Antibacterial styrene-acrylic emulsion, preparation method and application

A styrene-acrylic emulsion and emulsion technology, which is applied in the field of building decoration materials, can solve the problems of uneven dispersion and easy leakage of antibacterial additives, and achieve the effects of good dispersion and corrosion inhibition, not easy to leak out, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

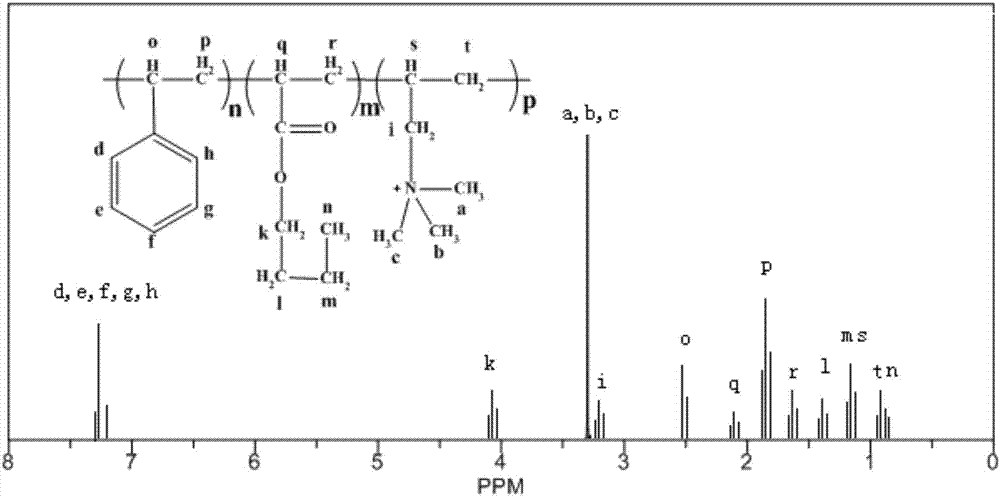

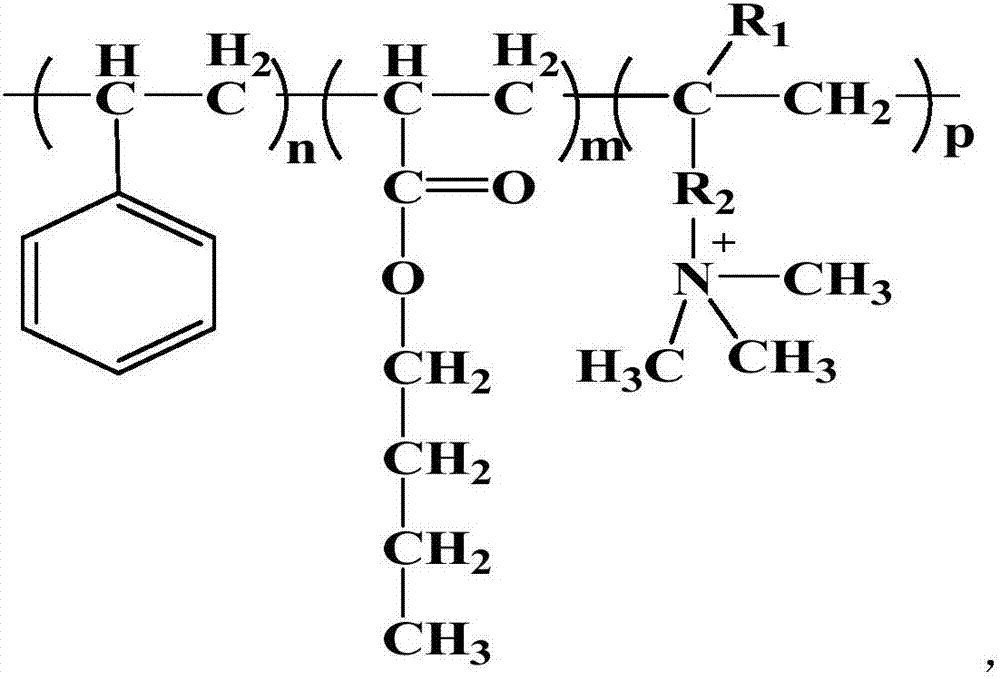

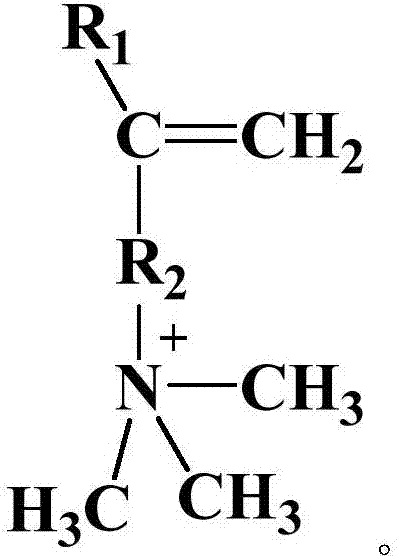

Method used

Image

Examples

Embodiment 1

[0030] The preparation process of the antibacterial styrene-acrylic emulsion of the present embodiment is as follows:

[0031] (1) Weigh 0.4g of sodium lauryl sulfate into a 50mL beaker, add 50mL of deionized water, heat slightly and stir manually to dissolve, then add 1g of OP-10 emulsifier, mix well, heat up to 75°C, Component 1 is obtained.

[0032] (2) Weigh 0.5g of ammonium persulfate into a 100mL beaker, add 10mL of deionized water, shake to dissolve, and obtain component 2;

[0033] (3) Weigh 0.2g of sodium bisulfite into a 100mL beaker, add 10mL of deionized water, shake to dissolve, and obtain component 3;

[0034] (4) Weigh 1g of acryloyloxyethyltrimethylammonium chloride, put it into a 50mL beaker, add 10mL of deionized water, shake to dissolve, and obtain component 4;

[0035] (5) Weigh 25 g of styrene and 25 g of butyl acrylate into a 500 mL beaker, and mix well to obtain component 5;

[0036] (6) In a four-necked bottle equipped with a stirrer, a thermometer, ...

Embodiment 2

[0041] The preparation process of the antibacterial styrene-acrylic emulsion of the present embodiment is as follows:

