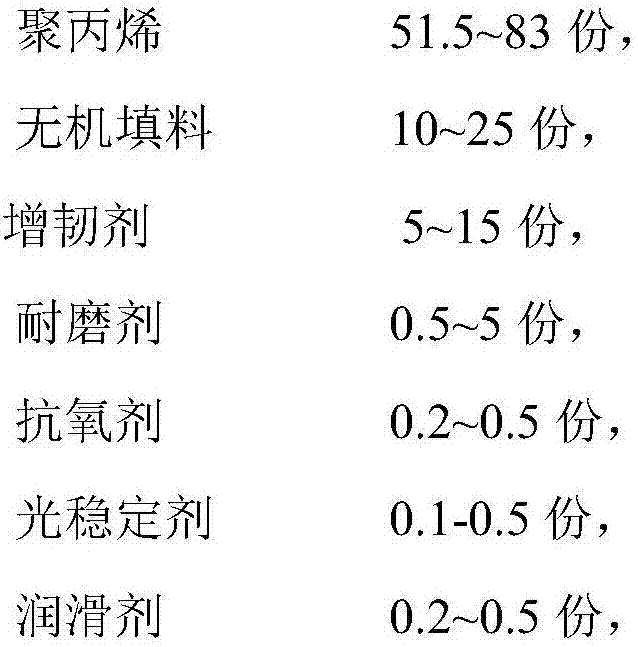

Method used

Image

Examples

Embodiment Construction

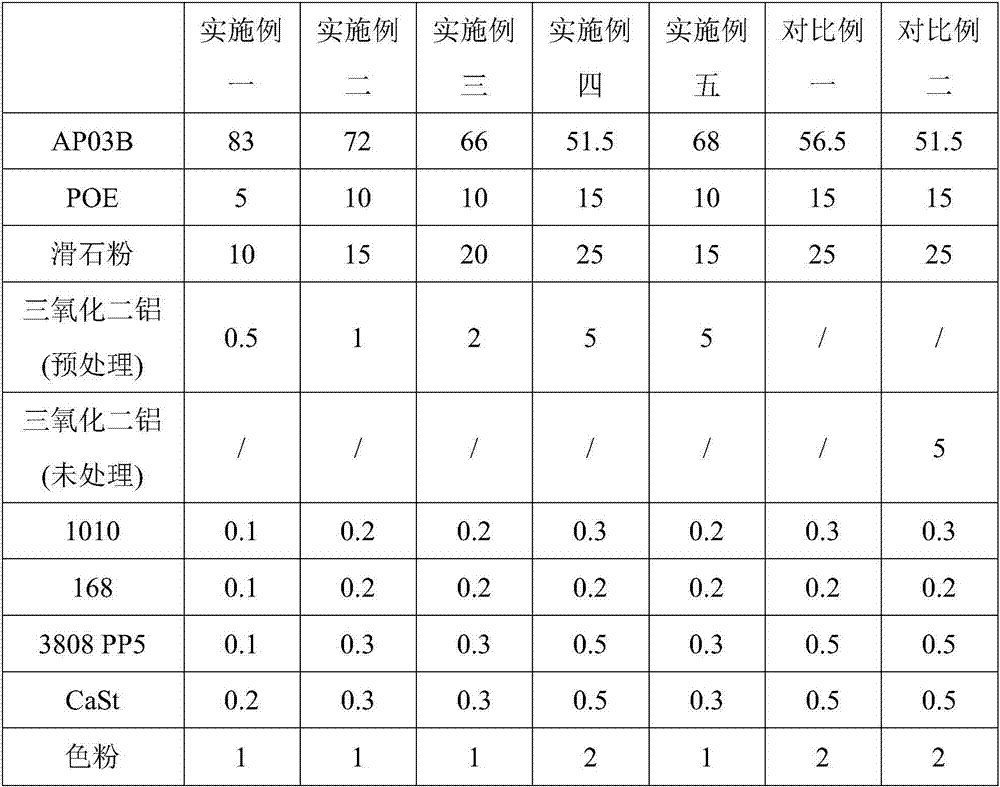

[0024] In conjunction with the examples, the present invention is further described in detail: in the examples and comparative examples, the polypropylene used is produced by ExxonMobil, and the specific brand is AP03B. The inorganic filler used is 3000 mesh talcum powder. The toughening agent POE used is ethylene-octene copolymer, produced by Dow Company, and the brand name is Engage8150. The anti-wear agent used is Al2O3, with an average particle size of 2 microns, produced by Zhengzhou Xinli Wear-Resistant Material Company; the main antioxidant used is 1010, produced by BASF, and the trade name is IRGANOX 1010; the auxiliary anti-oxidant used The oxygen agent is 168, produced by BASF, IRGAFOS 168; the light stabilizer used is 3808PP5 produced by Cytec; the lubricant used is calcium stearate (CaSt), and the silane coupling agent used is KH550.

[0025] Concrete embodiment 1-5 and comparative example 1-2 formula are as shown in table one below:

[0026] Table I

[0027] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com