[0042] (1) Weigh 0.4g of sodium lauryl sulfate into a 50mL beaker, add 50mL of deionized water, heat slightly and stir manually to dissolve, then add 1g of OP-10 emulsifier, mix well to obtain component 1;

[0043] (2) Weigh 0.5g of ammonium persulfate into a 100mL beaker, add 10mL of deionized water, shake to dissolve, and obtain component 2;

[0044] (3) Weigh 0.2g of sodium bisulfite into a 100mL beaker, add 10mL of deionized water, shake to dissolve, and obtain component 3;

[0045] (4) Weigh 1g of allyltrimethylammonium chloride, put it into a 50mL beaker, add 10mL of deionized water, shake to dissolve, and obtain component 4;

[0046] (5) Weigh 25 g of styrene and 25 g of butyl acrylate into a 500 mL beaker, and mix well to obtain component 5;

[0047] (6) In a four-necked bottle equipped with a stirrer, a thermometer, a condenser and a dropping funne...

Embodiment 3

[0052]The preparation process of the antibacterial styrene-acrylic emulsion of the present embodiment is as follows:

[0053] (1) Weigh 0.4g of sodium lauryl sulfate into a 50mL beaker, add 50mL of deionized water, heat slightly and stir manually to dissolve. Then add 1g of OP-10 emulsifier and mix well to obtain component 1;

[0054] (2) Weigh 0.5g of ammonium persulfate into a 100mL beaker, add 10mL of deionized water, shake to dissolve, and obtain component 2;

[0055] (3) Weigh 0.2g of sodium bisulfite into a 100mL beaker, add 10mL of deionized water, shake to dissolve, and obtain component 3;

[0056] (4) Weigh 2g of acryloyloxyethyltrimethylammonium chloride into a 50mL beaker, add 10mL of deionized water, shake to dissolve, and obtain component 4;

[0057] (5) Weigh 25 g of styrene and 25 g of butyl acrylate into a 500 mL beaker, and mix well to obtain component 5;

[0058] (6) In a four-necked bottle equipped with a stirrer, a thermometer, a condenser and a dropping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com